With spindles, this MD refers to the lower of the speeds set in

MD35130 $MA_GEAR_STEP_MAX_VELO_LIMIT of the current gear stage and MD35100

$MA_SPIND_VELO_LIMIT.

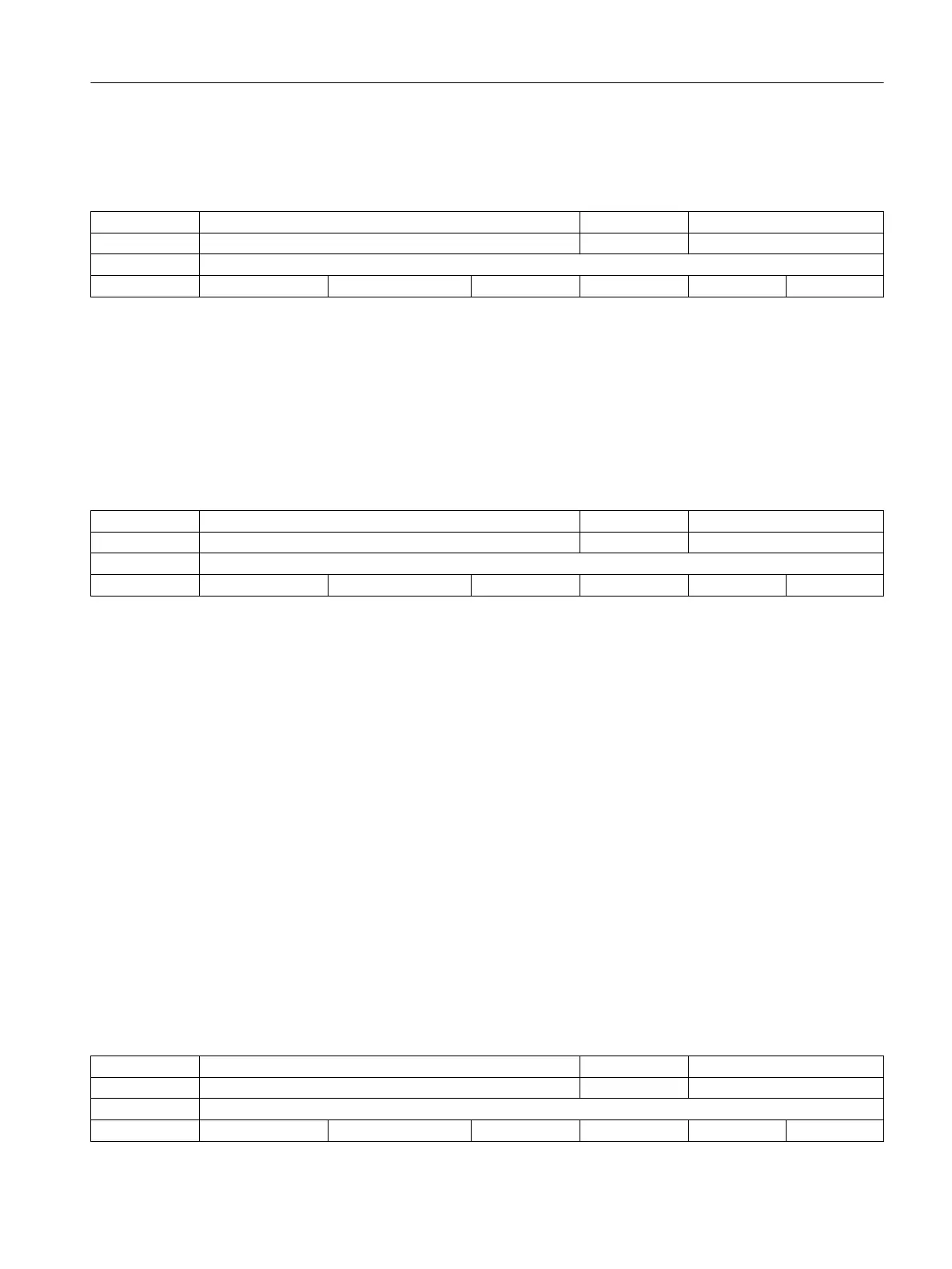

36600 BRAKE_MODE_CHOICE EXP, A05 A3, Z1

- Deceleration response on hardware limit switch BYTE PowerOn

CTEQ

- - 0 0 1 2/2

Description: If a rising edge of the axis-specific hardware limit switch is detected while the axis

is traversing, the axis is braked immediately.

The type of braking is determined by this machine data:

Value = 0:

Controlled braking along the acceleration ramp defined by MD32300 $MA_MAX_AX_ACCEL

(axis acceleration).

Value = 1:

Rapid braking (selection of setpoint = 0) with reduction of following error.

Related to:

NC/PLC interface signal DB380x DBX1000.1 und .0 (Hardware limit switch plus or minus)

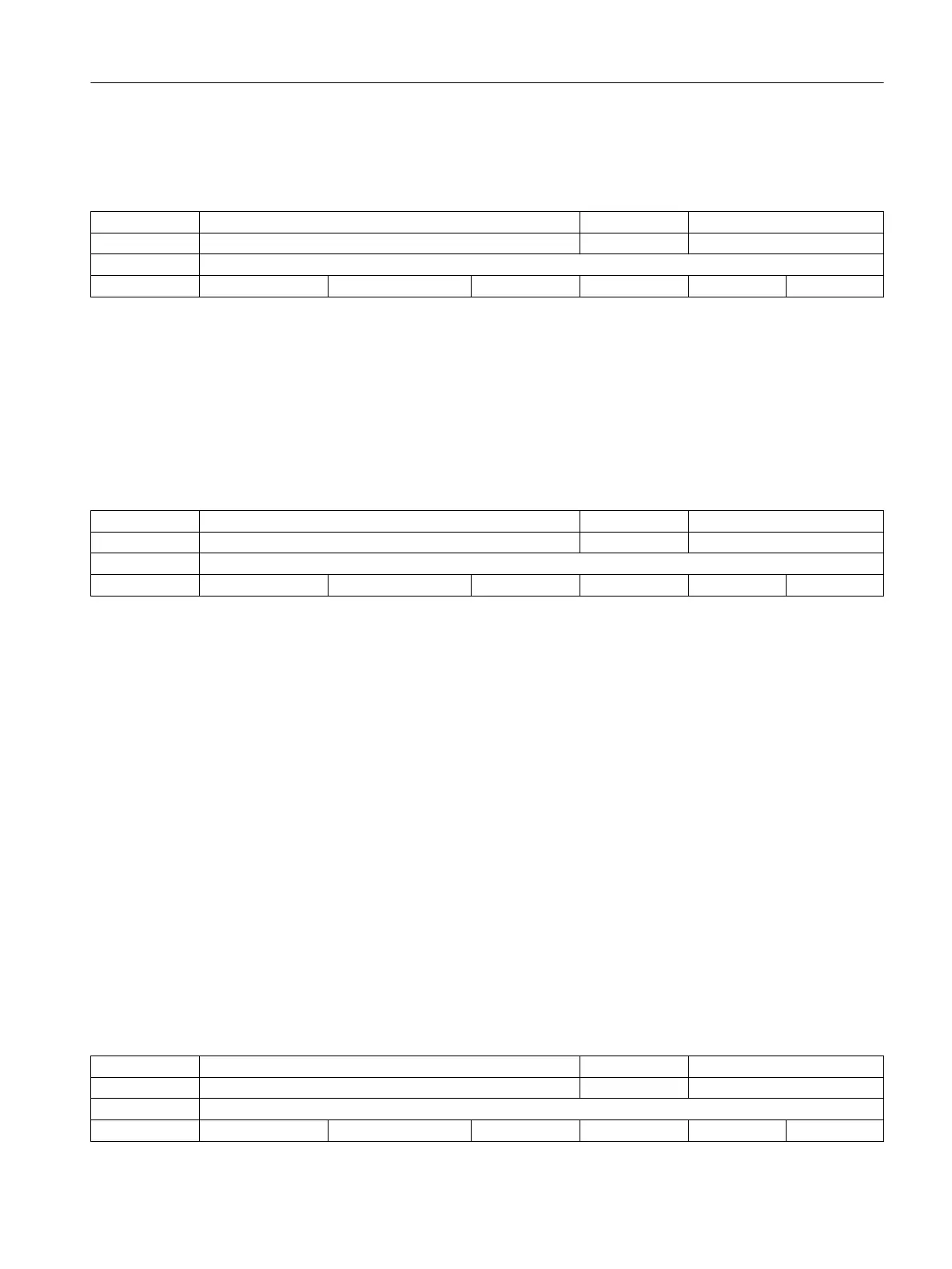

36610 AX_EMERGENCY_STOP_TIME A05 TE3, K3, A2, A3, N2, Z1

s Maximum time for braking ramp in case of error. DOUBLE NEW CONF

-

- - 0.05 0.0 1.0e15 2/2

Description: This MD defines the braking ramp time that an axis or spindle requires to brake from

maximum velocity/speed to a standstill in the event of errors (e.g. emergency stop).

At the same lead/brake acceleration, standstill is reached correspondingly earlier

from lower velocities/speeds.

Mechanically robust axes are normally stopped abruptly with speed setpoint 0; values

in the lower ms range are appropriate in these cases (default setting).

However, high moving masses or limited mechanical conditions (e.g. gear load capacity)

often have to be taken into account for spindles. This means that the MD has to be

changed to set a longer braking ramp.

Notice:

● With interpolating axes or axis/spindle couplings, it cannot be ensured that the

contour or coupling will be maintained during the braking phase.

● If the time set for the braking ramp for error states is too long, the controller

enable

will be

removed although the axis/spindle is still moving. Depending on the

drive type used and the activation of the pulse enable, either an immediate stop

with speed setpoint 0 will be initiated or the axis/spindle will coast down without

power. The time selected in MD36610 $MA_AX_EMERGENCY_STOP_TIME should therefore be

shorter than the time in MD36620 $MA_SERVO_DISABLE_DELAY_TIME (cutout delay,

controller enable) so that the configured braking ramp can be fully active

throughout the entire braking operation.

● The braking ramp may be ineffective or not maintained if the active drive follows

its own braking ramp logic (e.g. SINAMICS).

Related to:

MD36620 $MA_SERVO_DISABLE_DELAY_TIME (cutout delay controller enable)

MD36210 $MA_CTRLOUT_LIMIT (maximum speed setpoint)

36620 SERVO_DISABLE_DELAY_TIME A05 TE3, K3, A2, A3, N2, Z1

s Cutout delay servo enable DOUBLE NEW CONF

-

- - 0.1 0.0 1.0e15 2/2

Machine data

3.4 Axis-specific machine data

Parameter Manual

Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1 291

Loading...

Loading...