OCTOBER 2005 MACHINE MAINTENANCE 69

SIEMENS

MAINTENANCE MANUAL

WARNING!

Wear safety glasses!

If the fan is turning slowly or not at all, it may require cleaning or replacement. The fan

on the bottom of the junction box has a screen that requires periodic inspection and

removal for cleaning.

4.1.4 SPINDLE &

BALLSCREW COOL-

ING SYSTEM

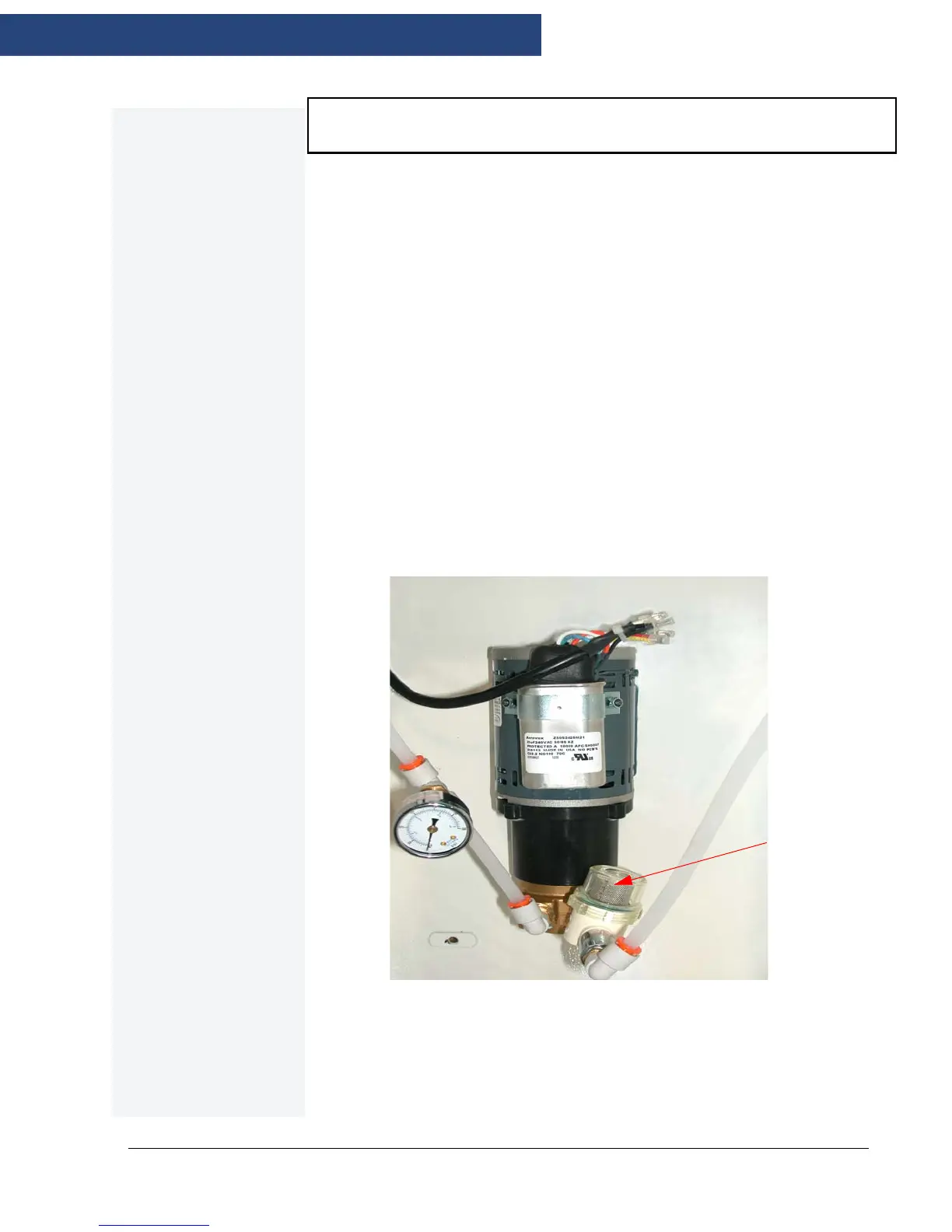

The spindle and ballscrew cooling system is made up of a motor pump assembly,

ambient-liquid temperature sensor assembly and a DP5P chiller. As long as there is

power to the machine the chiller pump is circulating DOWFROST™ through the

system. The ambient sensor is used to measure casting/air temperature and the liquid

sensor to measure Dowfrost temperature in the return line. When there is a one degree

temperature differential between the two sensors the chiller is then powered on.

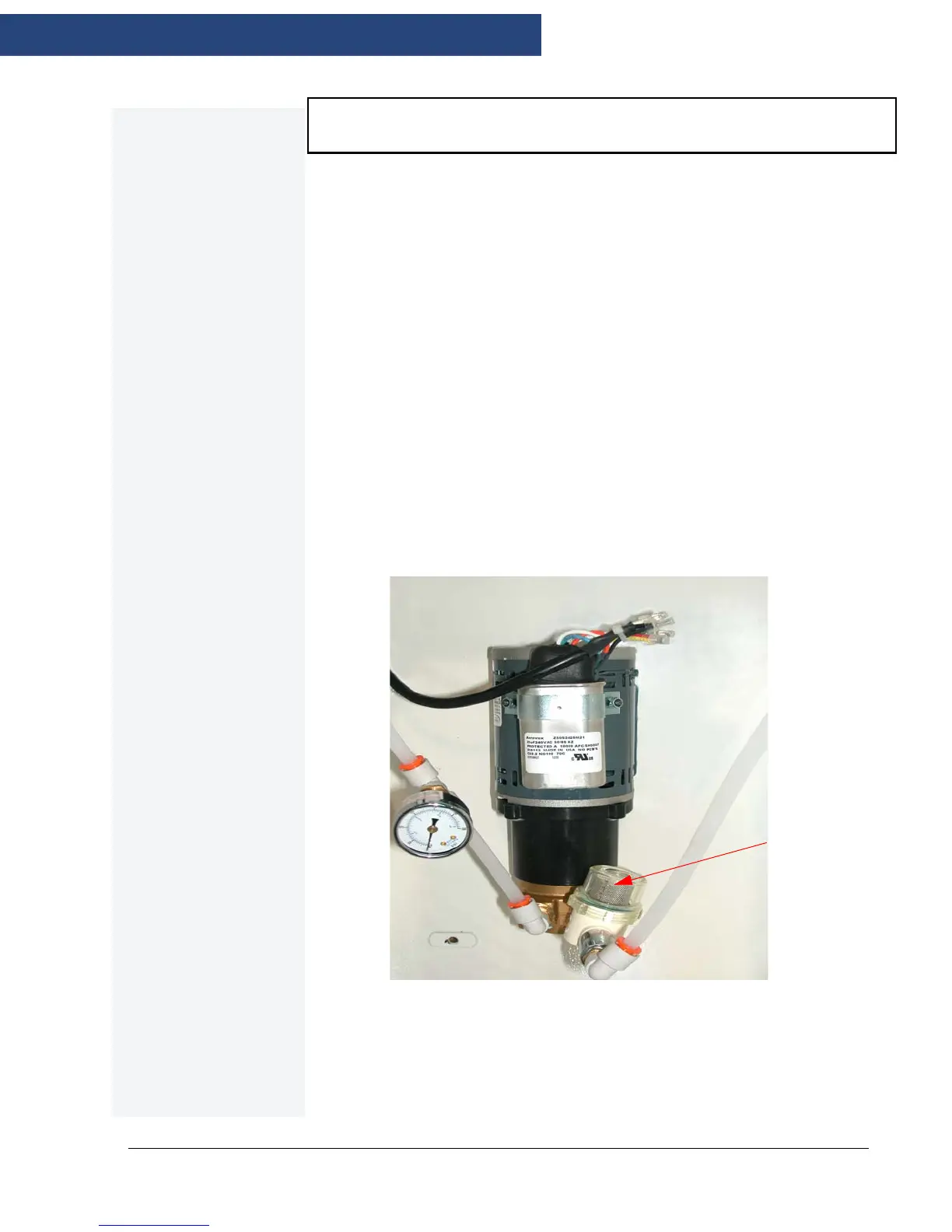

4.1.5 PUMP FILTER

There is a small filter and pressure gauge located on the pump head assembly. Normal

pressure is 3-5 pounds, cooled ball screws are 10 to 30 pounds. If the pressure gauge

shows a pressure above normal the filter should be inspected and cleaned.

Figure 4-1 Pump Filter

Filter

Loading...

Loading...