Parameter Manual

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

157

Machine data

2.3 Channel-specific machine data

Description: Behavior if faults/problems occur during programmed tool change.

Bit 0=0: Standard behavior: Stop at the faulty NC block

Bit 0=1: If a fault is detected in the block with the tool change prepara-

tion, the alarm relevant to the preparation command T is delayed until the

corresponding tool change command (M06) has been interpreted in the program

sequence. Until then, the alarm triggered by the preparation command is not

output. The operator can take corrective actions in this block. When the pro-

gram continues, the faulty NC block is re-interpreted, and the preparation

command is automatically executed again internally.

The value = 1 is relevant only if the setting MD22550 $MC_TOOL_CHANGE_MODE =

1 is used.

Bit 1 Only relevant with active tool management.

Bit 1=0: Standard behavior: Only tools with data assigned to a magazine are

detected during tool change preparation.

Bit 1=1: Manual tools can be loaded.

A tool will also be loaded if its data is known in the NCK but has not been

assigned to a magazine. In this case, the tool data is automatically assigned

to the programmed toolholder.

The user is prompted to insert tools into or remove tools from the tool-

holder.

Bit 2 qualifies the offset programming

Bit 2=0: active D no. > 0 and active T no.=0 gives offset 0

Active D no. > 0 and active D no.=0 gives total offset 0

Bit 2=1: active D no. > 0 and active T no.=0 lead to an alarm message

Active D no. > 0 and active D no.=0 lead to an alarm message

Bits 3 and 4 are only relevant with active tool management.

Function:

Control of the behavior of the init. block generation on program start if a

disabled tool is on the spindle and this tool is to be activated.

See also: MD20112 $MC_START_MODE_MASK, MD20110 $MC_RESET_MODE_MASK

On RESET, this does not affect the behavior "Keep disabled tool on the spin-

dle active".

Bit 3=0: Standard: If the tool on the spindle is disabled, generate a tool

change command requesting a replacement tool. An alarm will be generated if

there is no such replacement tool.

Bit 3=1: The disabled status of the spindle tool is ignored. The tool becomes

active. The subsequent part program should be formulated so that no parts are

machined with the disabled tool.

Bit 4=0: Standard: The system tries to activate the spindle tool or its

replacement tool

Bit 4=1: If the tool on the spindle is disabled, T0 is programmed in the

start init block.

The combination of bits 3 and 4 produces the following statements:

0 / 0: Behavior as before, automatic change on NC start if a disabled tool is

in the spindle

1 / 0: No automatic change

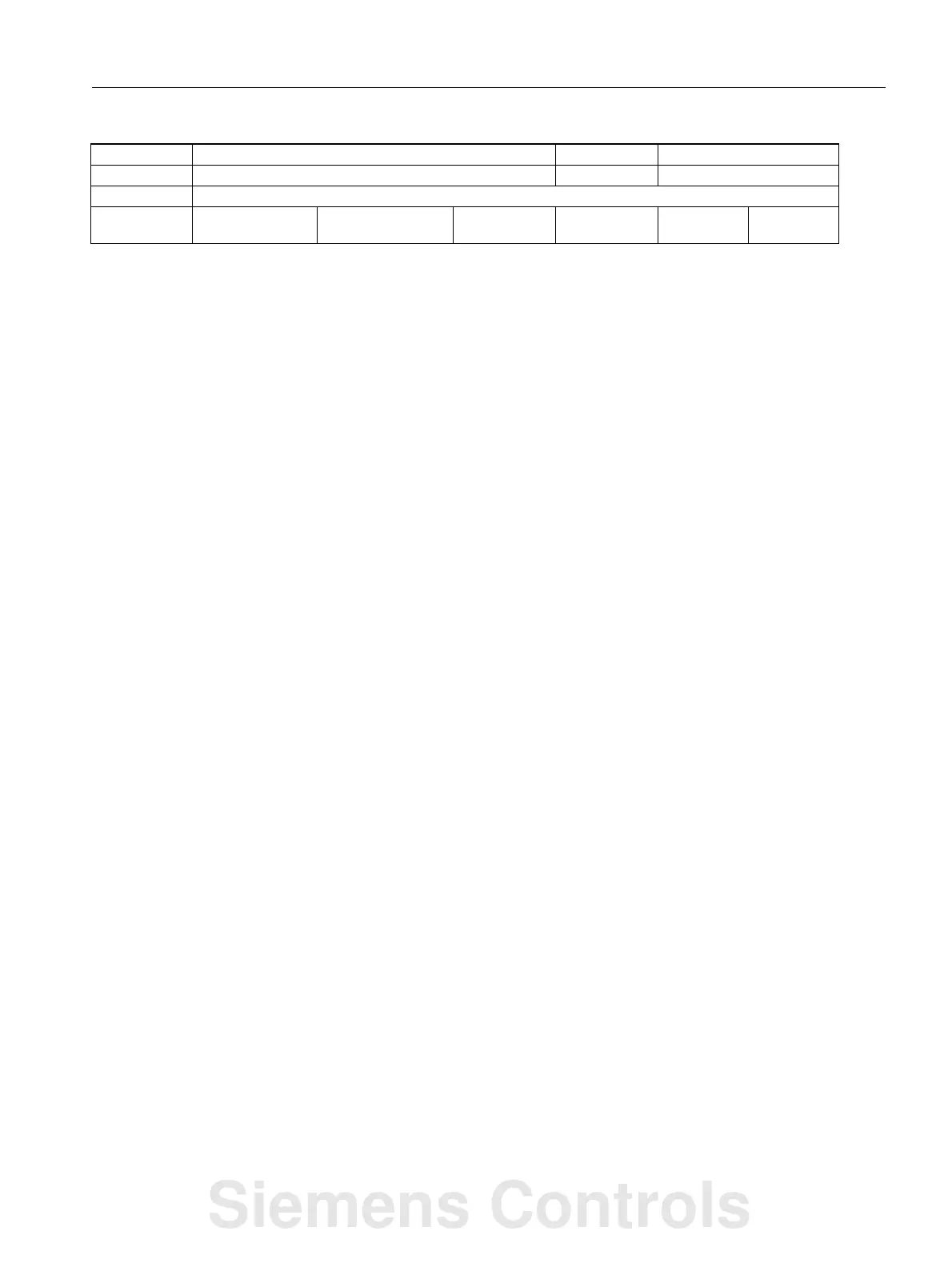

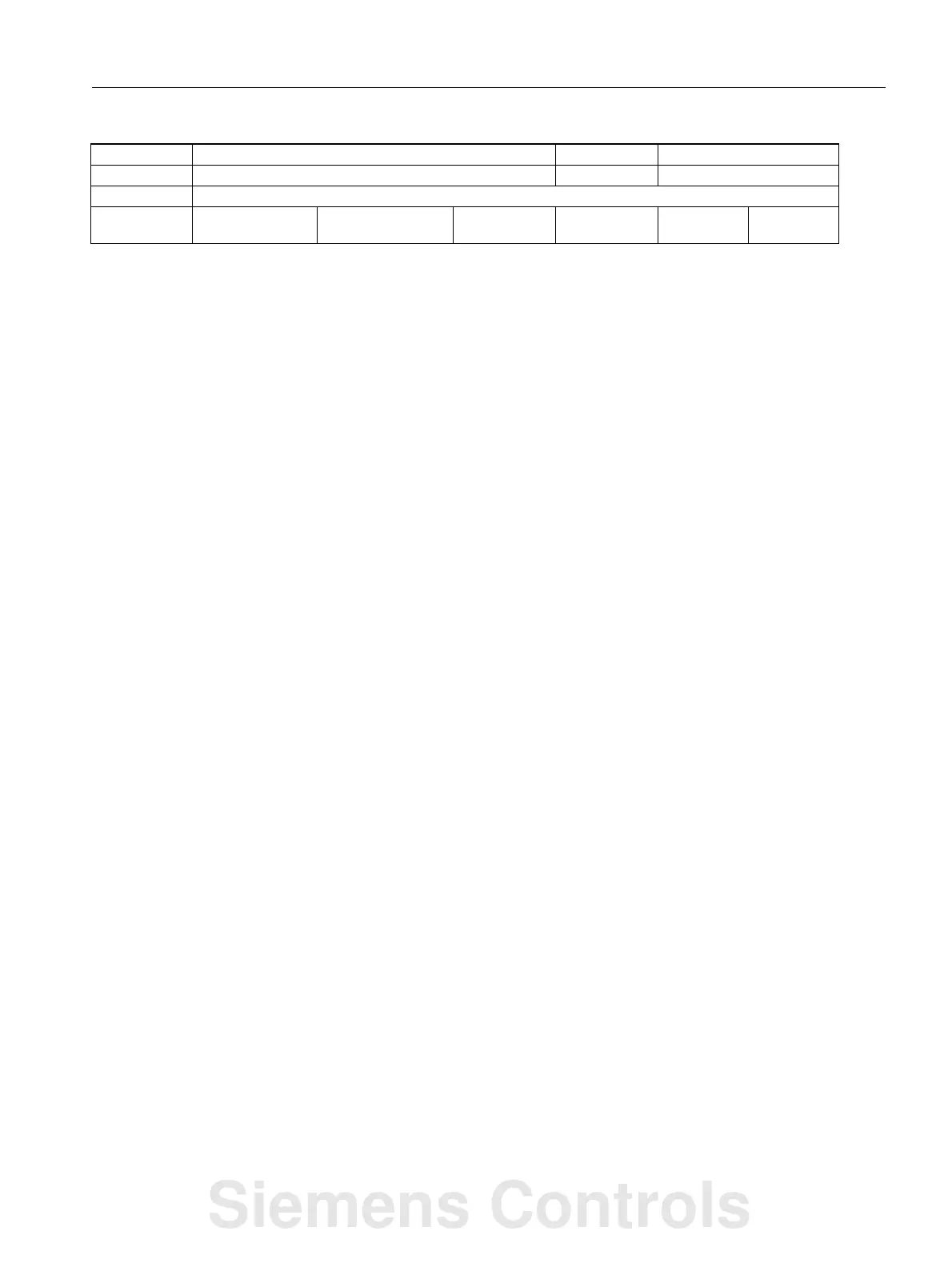

22562 TOOL_CHANGE_ERROR_MODE C09 W1

- Response to tool change errors DWORD PowerOn

-

- - 0x0, 0x0, 0x0, 0x0,

0x0, 0x0, 0x0, 0x0...

0 0x1FF 1/1

Siemens Controls

Loading...

Loading...