FADAL MACHINING CENTERS

62 INSTALLATION PROCEDURE MAN-0126_R1

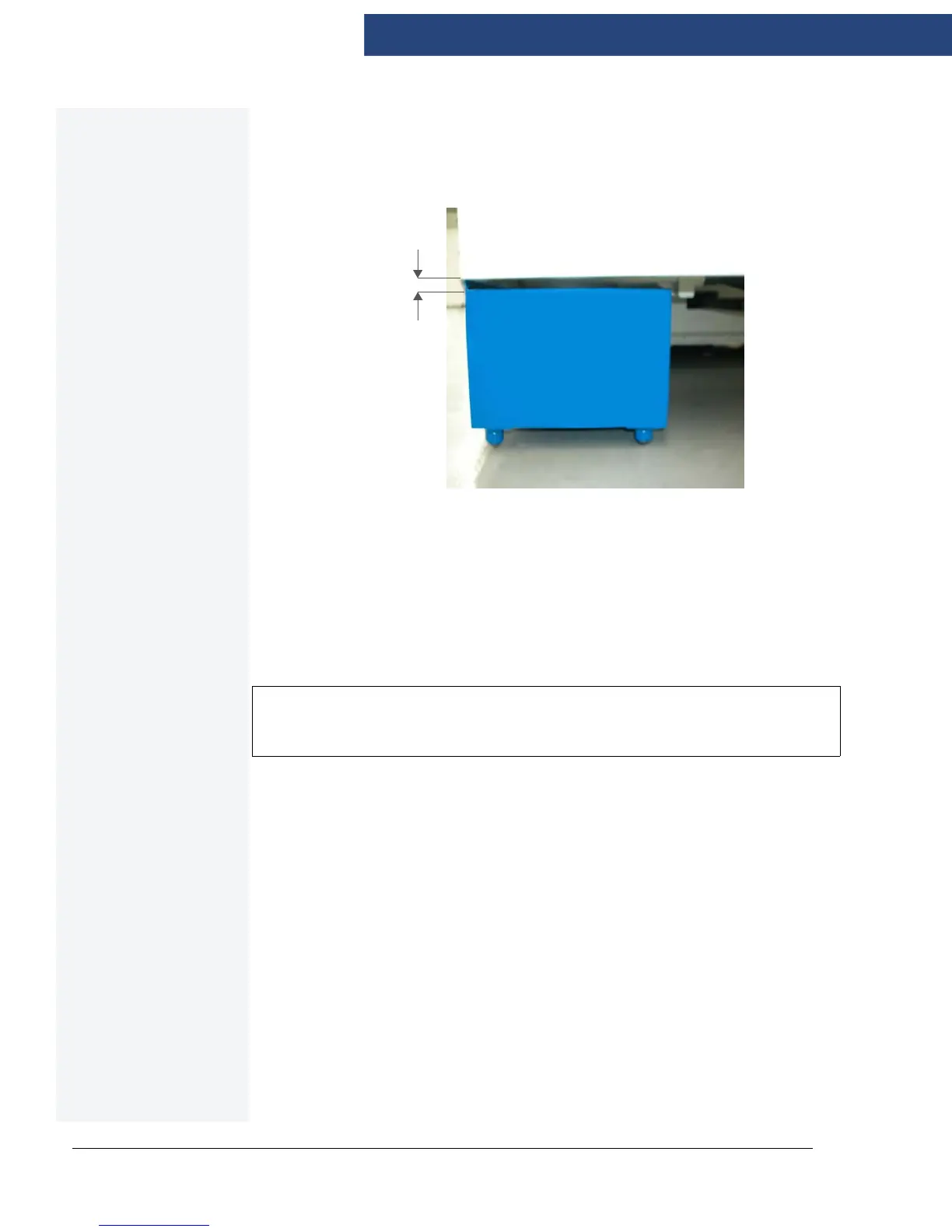

7. Adjust the machine height (during leveling and installation) to minimize the gap (or

overlap) between the coolant tank face and the machine sheet metal, (Figure 3-17:

Minimize Gap of Overlap).

Figure 3-17: Minimize Gap or Overlap

8. Coolant, wash down and flood pumps are connected per normal installation/setup.

9. A standard 55 gallon drum can be positioned underneath the conveyor discharge to

collect the chips.

3.10.2 CHIP

CONVEYOR POWER

AND CONTROLS

NOTE

The conveyor must be plugged into the provided outlet on the VMC which is dedicated for the chip

conveyor.

1. The control has 3 operating positions:

Forward - Controls the forward motion of the conveyor belt

Stop/Reset - Shuts off the conveyor

Reverse - Reverses direction of the conveyor belt (for clearing jams)

Gap

Loading...

Loading...