Functions

7.9 Technological functions

Inverter with CU240B-2 and CU240E-2 Control Units

194 Operating Instructions, 07/2010, FW 4.3.2, A5E02299792B AA

7.9.1.4 Dynamic braking

Dynamic braking is typically used in applications in which dynamic motor behavior is

required at different speeds or continuous direction changes, e.g.:

● Horizontal conveyors

● Vertical and inclined conveyors

● Hoisting gear

Principle of operation

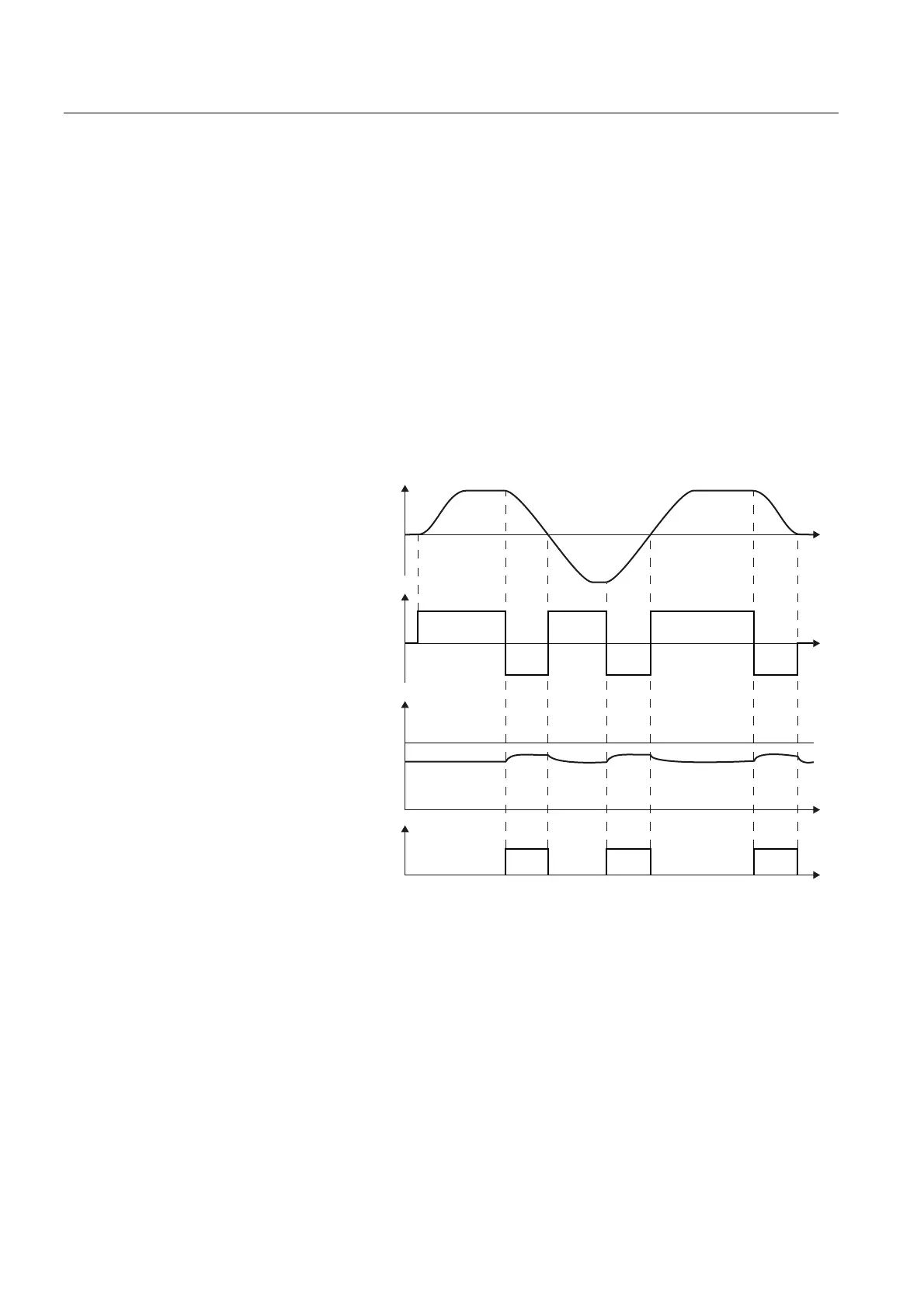

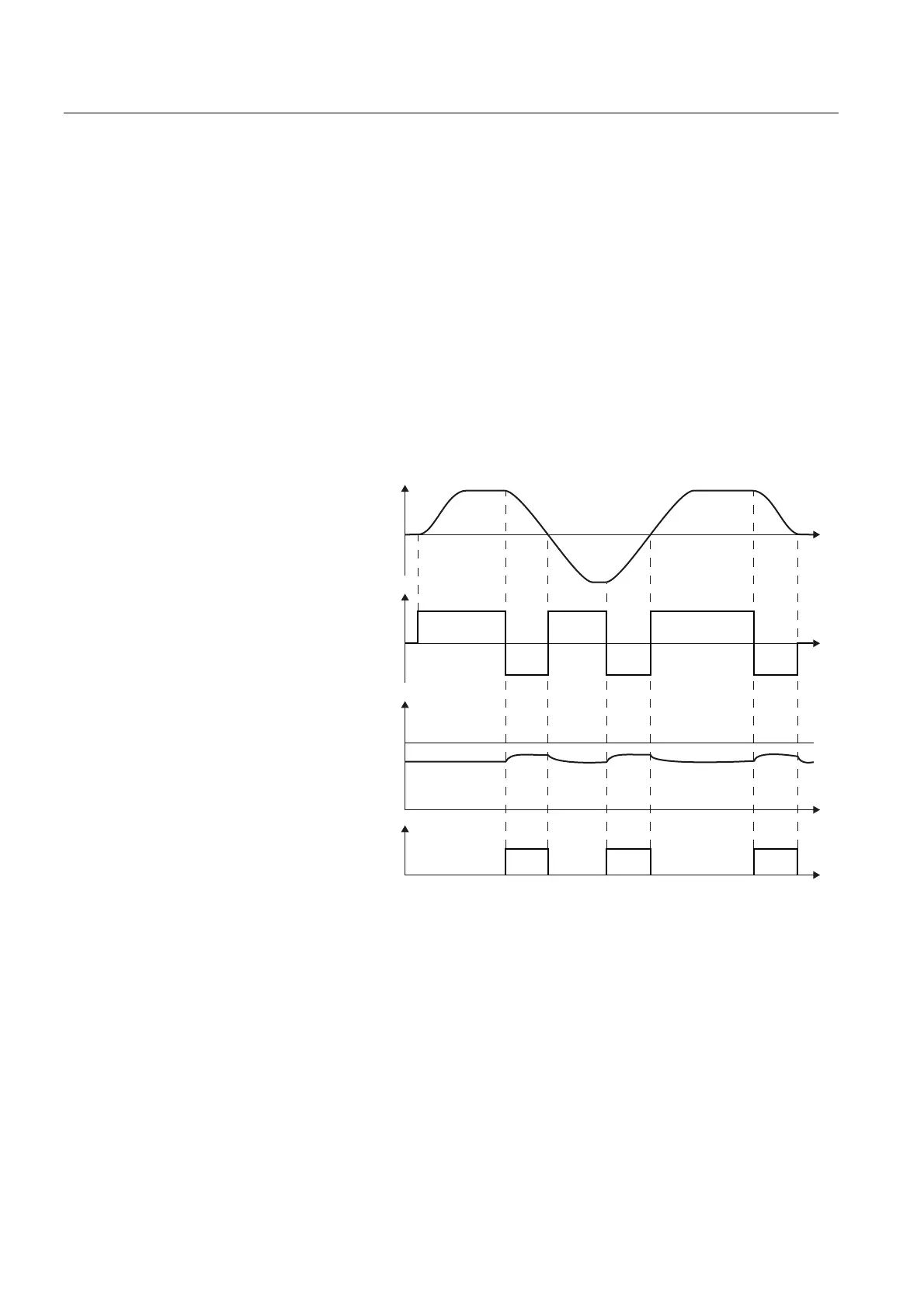

The inverter controls the braking chopper depending on its DC link voltage. The DC link

voltage increases as soon as the inverter absorbs the regenerative power when braking the

motor. The braking chopper converts this power into heat in the braking resistor. This

therefore prevents the DC link voltage increasing above the limit value V

DC link, max

.

%UDNLQJFKRSSHUDFWLYH

0RWRUSRZHU

PRWRULQJ

5HJHQHUDWLQJ

6SHHGDFWXDOYDOXH

U

'&OLQNYROWDJH9

DC link

U

9

DC link, max

W

W

W

W

Figure 7-10 Simplified representation of dynamic braking with respect to time

Braking resistor connection

● Connect the braking resistor to terminals R1 and R2 of the Power Module

● Ground the braking resistor directly to the control cabinet's grounding bar. The braking

resistor must not be grounded via the PE terminals on the Power Module

Loading...

Loading...