Maintenance

8-3

aluminum sheet of the X-ray output, press the exposure hand switch level 1, make

sure the filament at the X-ray output is turned on normally, and then release the

hand switch.

【Caution】: Before exposure, the operator should make sure that the

shielded room is closed.

b) Use the hand switch for exposure. After the exposure is over, check the measured

kV value of the X-ray quality tester. If the measured kV value is (100 ± 5) kV, the

test is passed. If the kV value is out of range, fine-tune RP3 on the SYS board and

perform the exposure again till the kV value is within the range. Meanwhile, the kV

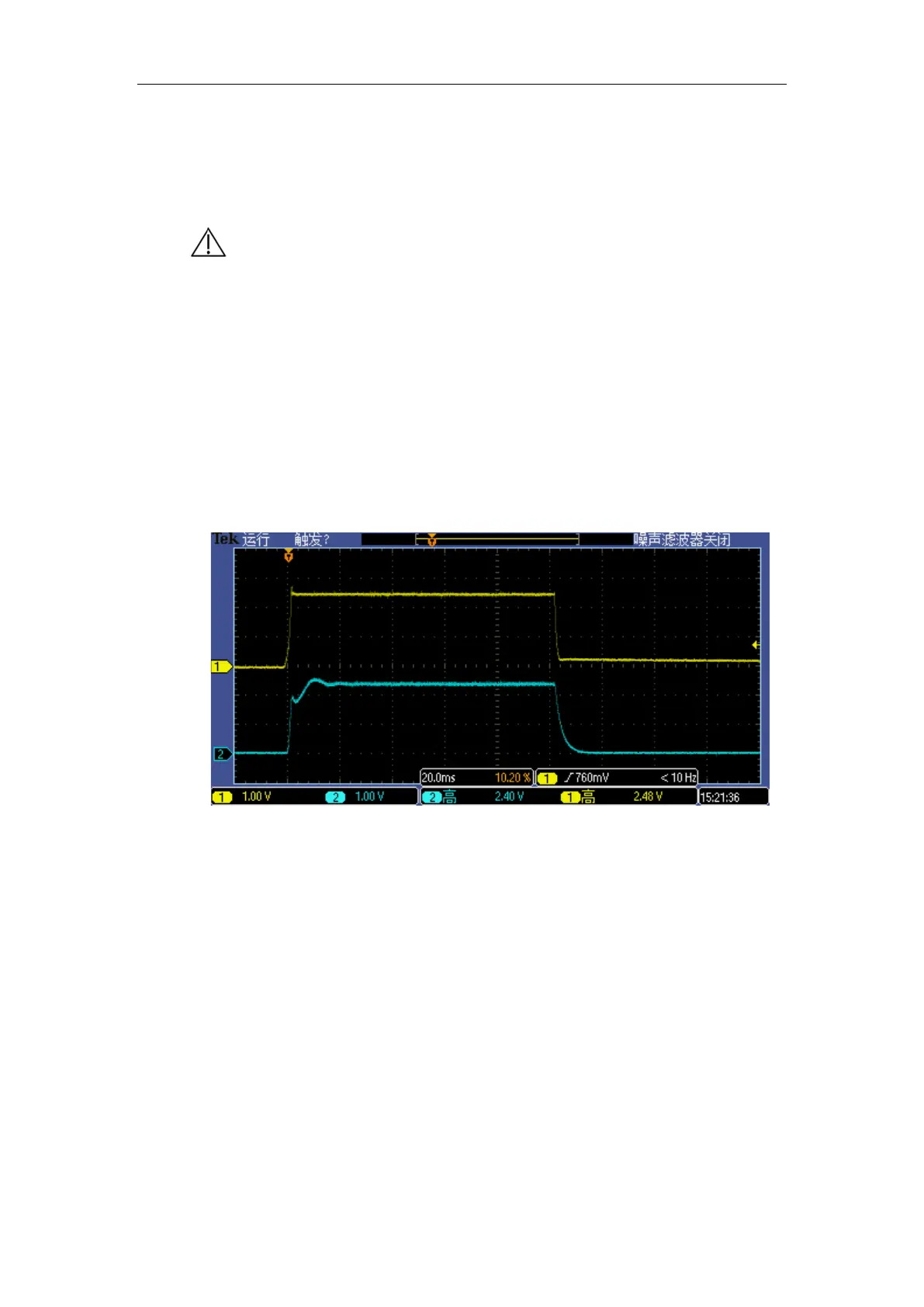

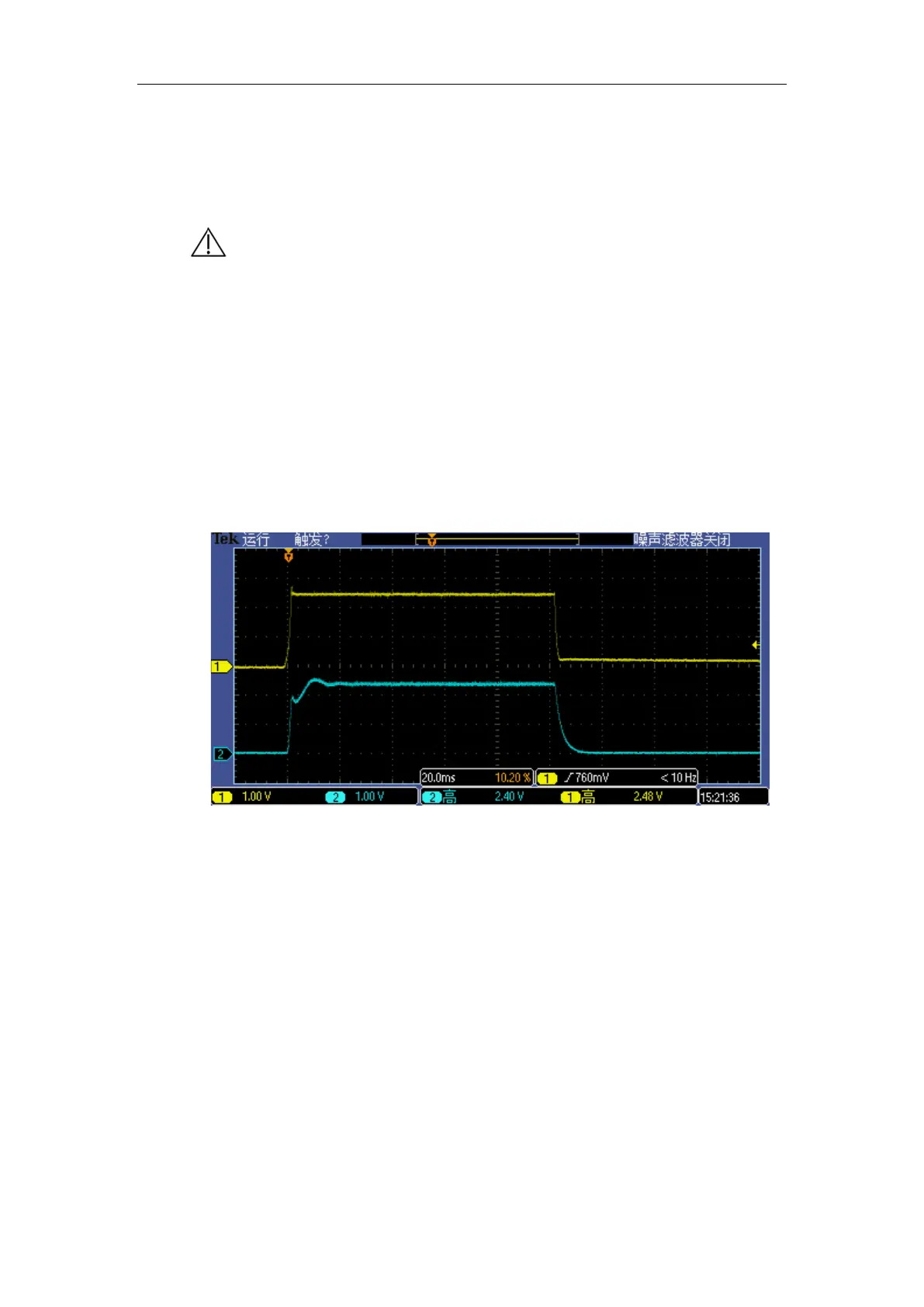

and mA output waveforms shall have no glitches and abnormalities. The proper kV

waveform is as shown Fig.8-1 below.

Fig. 8-1

c) Check the kV and mA feedback values on the oscilloscope. The kV feedback

value measured from the oscilloscope shall be (2.5±0.1) VDC, the mA feedback

value shall be (2.4±0.1) VDC, and the kV waveform duration is (100±5) ms.

d) Set the loading conditions of the control panel to 125kV ,25mA,2.5mAs. Under this

exposure condition, repeat the exposure operation multiple times. If the KV value

monitored by the X-ray quality tester is always maintained within the (125±5) kV

range, and the kV feedback monitoring value on the oscilloscope is (3.125±0.1)V,

the kV is passed.

4) X-ray tube current calibration

Loading...

Loading...