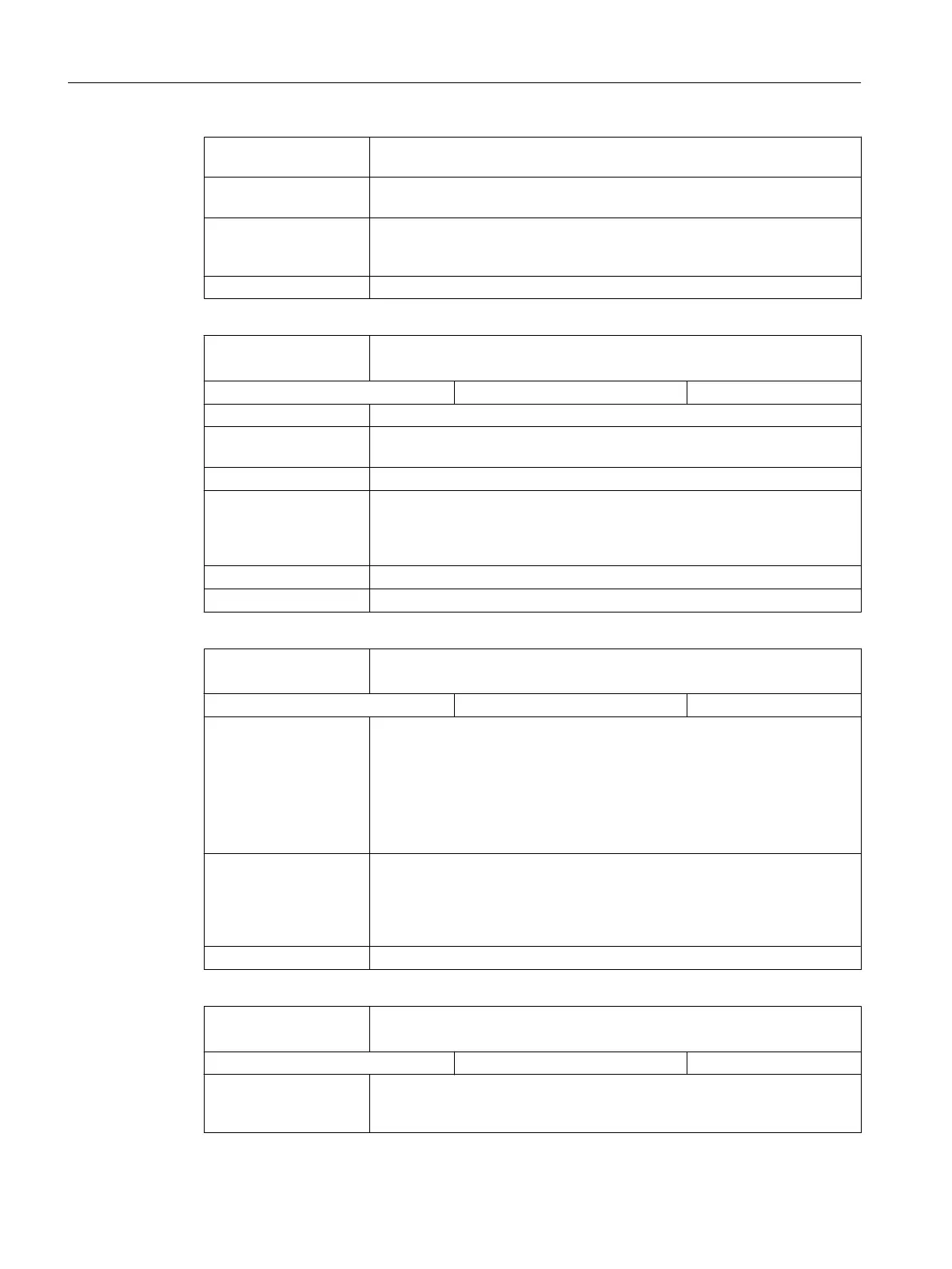

Signal state 1 or edge

change 0 → 1

Instead of the value for "Spindle override" the value of "feedrate override"

(DB380x DBB0) is used for the spindle.

Signal state 0 or edge

change 1 → 0

The value of "spindle override" is used.

corresponding to ... IS"Spindle override" (DB380x DBB2003)

IS"Feedrate override" (DB380x DBB0)

IS"Override active" (DB380x DBX1.7)

Note for the reader Function Manual Basic Functions V1

DB380x

DBX2001.4

Re-synchronize spindle during positioning 1

Signal(s) to axis / spindle (PLC → NCK)

Edge evaluation: Yes Signal(s) updated: Cyclic

Signal state 1 When positioning, the spindle must be re-synchronized.

Signal state 0 or edge

change 1 → 0

No effect

Signal irrelevant for ... ... spindle modes other than the positioning mode

Application The spindle has an indirect measuring system and slip may occur between

the motor and clamp. If the signal = 1, when positioning is started, the old

reference

is deleted

and the zero mark is searched for again before the end

position is approached.

corresponding to ... IS "Referenced / synchronized 1" (DB390x DBX0.4)

Note for the reader Function Manual Basic Functions S1

DB380x

DBX2001.6

Invert M3/M4

Signal(s) to axis / spindle (PLC → NCK)

Edge evaluation: Yes Signal(s) updated: Cyclic

Signal state 1 or edge

change 0 → 1

The direction of rotation of the spindle motor changes for the following func‐

tions:

●

M3

● M4

●

M5

● SPOS from the motion; not active for SPOS from standstill

Application The machine has a selector switch for a vertical and horizontal spindle. The

mechanical design is implemented so that for the horizontal spindle, one

more gearwheel is engaged than for the vertical spindle. The direction of

rotation must therefore be changed for the vertical spindle if the spindle is

always to rotate clockwise with M3.

Note for the reader Function Manual Basic Functions S1

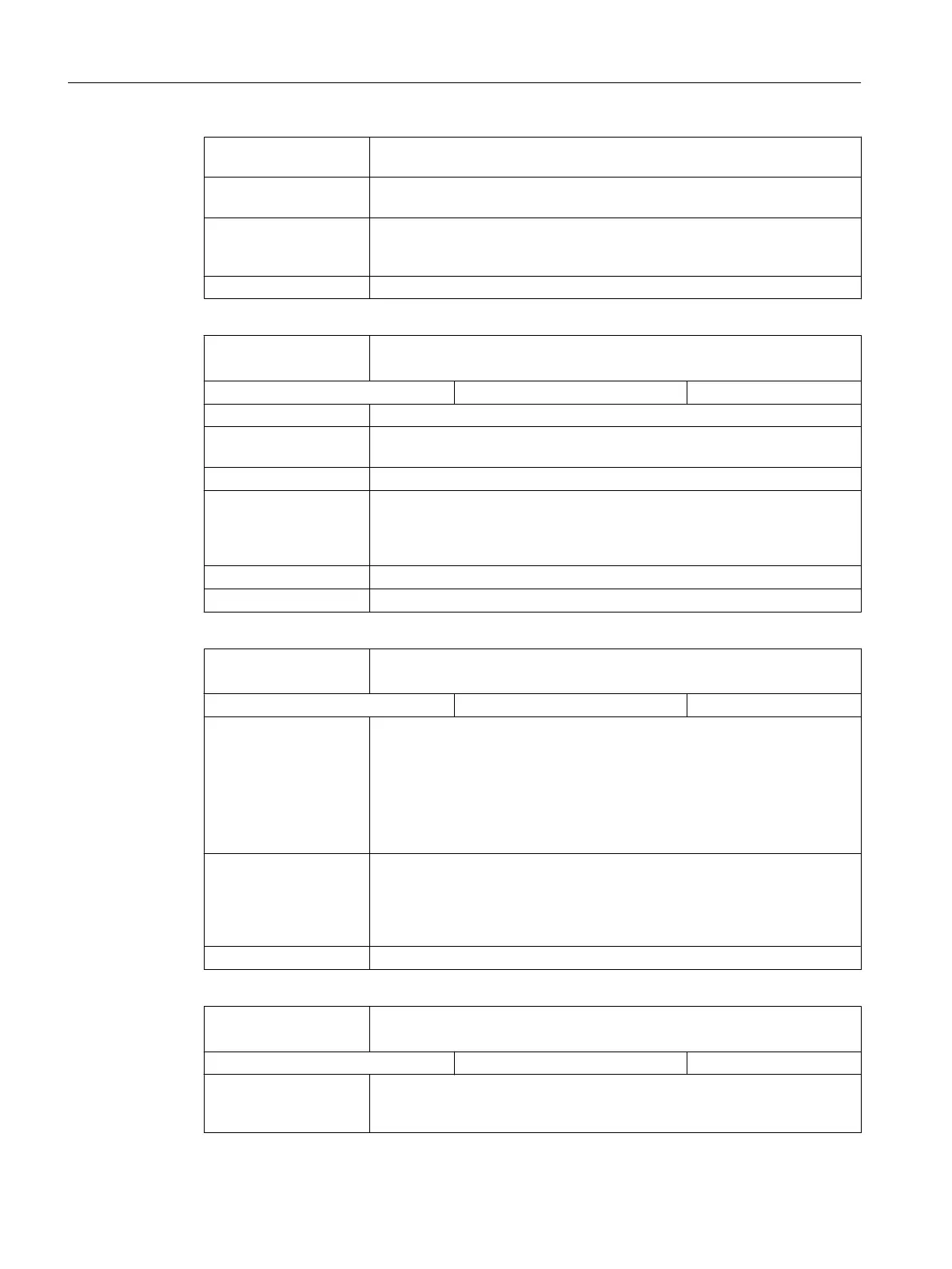

DB380x

DBX2002.4

Oscillation via PLC

Signal(s) to axis / spindle (PLC → NCK)

Edge evaluation: Yes Signal(s) updated: Cyclic

Signal state 1 or edge

change 0 → 1

If the IS "Oscillation via PLC" is set, then with the IS "Oscillation speed", a

speed is output in conjunction with the IS "Setpoint direction of rotation,

clockwise and counter-clockwise).

Detailed descriptions of interface signals

5.8 Axis / spindle-specific signals

Parameter Manual

422 Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1

Loading...

Loading...