Detailed descriptions of interface signals

4.8 Axis / spindle-specific signals

Parameter Manual

402

Operating Instructions, 08/2013, 6FC5397-8EP40-0BA0

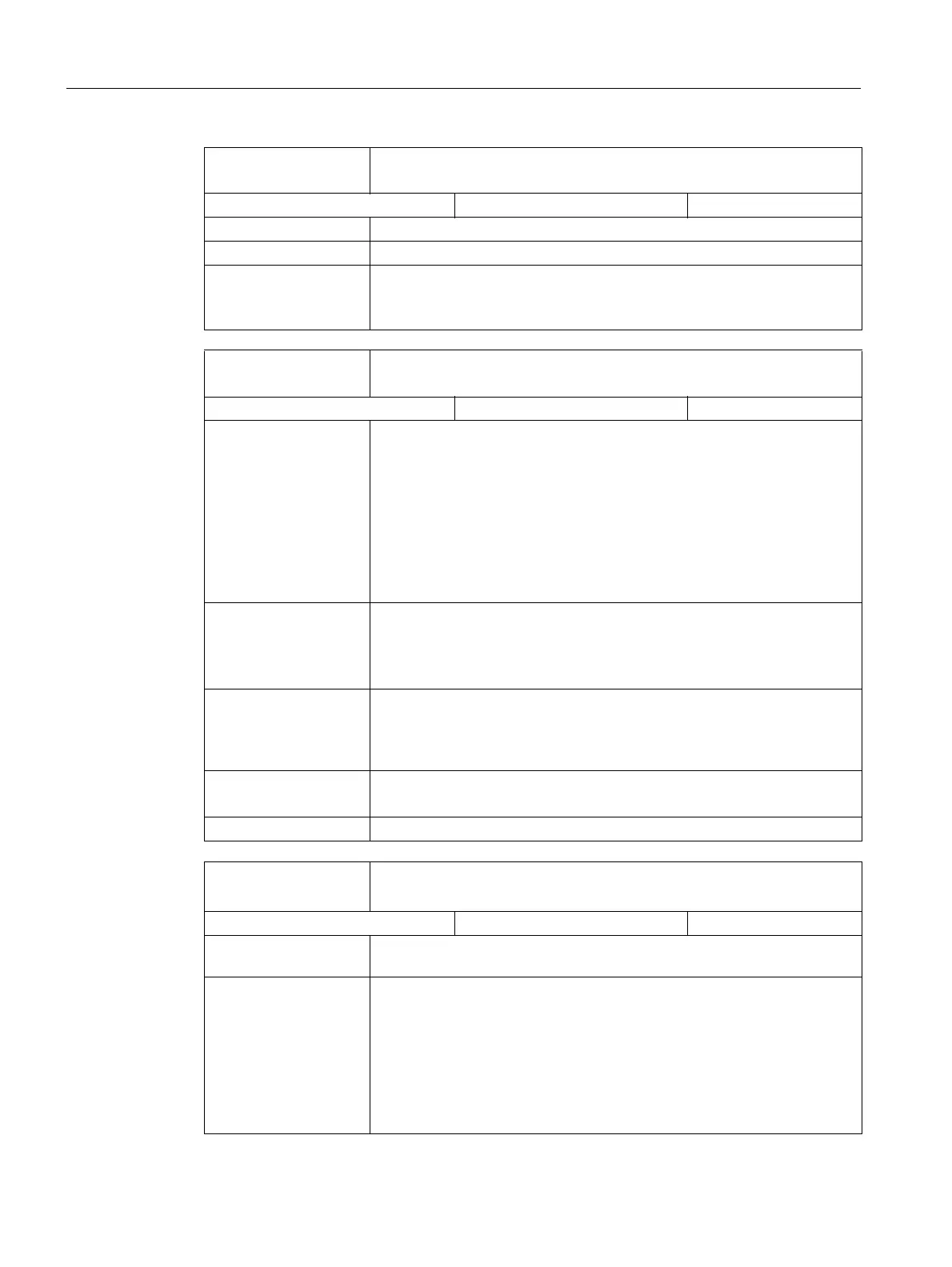

DB390x

DBX1.2

Axis ready

Signal(s) from axis / spindle (NCK → PLC)

Edge evaluation: No Signal(s) updated:

Meaning The signal is fed to the PPU, to which the axis is physically connected.

Signal state 1 Axis is ready.

Signal state 0 Axis is not ready.

This status is set if the channel, the mode group or the NCK have generated

the alarm "Not ready".

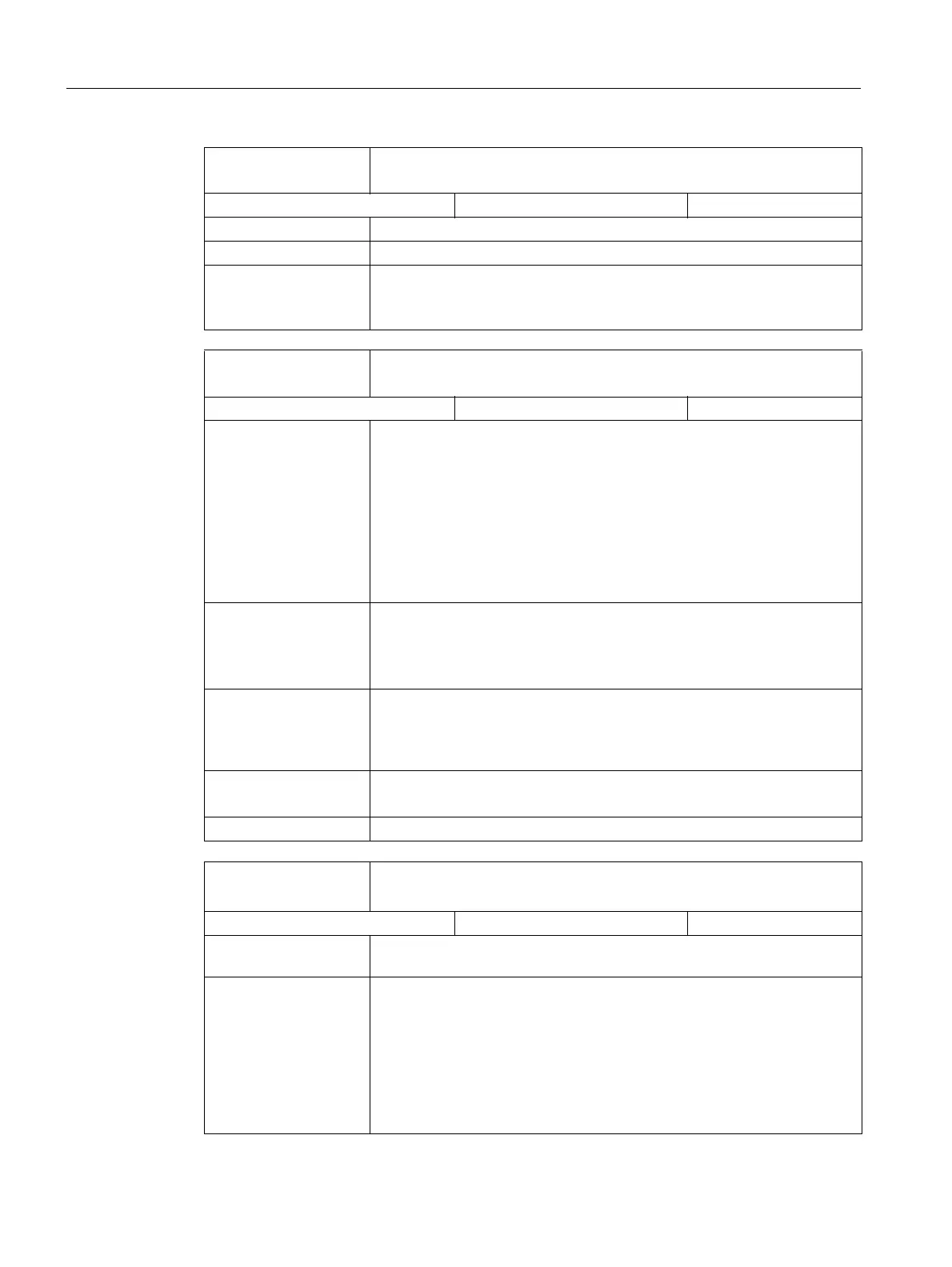

DB390x

DBX1.3

Follow-up mode active

Signal(s) from axis / spindle (NCK → PLC)

Edge evaluation: No Signal(s) updated: Cyclic

Signal state 1 The control signals that the follow-up mode for the axis / spindle is active.

Prerequisites for this are:

• The controller enable for the drive has been withdrawn (either by the

PLC with "controller enable " = 0 signal or inside the control for faults).

• Follow-up operation is selected (either by the PLC with IS "follow-up

operation" = 1 signal or in the control, e.g. when withdrawing the

controller enable from an axis that is moving)

The position setpoint continually tracks the actual value while the follow-up

mode is active. The standstill and clamping monitoring are not active.

Signal state 0 The control signals that follow-up mode for the axis / spindle is not active,

i.e. the above mentioned prerequisites are not fulfilled.

Zero speed and clamping monitoring are active.

In the "Hold" state, the IS "Follow-up mode active" has a 0 signal.

Special cases, errors, ... Notice:

A delete distance-to-go is triggered internally in the control at the transition

from "Follow up" to "Hold" (IS "Follow-up mode" = 0) or in the closed-loop

control mode (IS "Controller enable" = 1).

corresponding to ... DB380x DBX2.1 (controller enable)

DB380x DBX1.4 (controller enable!)

Note for the reader Function Manual, Special Functions; M3/T3

DB390x

DBX1.4

Axis / spindle stationary (n < n

min

)

Signal(s) from axis / spindle (NCK → PLC)

Edge evaluation: No Signal(s) updated: Cyclic

Signal state 1 The actual velocity of the axis or the actual speed of the spindle lies under

the limit defined using the MD36060.

Signal state 0 The actual velocity of the axis or the actual spindle speed is greater than the

value specified in MD36060 (standstill / zero speed range).

If a travel command is present, e.g. for a spindle, then the signal is always =

0 - even if the actual speed lies below that specified in MD36060.

If the IS "Axis / spindle stationary" is signaled and there is no closed-loop

position control active for the spindle, then at the operator interface, an

actual speed of zero is displayed and with the system variable $AA_S[n]

zero is read.

Loading...

Loading...