7 - 39

7 Transmission Repair

7B Eaton 750 / 751

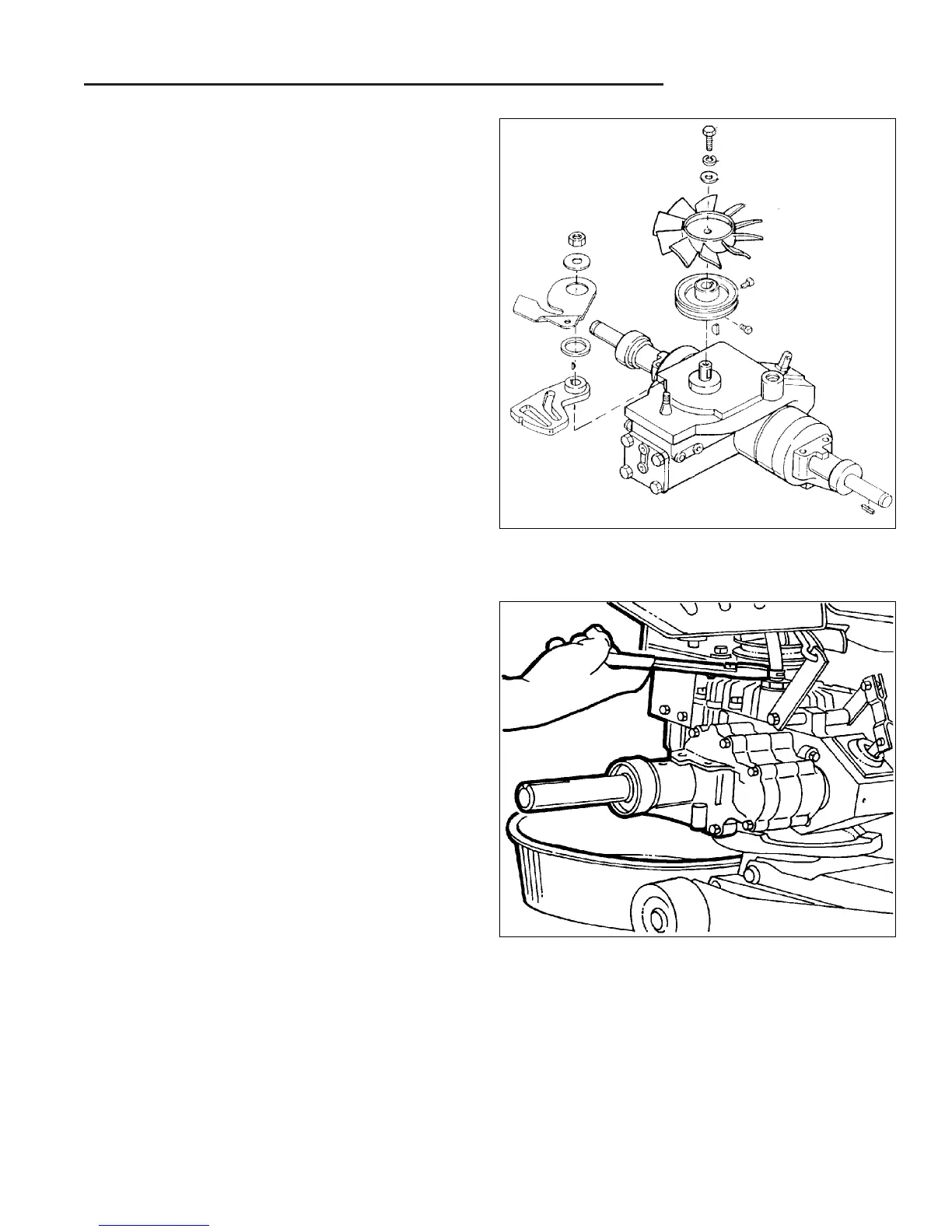

Installation

1. Install the brake lever bracket assembly and the front

transmission support assembly. Apply locktite to both

sets of capscrews and torque to 13-18 lb-ft.

2. Install the input pulley and key and secure with the

two setscrews.

3. Install the cooling fan with locktite on the capscrew.

4. Install the hydro cam and key over the tapered con-

trol shaft. Install the cam spacer, neutral return cam,

flat washer and nut. Torque the nut to 15-20 lb-ft.

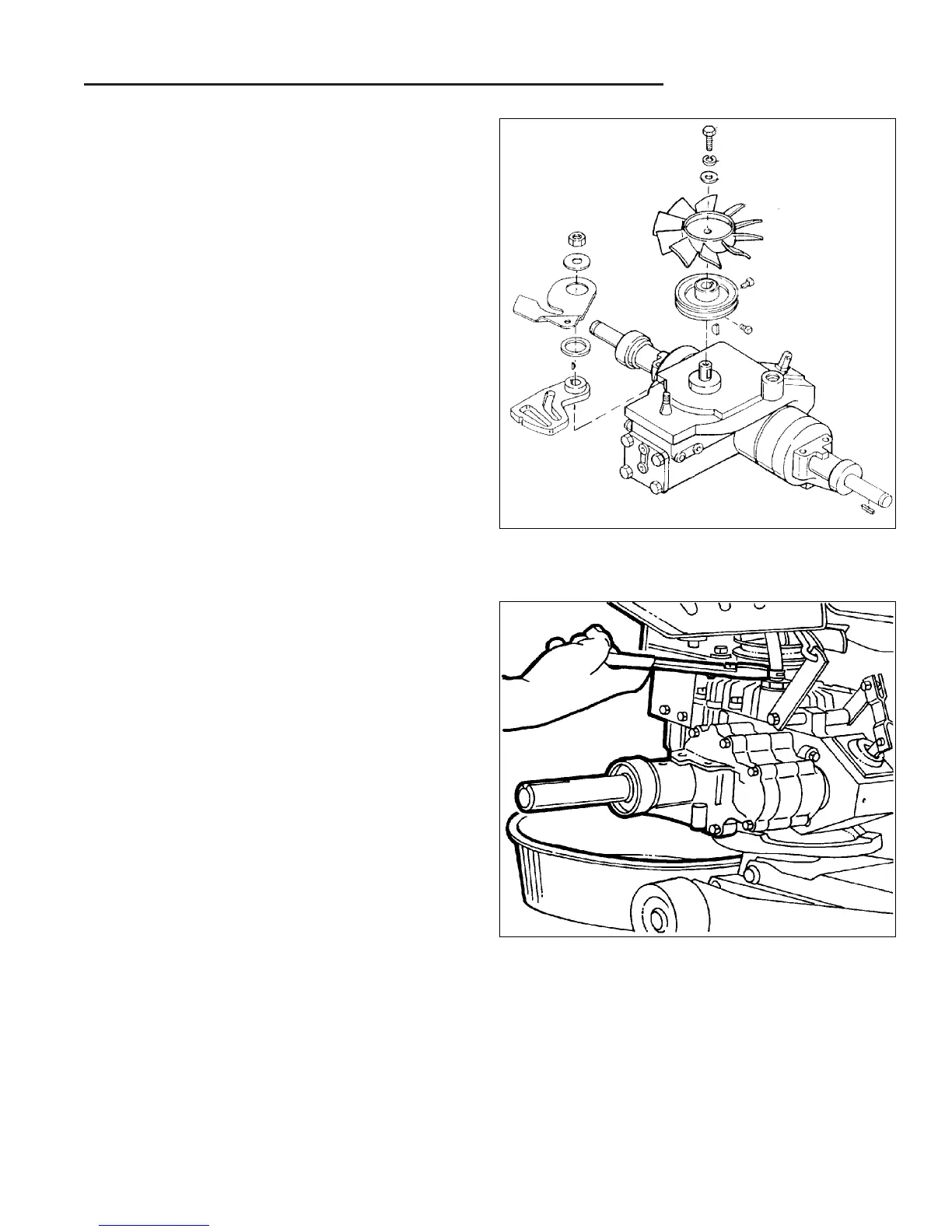

Note: At this time the transaxle should be filled with SAE

10W-30 weight motor oil through the return port hole.

Cover the opening until the hose is installed. Capacity is

69 oz.

5. Place the transaxle on a floor jack and raise just high

enough into the frame to install the following:

• Oil return hose to fitting on top of transaxle

• Brake rod to brake lever

• Route drive belt through blades of hydro fan and

onto input pulley.

6. Raise the transmission fully into the frame. Install and

tighten the axle mounting bolts to 23-27 lb-ft.. Secure

the front transmission support and torque to 13-18 ft

lb.

Figure B–102 Install External Transaxle Components

Figure B–103 Raise Transaxle Into Tractor

Loading...

Loading...