7 - 89

7 Transmission Repair

7D Hydro-Gear 0750 / 0800

33. Remove the motor thrust bearing assembly, swash-

plate kit and cradle bearings from the housing and

inspect for unusual wear or damage.

34. Remove the slot guide block from the displacement

control shaft.

35. Remove the bypass actuator from the housing.

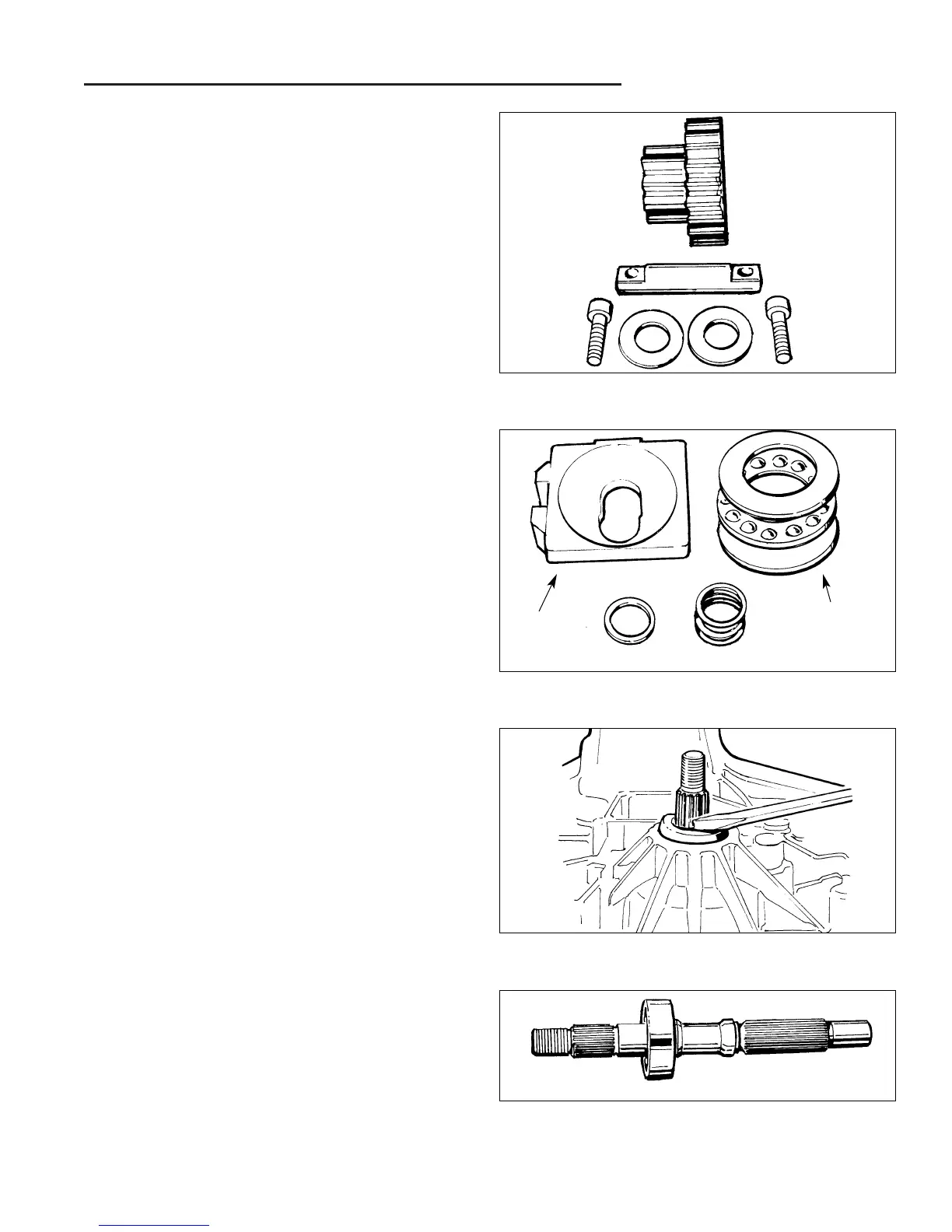

Figure D–23.Swashplate & Thrust Bearing Assembly

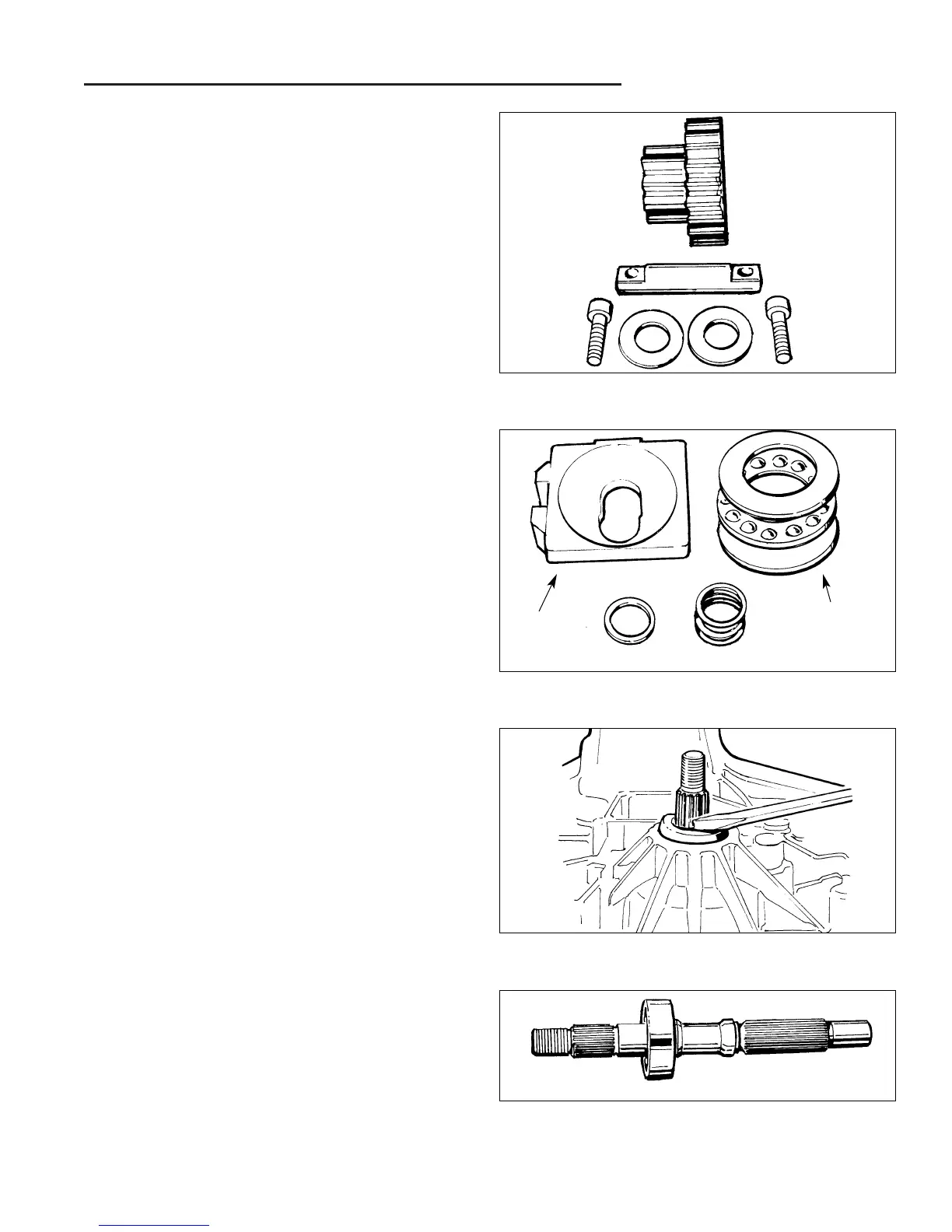

Figure D–24. Remove Input Shaft Seal

Figure D–25. Pump Input Shaft Assembly

Figure D–22. Jack Shaft/Pinion Gear Components

29. Inspect the jackshaft running surface for excessive

wear or damage. The jackshaft should be 0.4986” to

0.4996”.

30. Inspect the pinion gear bore for excessive wear or

damage. The bore should be 0.5014” to 0.5024”.

31. Inspect the pinion gear teeth for excessive wear or

damage.

32. If excessive wear or damage was found, the com-

plete assembly should be replaced.

36. Reposition the housing and remove the input shaft lip

seal from the housing bore. A hook type tool may be

used to pry the seal out. Care must be taken to avoid

damage to the housing bore, shaft sealing surface or

bearing. Once removed, the seal is not to be reused.

37. Remove the input shaft bearing retaining ring.

38. Remove the pump and input shaft assembly from the

transaxle housing.

39. Inspect the shaft and bearing for unusual wear or

damage.

40. Reposition the housing and remove the displacement

control shaft and lip seal.

41. Inspect the housing for damage.

Thrust

Bearing

Assm.

Guide

Block

Bypass Actuator

Loading...

Loading...