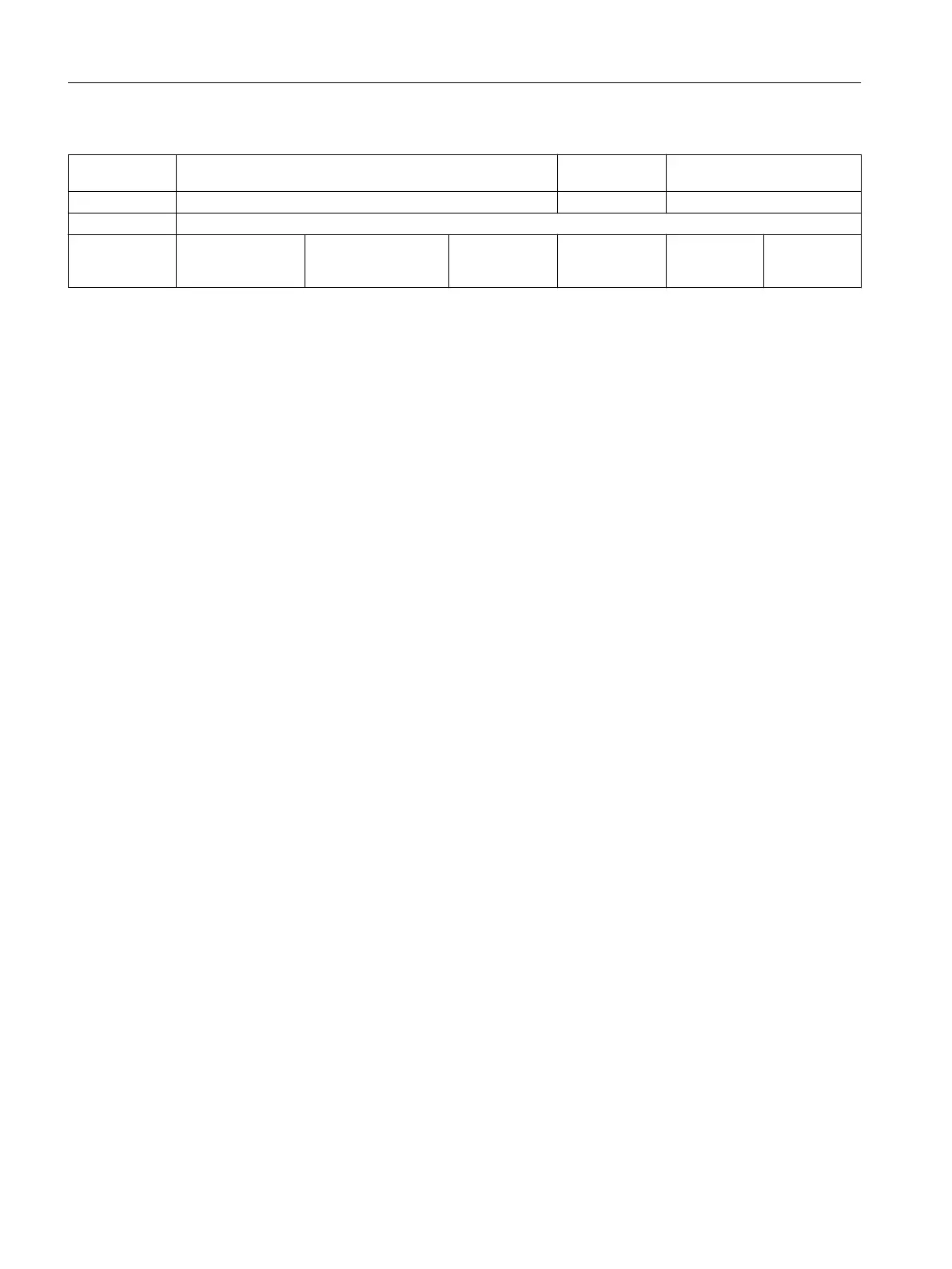

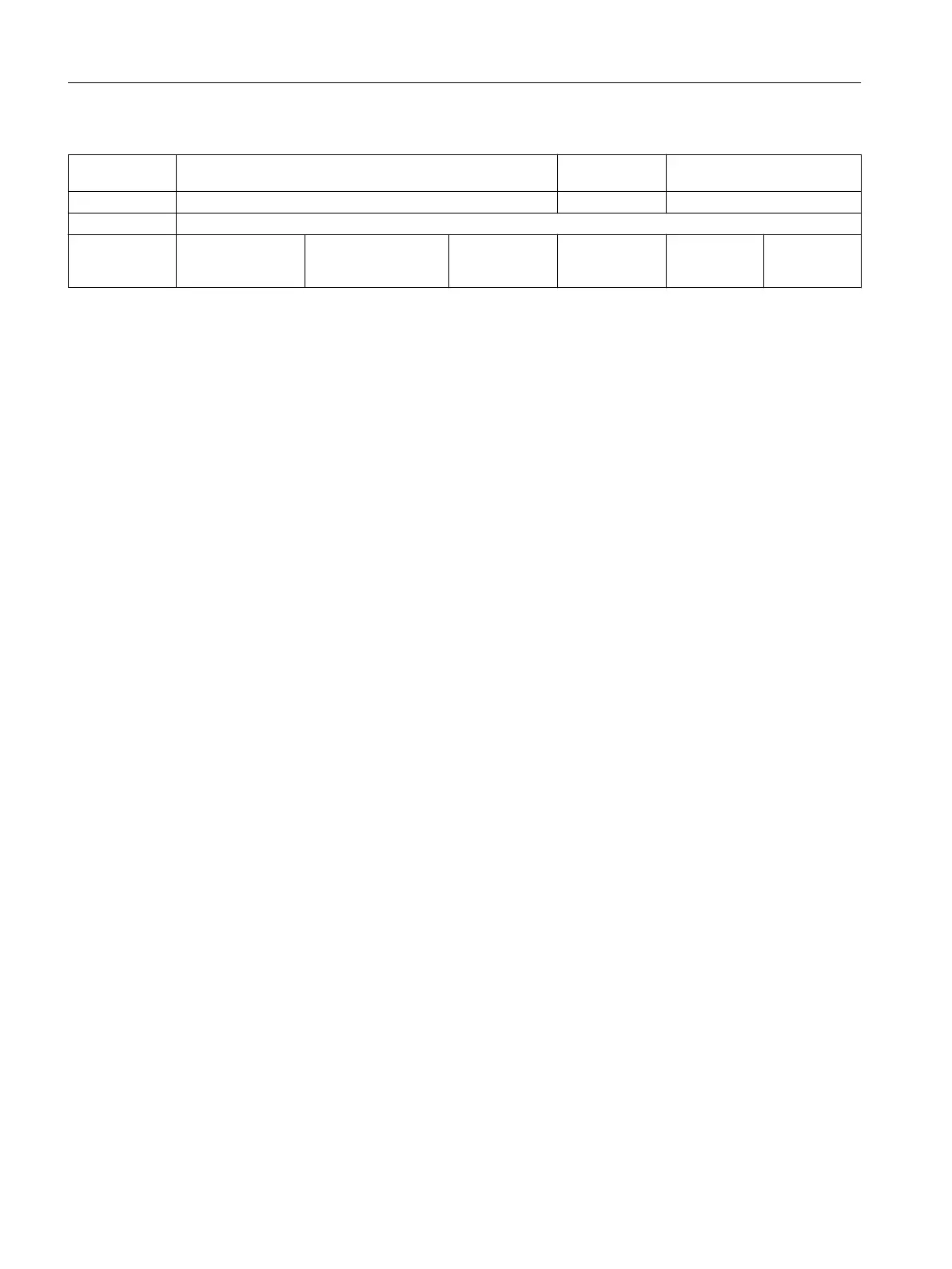

20112 START_MODE_MASK C03 K6, M3, K5, M1, K1, K2, P1, S1,

W1

- Definition of basic setting of control after part program start DWORD Reset

-

- - 0x400, 0x400, 0x400,

0x400, 0x400, 0x400,

0x400, 0x400...

0 0x7FFFF 1/1 M

Description: Definition of the initial setting of the control at the start of the part program with

respect to G

codes (in particular, active plane and active settable work offset), tool

length offset, transformation, and axis couplings by setting the following bits:

Bit 0: Not assigned: MD20112 $MC_START_MODE_MASK is evaluated every time a part

program starts

Bit 1: Suppress aux. funct. output on tool selection

Bit 2: Not assigned, but reserved (see corresponding bit in RESET_MODE_MASK)

Bit 3: Not assigned, but reserved (see corresponding bit in RESET_MODE_MASK)

Bit 4: Start response for G code "Current plane"

Bit 5: Start response for G code "Settable work offset"

Bit 6: Start response for "Active tool length offset"

Bit 7: Start response for "Active kinematic transformation"

Bit 8: Start response for "Coupled-motion axes"

Bit 9: Start response for "Tangential correction"

Bit 10: Start response for "Synchronous spindle"

Bit 11: Not assigned, but reserved (see corresponding bit in RESET_MODE_MASK)

Bit 12: Start response for "Geo axis replacement"

Bit 13: Start response for "Master value coupling"

Bit 14: Not assigned, but reserved (see corresponding bit in RESET_MODE_MASK)

Bit 15: Not assigned, but reserved (see corresponding bit in RESET_MODE_MASK)

Bit 16: Start response for "Master spindle"

Bit 17: Start response for "Master toolholder"

Bit 18: Start response for "Reference axis for G96/G961/G962"

Bit 19: Reserved "Adjustable software limit switch ineffective"

Bit 20: Reserved "$P_USEKT reset response"

Meaning of individual bits:

Bit 1 = 0:

Auxiliary function output (D, T, M, DL) to PLC on tool selection according to the

following MDs: MD20120 $MC_TOOL_RESET_VALUE, MD20130 $MC_CUTTING_EDGE_RESET_VALUE,

MD20121 $MC_TOOL_PRESEL_RESET_VALUE, and MD22550 $MC_TOOL_CHANGE_MODE.

Note:

If tool or magazine management is active, only auxiliary functions D and DL are

output.

Bit 1 = 1:

Suppress auxiliary function output to PLC on tool selection.

Bit 1 is not relevant if tool or magazine management is active.

Bit 2 : Reserved (reset response after power-on)

Bit 3 : Reserved (end of test mode)

Bit 4 = 0:

The current setting for G code "current plane" is retained.

Bit 4 = 1:

Initial setting for G code "current plane" according to MD20150 $MC_GCODE_RESET_VALUES

Bit 5 = 0:

Machine data

3.3 Channel-specific machine data

Parameter Manual

124 Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1

Loading...

Loading...