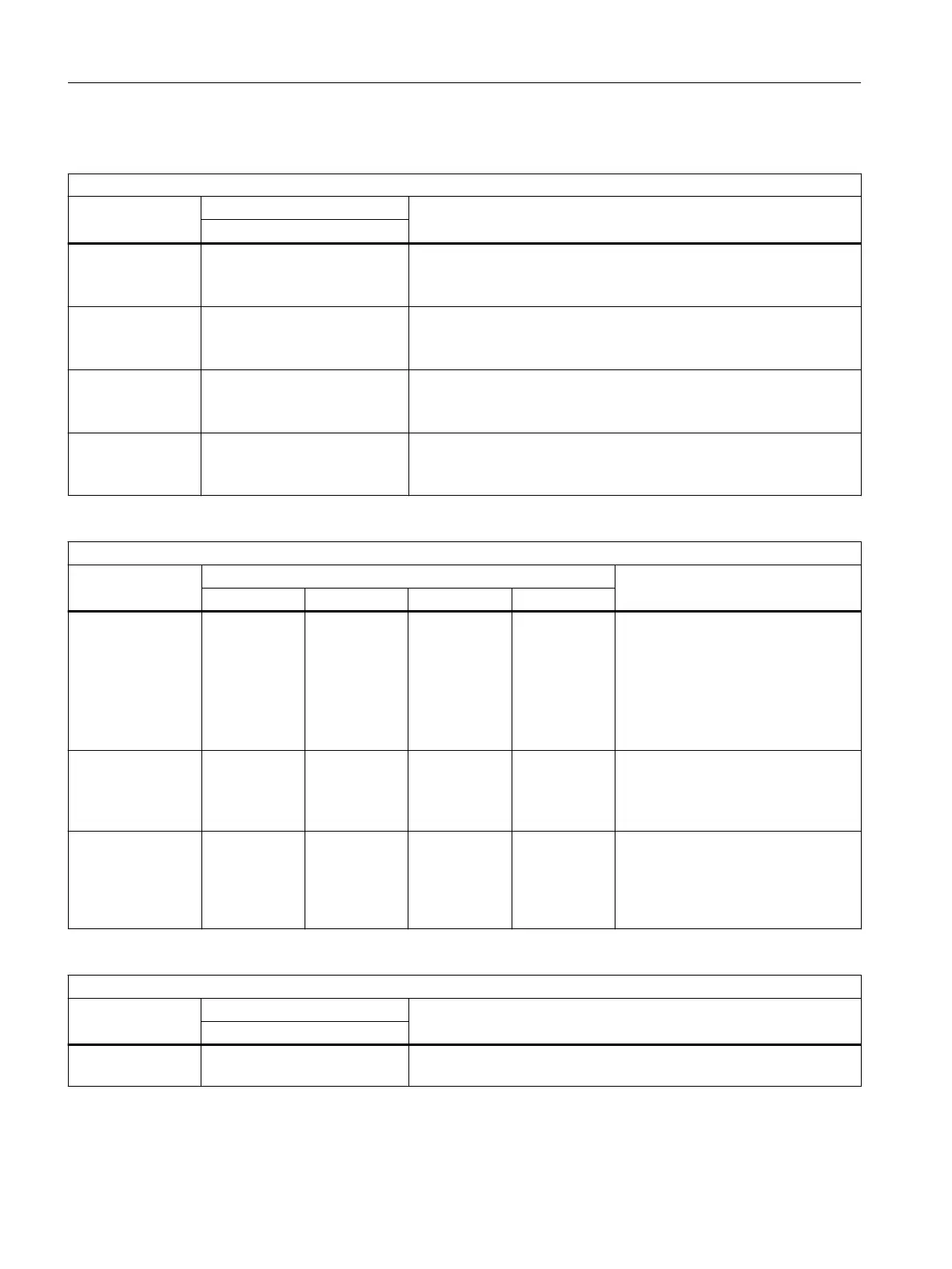

Grinding

Identifier Parameter Explanation

1.

GWPSON INT:

Spindle number

Constant grinding wheel peripheral speed ON

If the spindle number is not programmed, the grinding wheel peripheral

speed for the spindle of the active tool is selected.

GWPSOF INT:

Spindle number

Constant grinding wheel peripheral speed OFF

If the spindle number is not programmed, the grinding wheel peripheral

speed for the spindle of the active tool is deselected.

TMON INT:

T number

Grinding-specific tool monitoring ON

If no T number is programmed, monitoring is activated for the active

tool.

TMOF INT:

T number

Tool monitoring OFF

If no T number is programmed, monitoring is deactivated for the active

tool.

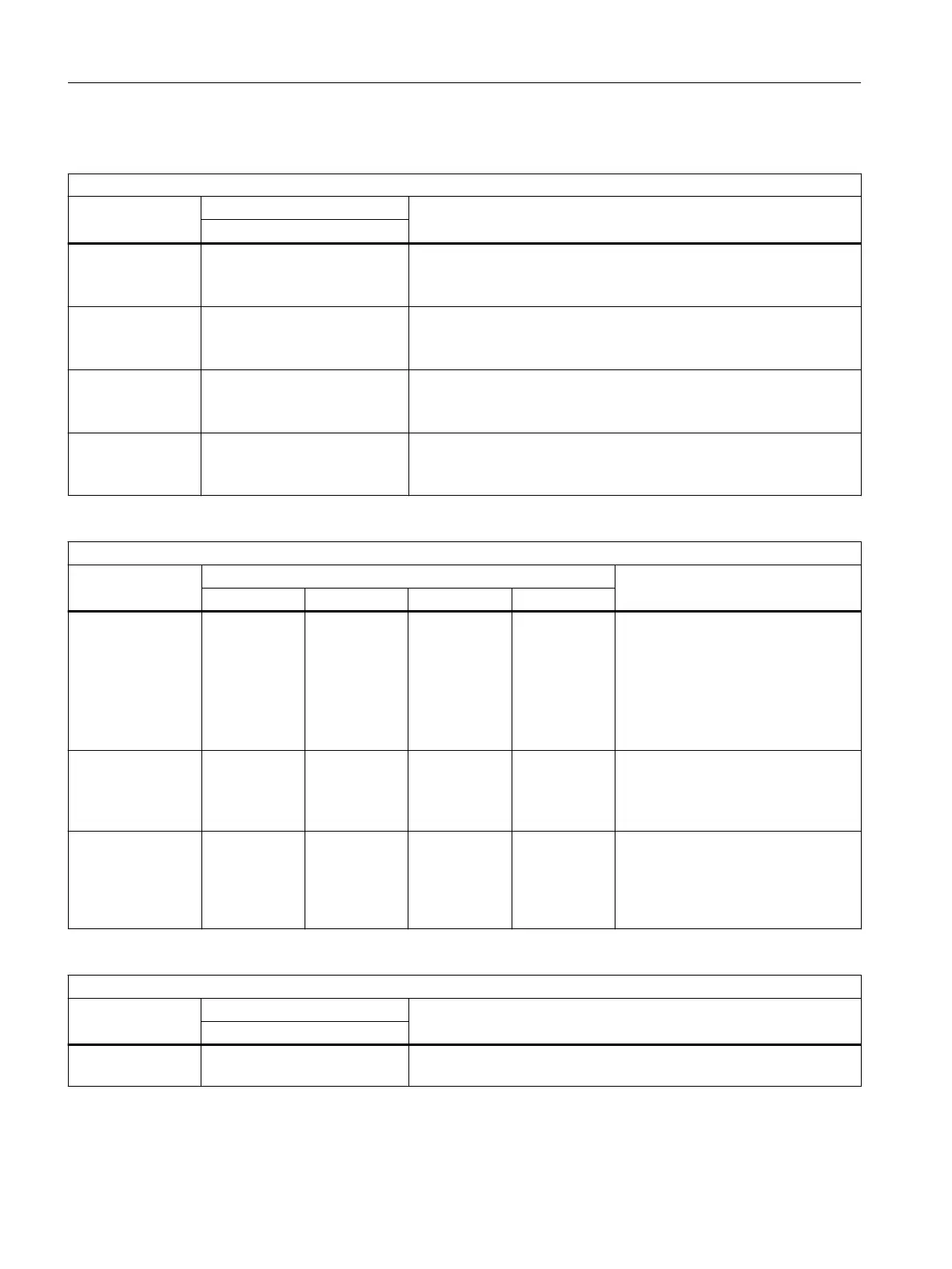

Stock removal

Identifier Parameter Explanation

1. 2. 3. 4.

CONTPRON REAL [ ,11]:

Contour table

CHAR: Ma‐

chining type

INT:

Number of re‐

lief cuts

INT:

Status of the

calculation

Activate reference preprocessing

The contour programs or NC blocks

which are called in the following

steps are divided into individual

movements and stored in the contour

table.

The number of relief cuts is returned.

CONTDCON REAL [ , 6]:

Contour table

INT:

Machining di‐

rection

Contour decoding

The blocks for a contour are stored in

a named table with one table line per

block and coded to save memory.

EXECUTE INT: Error sta‐

tus

Activate program execution

This switches back to normal pro‐

gram execution from reference point

editing mode or after setting up a pro‐

tection area.

Execute table

Identifier Parameter Explanation

1.

EXECTAB REAL [ 11]:

Element from motion table

Execute an element from a motion table

Tables

4.4 Predefined procedures

NC programming

1272 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...