8

2.3 - ELECTRICAL CONNECTION

Check that the specifications prov

ided in the

rating plate -serial number (Fig. n°18) and in the

consignment and delivery documents,

correspond; if not contact the supplier immediately.

Check power supply cable and slicer earthing .

2.3.1 - Slicer with single-phase motor

The slicer is fitted with a power supply c

able having a cross section of 3x1mm²; approximate length

1.5m and a “SHUKO” plug. Connect the 230 V - 50 Hz slicer, interposing a 10 A ΔI= 0.03A

thermomagnetic differential switch.

2.3.2 - Slicer with 400 V. three-phase motor

The slicer is fitted with a power supply cable having a cross section area of 5x1mm², approximate

length 1.5m and a red 15A 3F + T CEI plug. Connect the slicer to the 400 V - 50Hz three-phase

supply mains, interposing a 10 A ΔI= 0.03A thermomagnetic differential switch.

2.3.3 - Slicer with 230 V. three-phase motor

The slicer is fitted with a power supply cable having a cross section area of 5x1mm², approximate

length 1.5m and a blue 15A 3F + T CEI plug. Connect the slicer to the 230 V - 50Hz three-phase

supply mains, interposing a 10 A ΔI= 0.03A thermomagnetic differential switch.

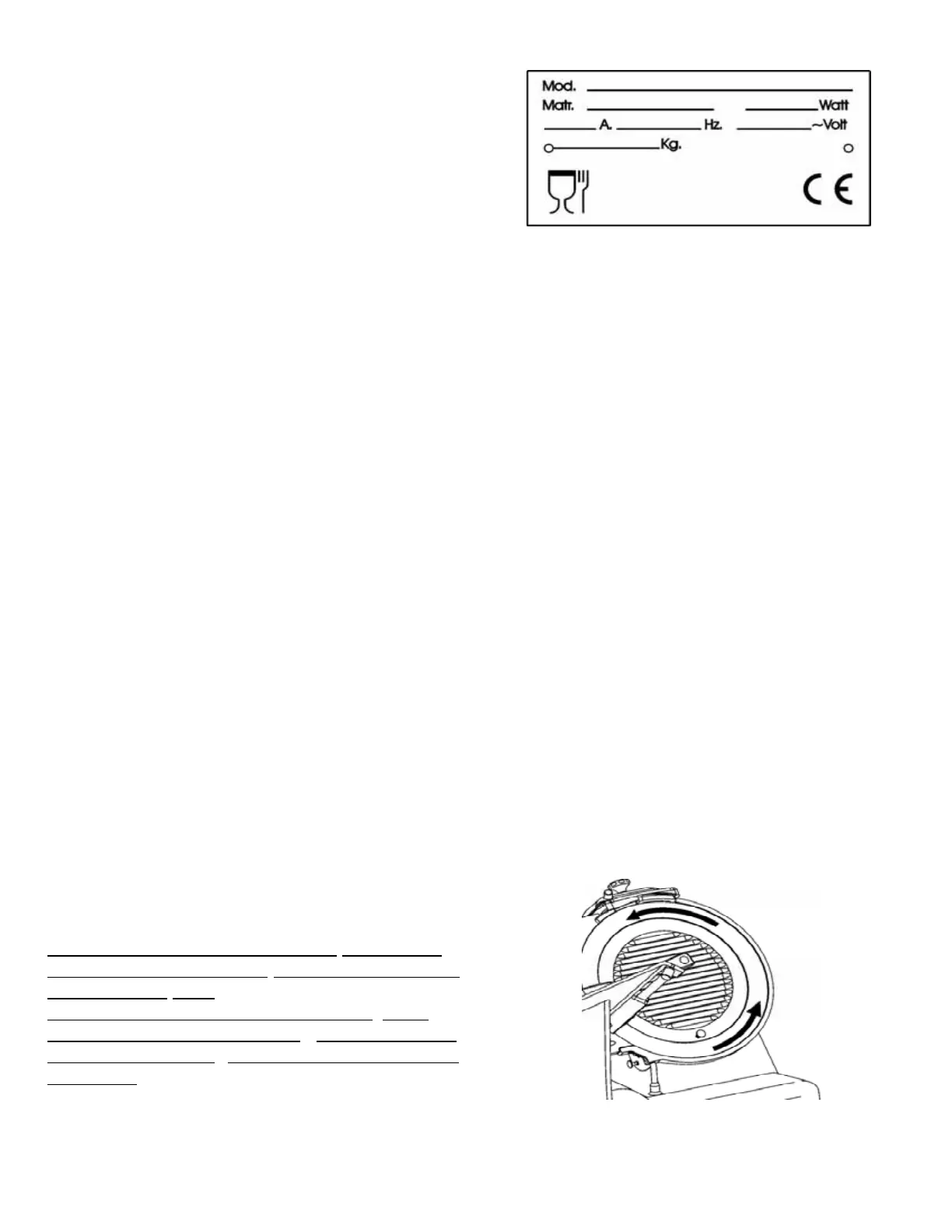

Check blade rotation is anti-clockwise looking at the slicer from bladeguard side. If not proceed as in

2.3.4 .

2.3.4 - Blade rotation direction

To check direction of blade rotation pr

ess the “I”

pushbutton (ON), and then immediately press the

“0” pushbutton OFF.

Blade rotation must be anti-clockwise when

looking at the slicer from bladeguard side

(Fig. n°19). In the event rotation is incorrect ,

invert (Fig.

Fig. n°18

Fig. n°19

Loading...

Loading...