Configuration

3.3 Configuring the hydraulics

Hydraulic Drive

System Manual, 04/2015, 6SL3097-4BA00-0BP1

49

Classic servo valves with fluid converters as initial stages are extremely sensitive to

pollution. However, even the control edges of modern servo solenoid valves require filtration.

To ensure general operational reliability, but more importantly, to protect the control edges

against premature erosion and to maintain the quality of zero overlap, the oil pollution must

be limited in compliance with Class 7 to 9 according to NAS 1638.

This is achieved by using for instance full flow filters, which must be located in the pressure

line directly upstream of the servo solenoid valve.

Commissioning is the most critical phase, as pollution frequently results in failures. For this

reason, it is advisable to purge the system before the servo solenoid valves are fitted.

Since considerable power losses occur when the flow is throttled using the control edges on

the valve, which cannot be compensated for solely through heat radiated from the oil

reservoir, additional oil/air or oil/water heat exchangers must be provided in most cases.

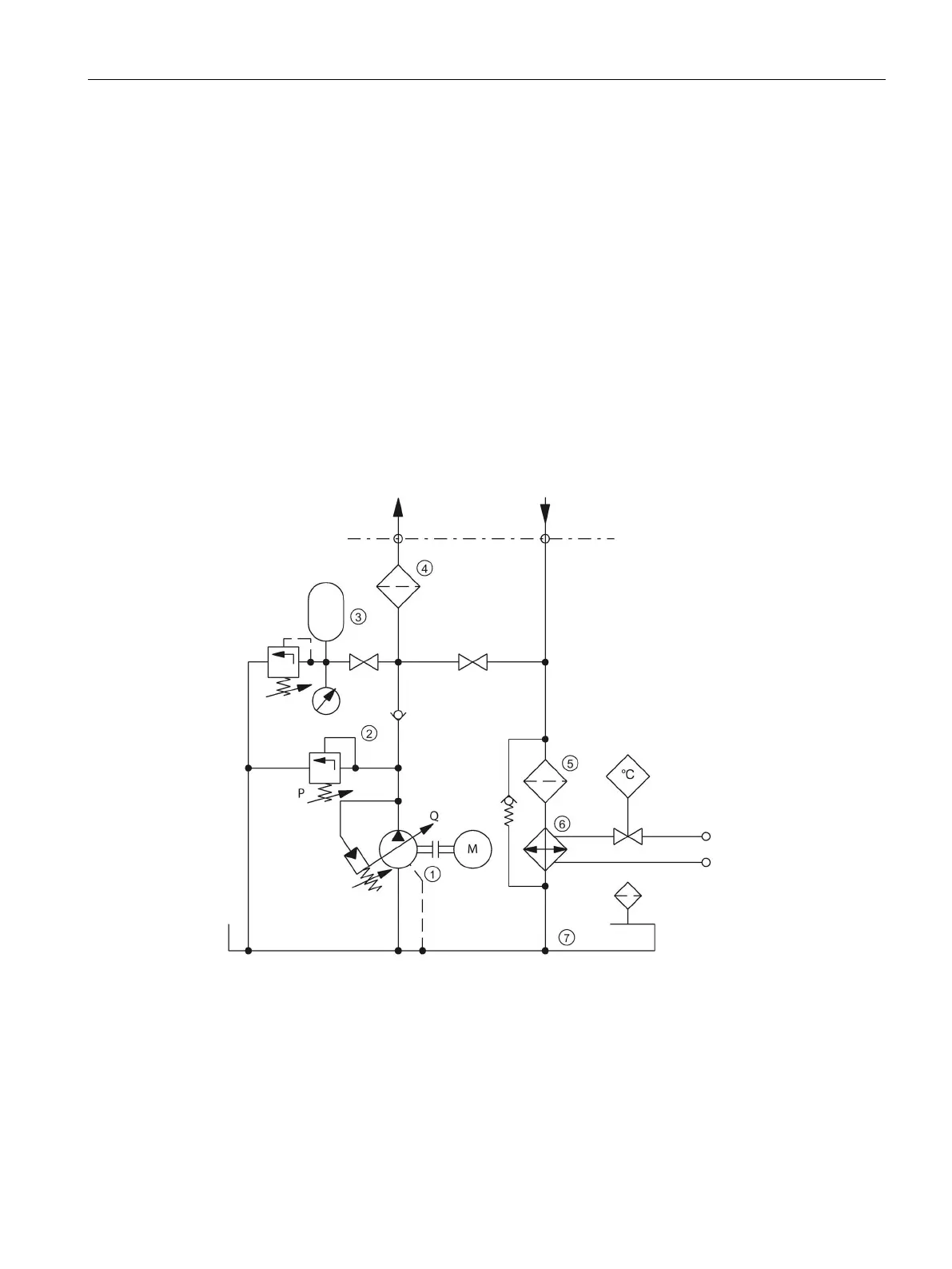

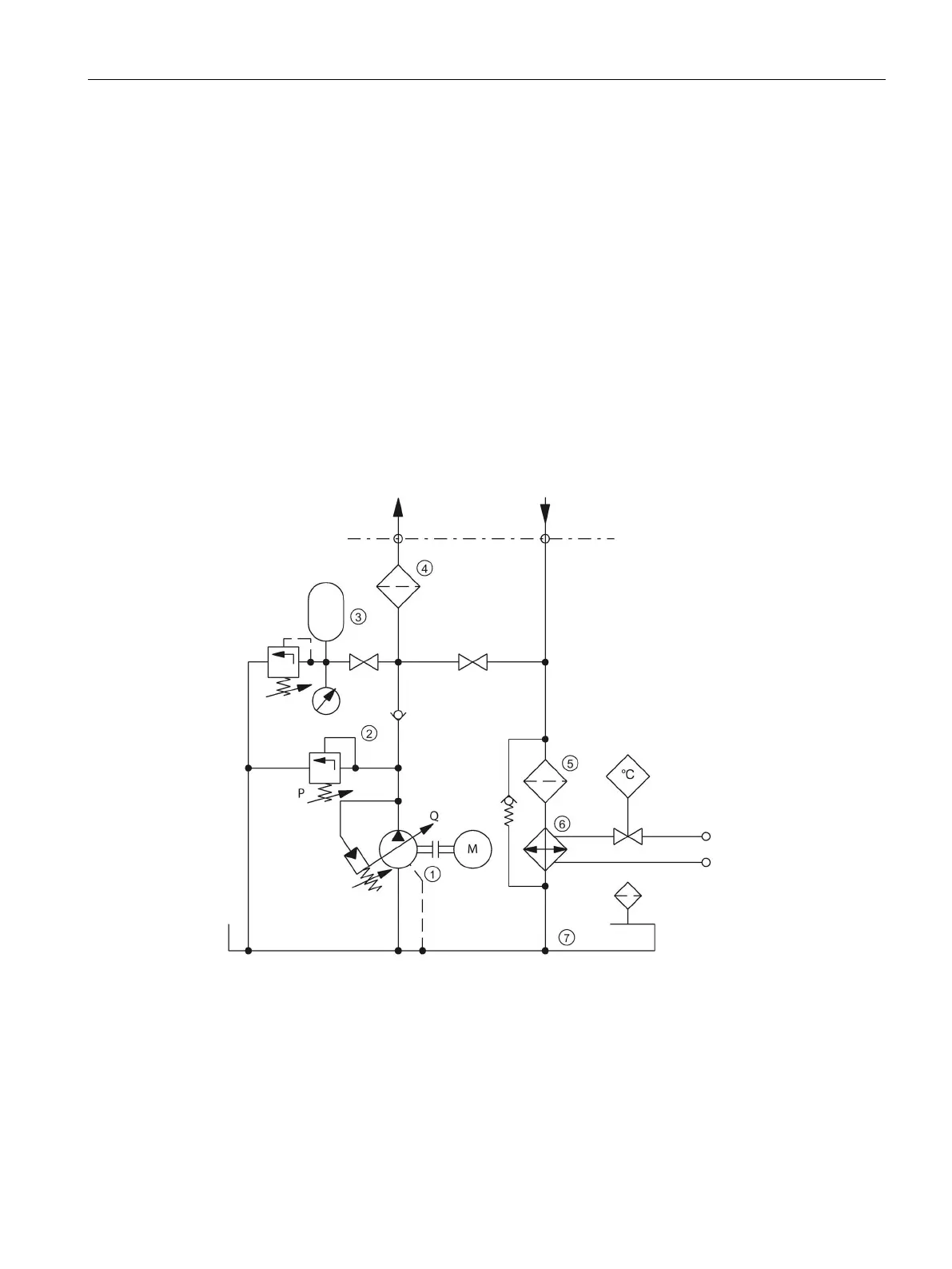

Variable displacement pump with pressure

Filters in the return line

Pressure-relief valve (protection)

Accumulator with safety circuit

Filters in the pressure line

Figure 3-6 Overview of a typical hydraulic power unit

Loading...

Loading...