Machine data

2.3 Channel-specific machine data

Parameter Manual

146

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

Description:

Bit 0 = 0:

When bit 19 is also set to '0' in MD35035 $MA_SPIND_FUNCTION_MASK, auxiliary

function M19 is not generated with SPOS and SPOSA. This also eliminates the

acknowledgement time for the auxiliary function, which can cause faults wiith

very short blocks.

Bit 0 = 1:

When SPOS and SPOSA are programmed in the part program, auxiliary function

M19 is generated and output to the PLC. The address extension corresponds to

the spindle number.

Related to:

SPIND_FUNCTION_MASK

Description: This machine data is used to specify the permissible absolute circle error

[mm].

When a circle is programmed, both conditions (that the distances from the

programmed center point to the start and end points (circle radius) must be

the same and that the center point of the circle must be located on the per-

pendicular bisector of the straight line connecting the start and end points

(perpendicular bisector of the circular plane)) apply.

The fact that the circular parameters can be freely programmed means that

these conditions are not usually met exactly in the case of circular-path

programming with I, J, and K (the circle is "overdefined").

The maximum permissible difference between the two radii that is accepted

without an alarm, as well as the distance between the programmied center

point of the circle and the perpendicular bisector described above, is

defined by the larger value in the following data:

• MD21000 $MC_CIRCLE_ERROR_CONST

• Start radius multiplied by MD21010 $MC_CIRCLE_ERROR_FACTOR

This means that for small circles the tolerance is a fixed value (MD21000

$MC_CIRCLE_ERROR_CONST), and for large circles it is proportional to the

start radius.

Related to:

MD21010 $MC_CIRCLE_ERROR_FACTOR

(circle end point monitoring factor)

In the context of the predefined tolerances, conflicting circle data is com-

pensated essentially by moving the center point of the circle. Please note

that the deviation between the programmed center point and the actual center

point can reach the order of magnitude set with machine data MD21000

$MC_CIRCLE_ERROR_CONST and/or MD21010 $MC_CIRCLE_ERROR_FACTOR. In the case

of circles which are almost full circles in particular, this can also lead to

contour deviations of the same order of magnitude.

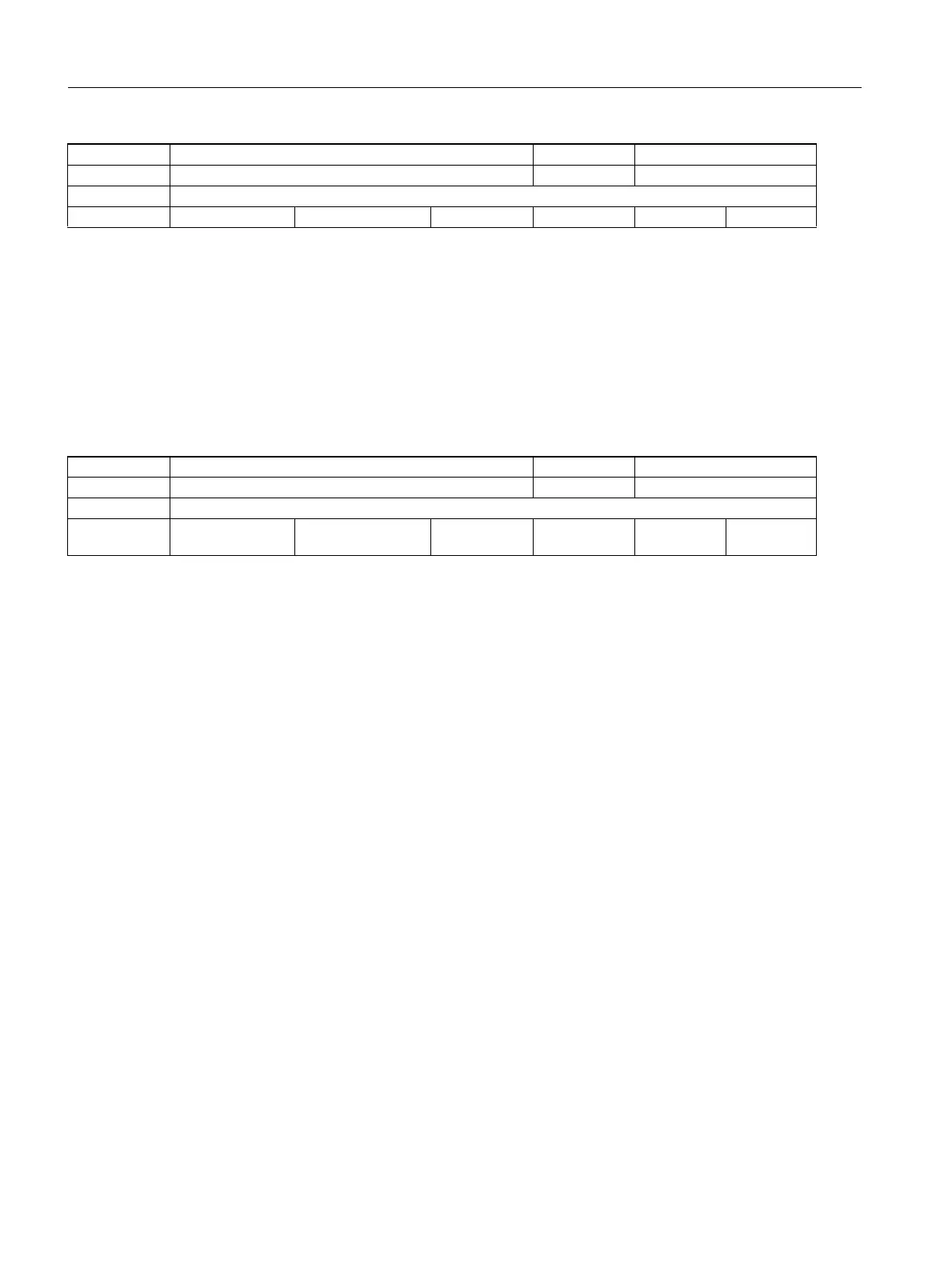

20850 SPOS_TO_VDI C04, C03 S1

- Output of M19 to PLC on SPOS/SPOSA BYTE PowerOn

-

- - 0, 0, 0, 0, 0, 0, 0, 0... - - 1/1

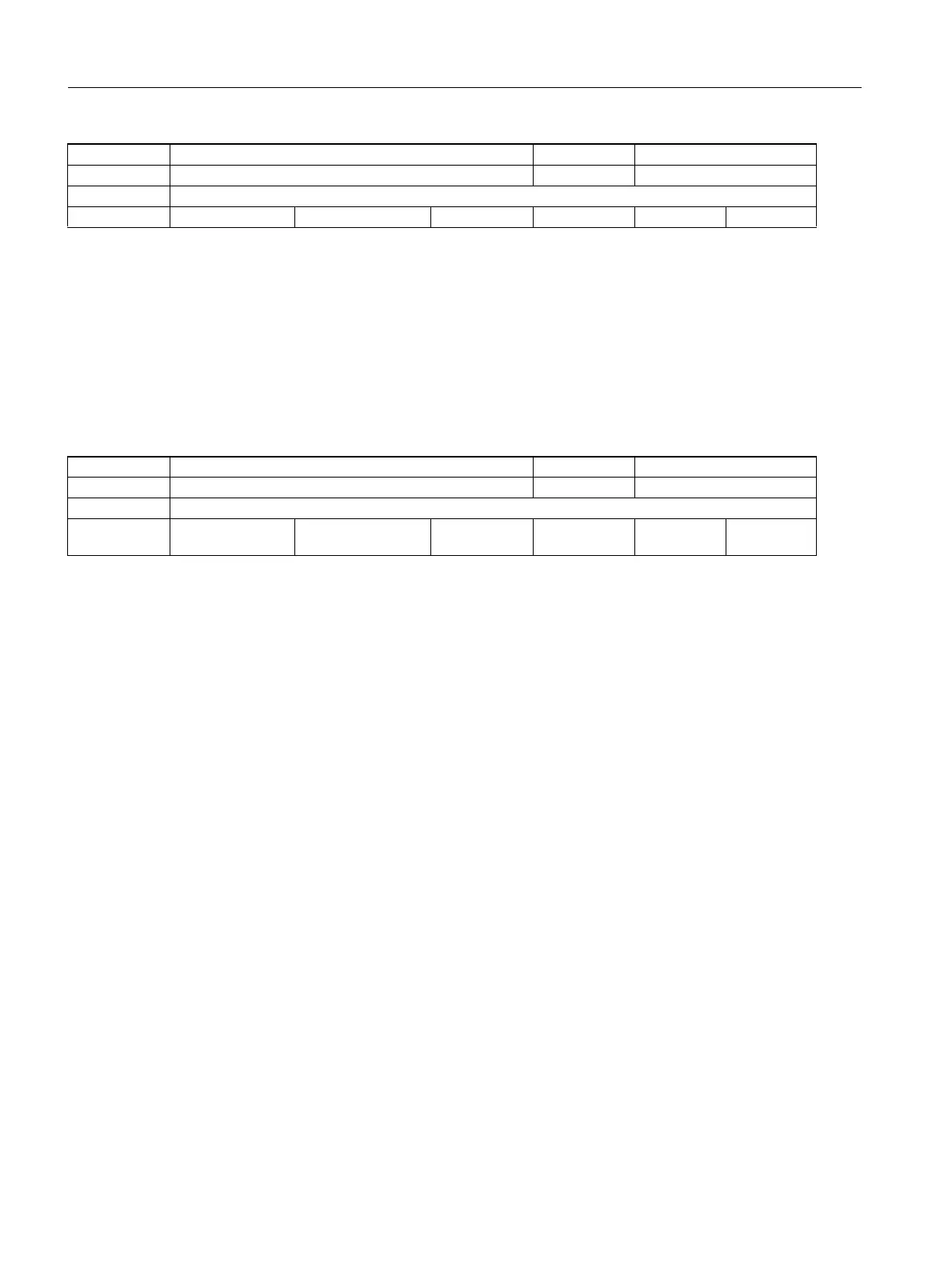

21000 CIRCLE_ERROR_CONST C06 -

mm Circle end point monitoring constant DOUBLE PowerOn

-

- - 0.01, 0.01, 0.01, 0.01,

0.01, 0.01, 0.01...

0.0 - 2/2

Loading...

Loading...