7

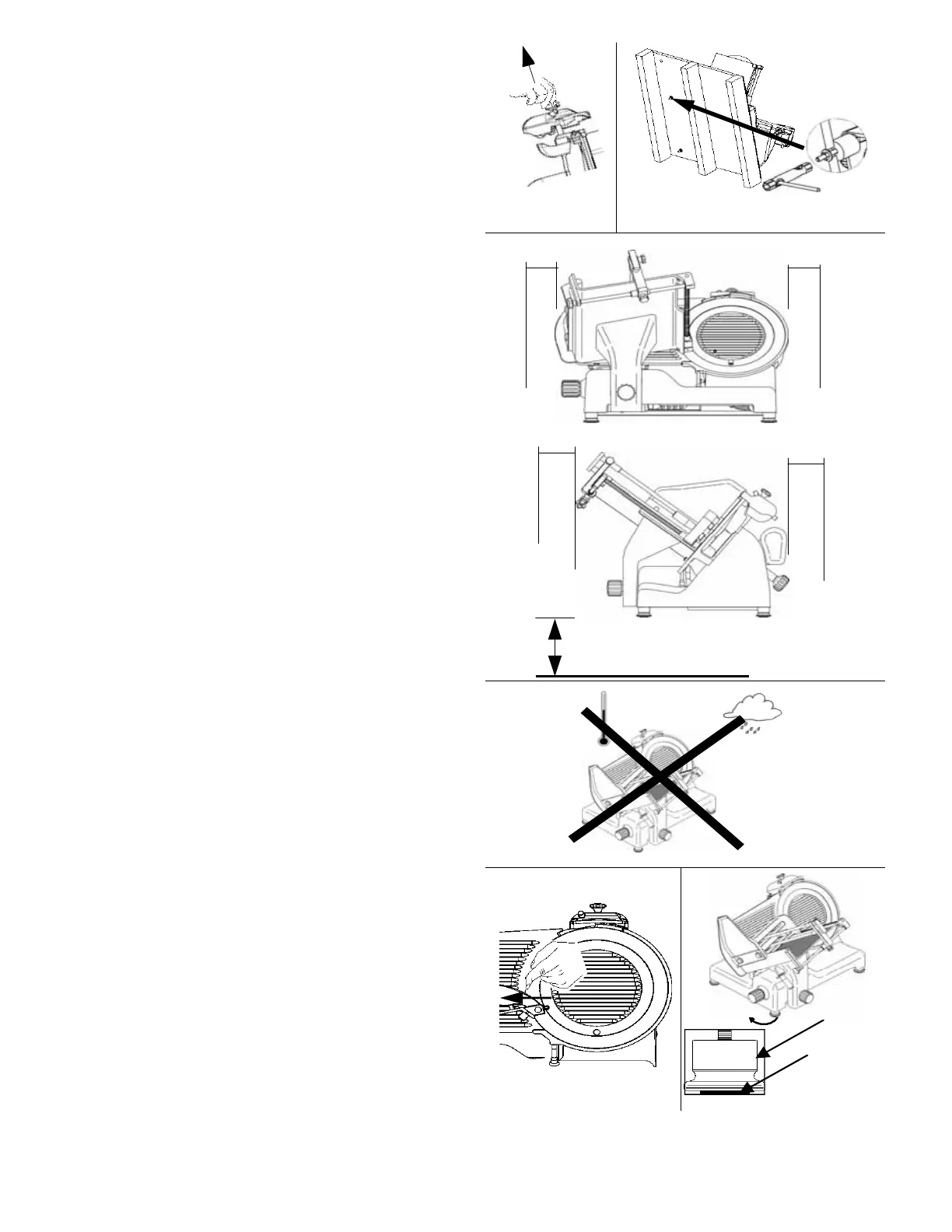

2.2 - POSITIONING

Position the pallet, with the slicer, on a flat

s

urface and remove (a) the cap from the slicer

(Fig. n°12).

Turn the machine on its side (Fig. n°13) and

utilising the correct wrench provided

uns

crew the 4 nuts which secure the slicer to

the pallet. Remove the 4 washers and unscrew

the 4 fastening tie rods on the wooden pallet.

Remove the pallet and fasten the 4 feet provided

to the slicer. Finally, replace cap in its

original

position.

P

osition the slicer in its final operating

location .

The dimensions indic

ated in Tab. 1-2-3 ( which

v

ary depending on model) must always be

c

onsidered and taken into account for when

deciding on the final location of the slicer.

Slicer location must be sufficiently wide

enough to accommodate the slicer, level, dry,

smooth, robust, stable and at a height of

approximately 80 cm from the ground and at

least 20 cm from walls, objects, shelves, etc.

(Fig. n°14) to allow for sufficient room to

operate the slicer respecting and safeguarding

operator safety.

Furthermore, the machine must be located in

an environment with a maximum humidity of

75%, non-saline and with a temperature

ranging between +5°C and +35°C; and in any

event in environments which conform to the above

s

pecifications .

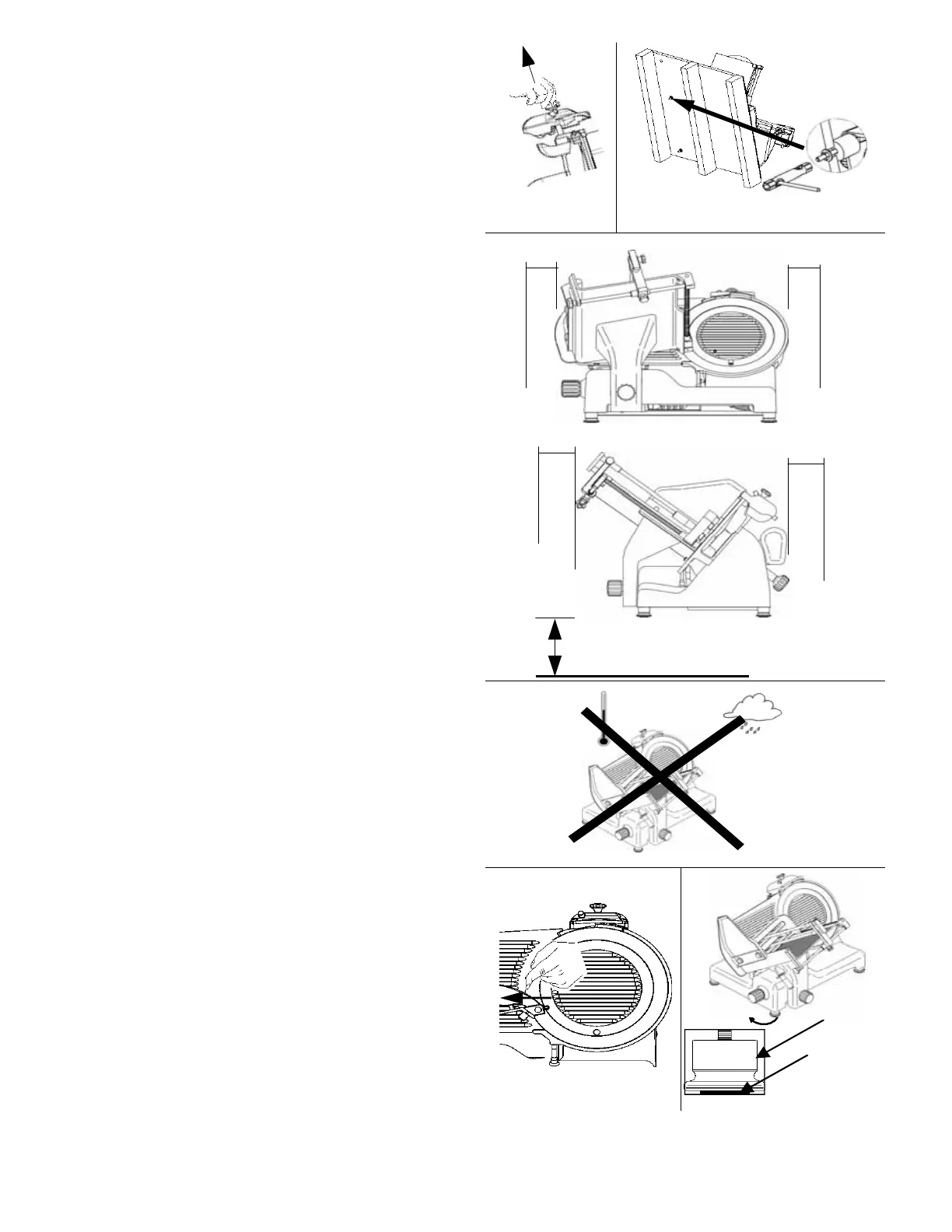

Make sure the graduated hand grip is in position

“0”.

Check alignment of the blade-

thickness gauge by

running a finger (Fig. n°16) from

the blade

towards the thickness gauge (never in the

opposite direction). Unscrew the feet on the

operator’s side until the slicer is correctly aligned

and level. (Fig. n°17).

a

~ 80cm

2

0cm

Fig. n°12 Fig. n°13

Fig. n°14

Fig. n°15

Fig. n°16 Fig. n°17

2

0cm

2

0cm

2

0cm

1

2

Loading...

Loading...