7 - 41

7 Transmission Repair

7C Tuff Torq K60

TUFF TORQ K60 HYDROSTATIC

TRANSAXLE

General

The Tuff Torq model K60 consists of an axial piston

design pump and motor. Both utilize spherical nosed pis-

tons rotating against angled swash plates. The motor dri-

ves a pinion shaft, which drives the final differential gear,

and rear axles.

The level of cleanliness maintained while repairing the

transaxle could affect its performance. Work in a clean

area. Before removing transaxle from tractor, steam

clean or pressure wash all debris from surrounding area.

After disassembly, wash all parts with clean solvent and

blow parts dry with compressed air.

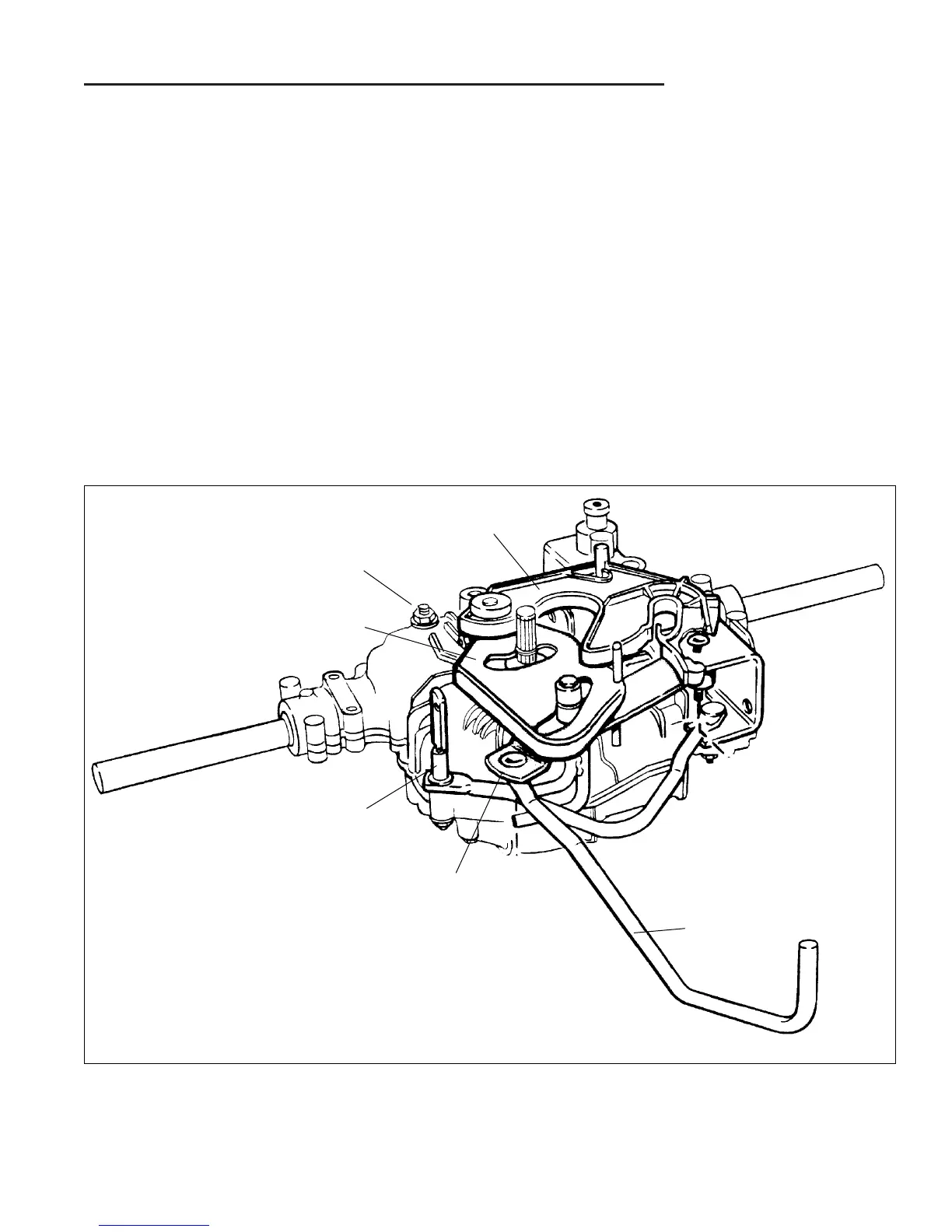

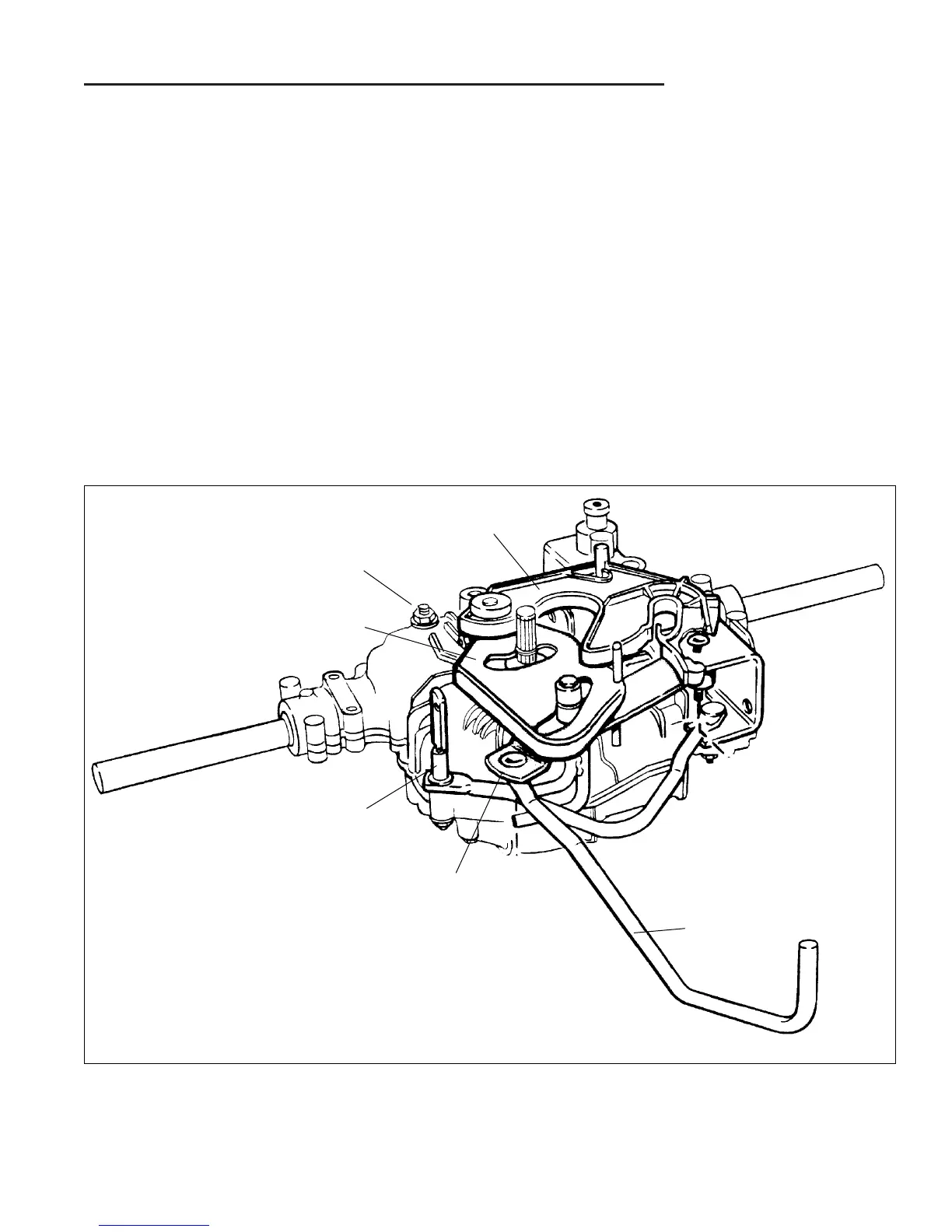

Figure C–1. Tuff Torq K60 Hydrostatic Transmission

Inspect all mating surfaces. Replace any damaged parts

that could cause internal leakage. Do not use emery

paper, files, or grinders on finished parts.

NOTE: Whenever a transaxle is disassembled, our ser-

vice policy is to replace all seals. Lubricate the new seals

with petroleum jelly before installation. Use only clean,

recommended fluid on the finished surfaces at reassem-

bly.

Shift Rod

Control Cam

Shift Lever

Return To Neutral Cam

Fulcrum Shaft

Torque Strap

Loading...

Loading...