04/96

Siemens AG 2001 All rights reserved 6FC5198–jAB40

1–187

SINUMERIK 840C / SIMODRIVE 611–D (DA)

b) In cyclic mode

For MSD:

S Pulse suppression, motor runs down

S SIMODRIVE_READY and DRIVE_READY are cancelled

S Power On fault

S Pulse and controller disable corresponds to STOP A with SINUMERIK Safety Integrated.

For FDD:

S Controllers are disabled. Motor is braked.

S SIMODRIVE_READY and DRIVE_READY are cancelled

S Power On fault

S Regenerative stop (corresponds to STOP B) with SINUMERIK Safety Integrated.

Response via MD 1612.0, can be configured as from SW 4

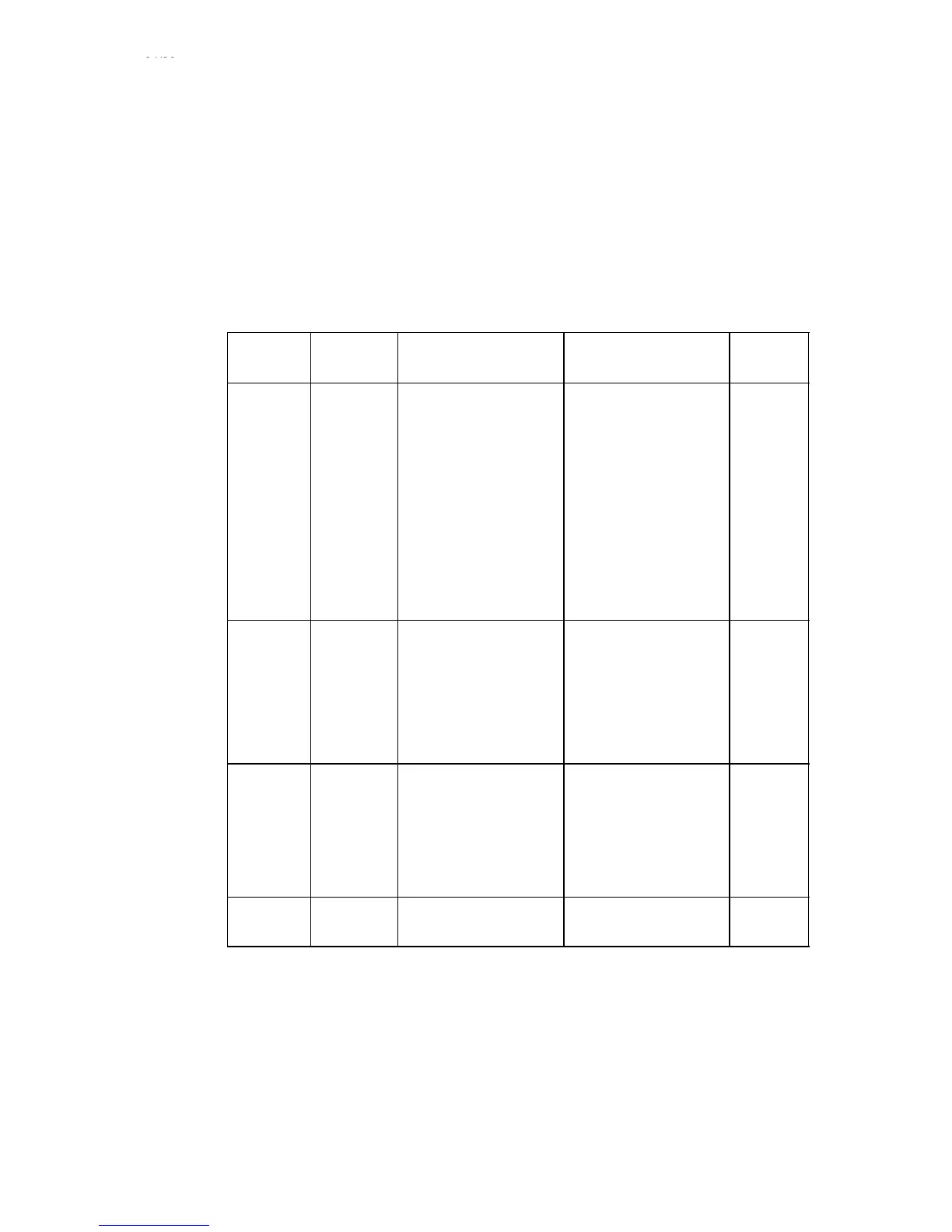

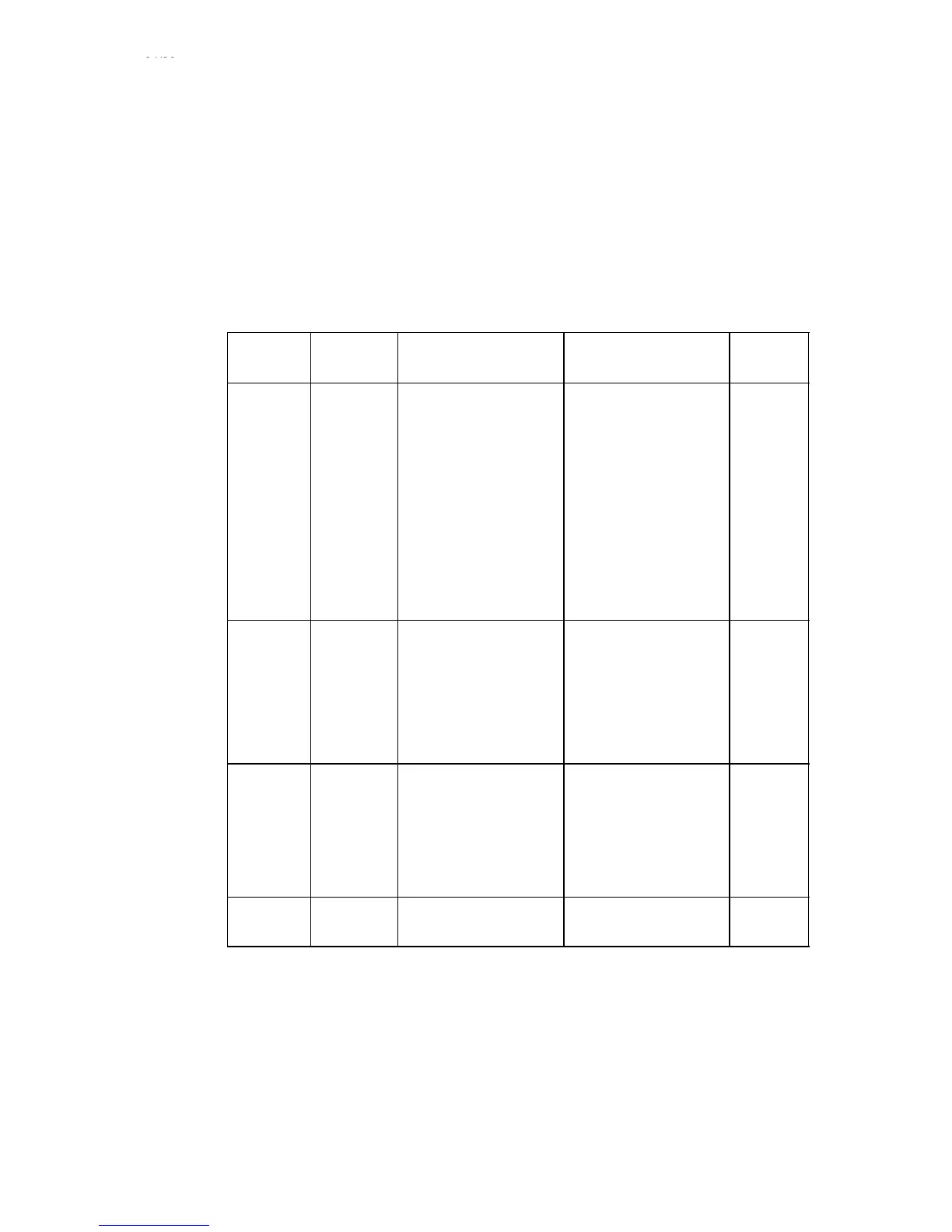

Error No.

F...

Additional

information

(xx = for diagno-

stic purposes)

Explanation Remedy Relevant for

F003 Time slice / xx

20=current con-

troller cycle (MD

1000)

10=speed con-

troller cycle (MD

1001)

8=position con-

troller cycle (NC

MD)

4=1 ms (perma-

nent)

2=4 ms (perma-

nent)

1=monitoring

cycle (MD 1102)

A0=start–up syn-

chronization

B0=background

computing time

40=SI monitoring

cycle (MD 1300)

The computation time of the drive

processor is no longer sufficient for

the selected functions in the given

clock pulse times. This error nor-

mally occurs only in conjunction

with start-up functions (FFT measu-

rement, step response).

SINUMERIK Safety Integrated:

Monitoring cycle too small.

During start-up with FFT or measu-

rement of the step response

– Switch off emergency retraction

– Switch off feedforward control

(MD 1004.0)

– Switch off min-max memory (MD

1650.0)

– Reduce number of DAC output

channels (max. 1 channel)

– Switch off variable signalling

function (MD1620.0)

– Switch off encoder phase error

compensation (MD1011.1)

– Select larger position controller

cycle for the NC.

– Increase the corresponding cycle

or the subordinate cycle (e.g.

current, speed or position control

cycle) or deselect functions which

are not required.

FDD / MSD

F004 xx / xx With controller enable, the NC must

update the sign-of-life in each posi-

tion controller cycle. If an error oc-

curs, there has been no sign-of-life

for at least two consecutive position

controller cycles. Causes: NC fai-

lure, communication failure via the

drive bus. Hardware fault on the

drive module or HW error on NC

CPU if error occurs sporadically at

intervals of several hours. A further

reason: ring programming with GI or

gantry axes.

Check plug-on connections, take

measures to eliminate noise (scree-

ning, check ground connections).

Replace NC hardware, replace

servo control module.

FDD / MSD

F005 xx / xx

1A: SZ <> 1 for

IZ=0

2A: SZ <> 1, 2, 3,

4, 5

2B: SZ IZ <> 0, 1

2C: SZ=3 for PO

parameterization

error

3A: SZ <> 1, 2, 3,

4, 5

3B: SZ IZ <> 0, 1

Ramping up of the drive modules is

broken down into 5 states (steps).

The states are provided in se-

quence by the NC and acknowled-

ged by the drive. If an error occurs,

an invalid setpoint state has been

detected in the drive. Causes:

Faults in communication via the

drive bus. Hardware fault on the

drive module, hardware fault on the

NC.

Check plug-on connections, take

measures to eliminate noise (scree-

ning, check ground connections).

Replace NC hardware, replace

servo control module.

FDD / MSD

F006 xx / xx The endless loop for processing

communication has been exited.

Presumably caused by a hardware

fault on the servo control module.

Replace servo control module. FDD / MSD

Effect

Explanation

1 Alarms

1.5.1 Alarm description

07/97

Loading...

Loading...