SJ3215, SJ3219, SJ3220, SJ3226, SJ4726, SJ4732, SJ4740 216380ACA

41

Visual and daily maintenance inspections Section 4 – Inspections Before Operation

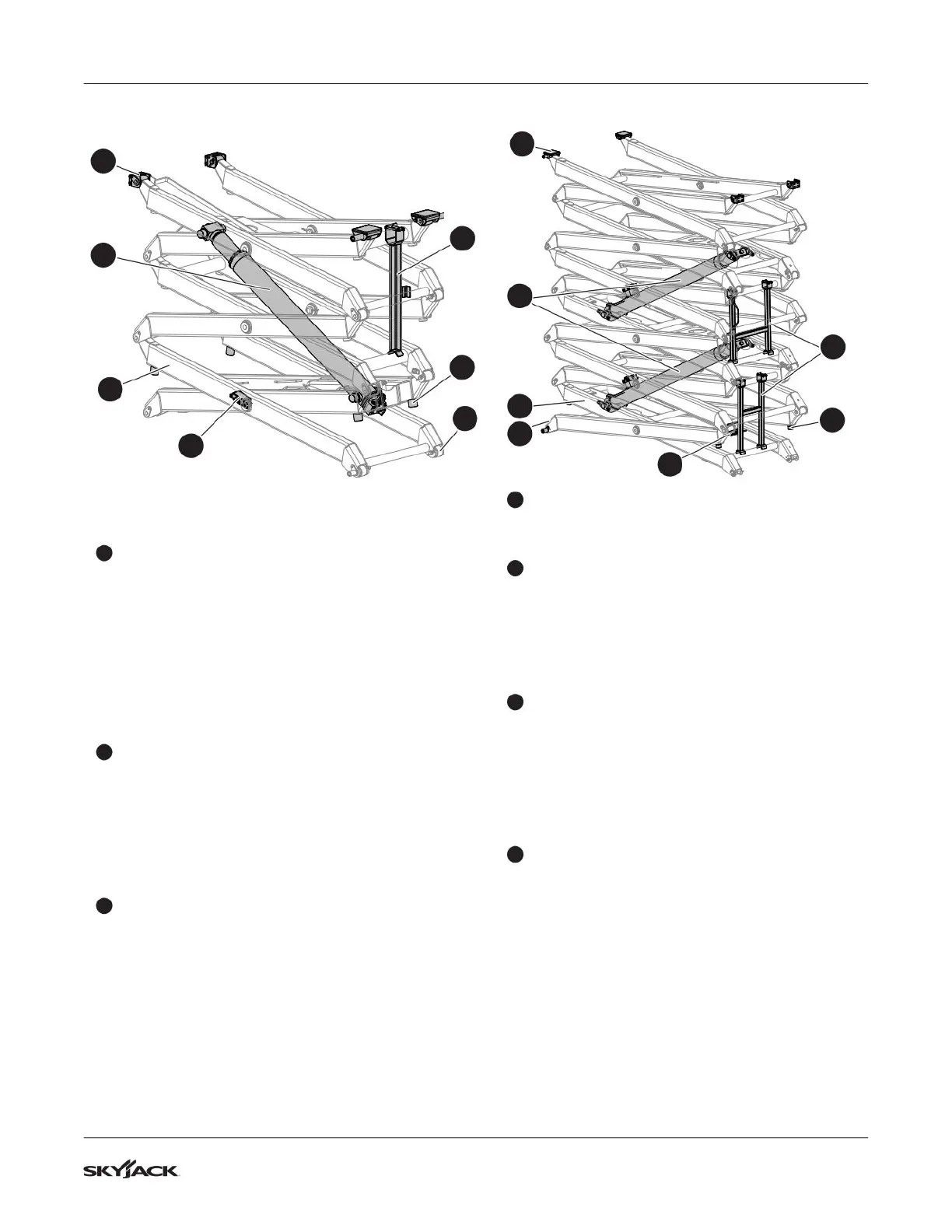

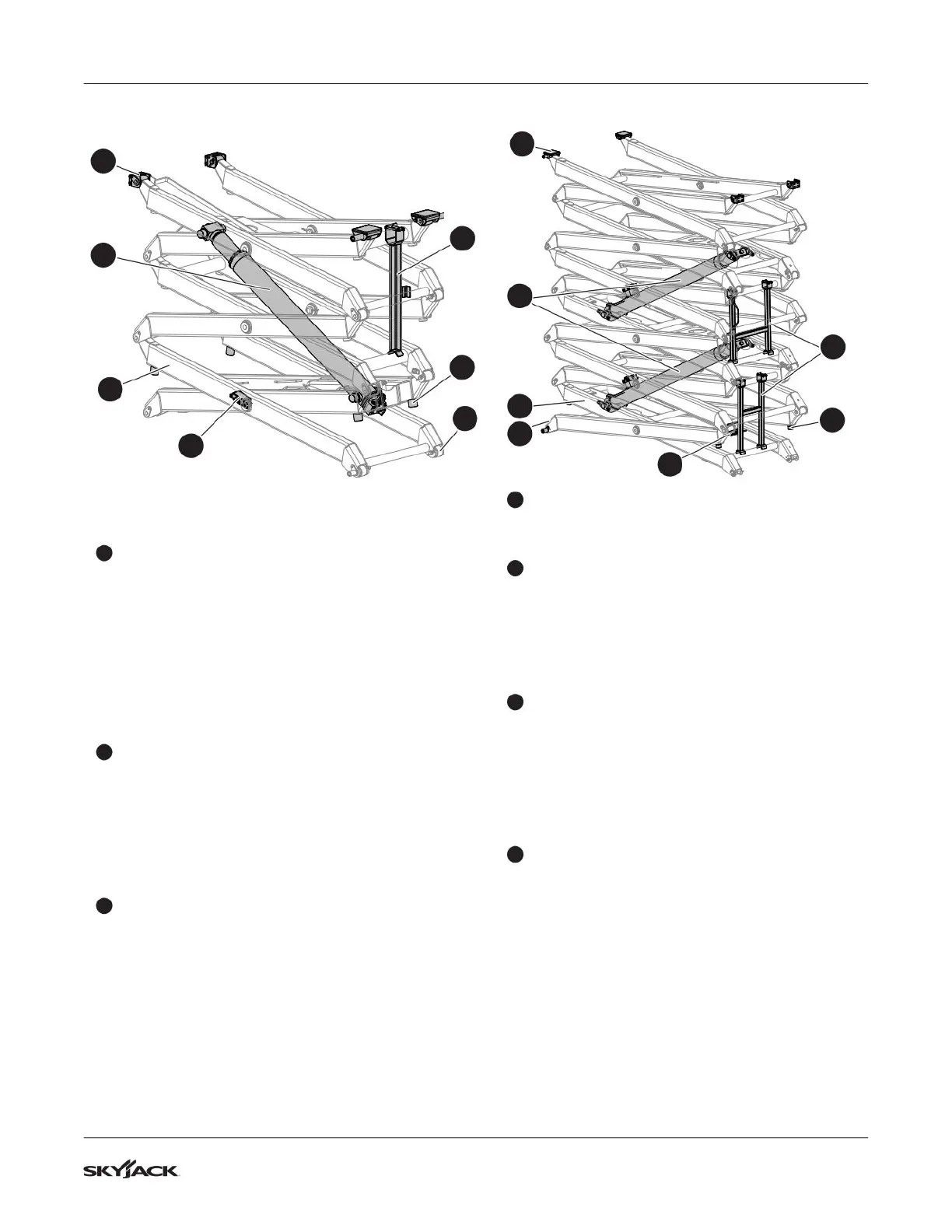

4.2-11 Lift mechanism

Do the inspection that follows in sequence:

1

Sliders

▪

Make sure that the sliders on the left and right

side of the MEWP are correctly attached.

▪

Make sure there is no visible damage.

▪

Make sure there is no dirt or blockages in the

slider paths.

1. Raise the platform (refer to Section 5.2) and

deploy the maintenance support(s) (refer to

Section 6.8-1).

2

Maintenance support(s)

▪

Make sure that the maintenance support(s)

are correctly attached and show no visible

damage.

NOTE

SJ4740 model has two maintenance supports. All

other models only have one maintenance support.

3

Scissor assembly

▪

Make sure that the scissor assembly shows

no signs of visible damage, deformation, or

cracks in the weldments.

▪

Make sure all the pins and fasteners are

correctly installed.

▪

Make sure that the cables and wires have the

correct routing, and show no signs of wear

and/or physical damage.

4

Scissor bumpers

▪

Make sure that the bumpers are correctly

attached and have no visible damage.

5

Rollers

▪

Make sure that the rollers on the left and right

side of the MEWP are correctly installed.

▪

Make sure there is no visible damage.

▪

Make sure there is no dirt or blockages in the

rollers’ travel path.

6

Lift cylinder(s)

▪

Make sure that the lift cylinders are correctly

installed.

▪

Make sure there are no loose or missing

fasteners.

▪

Make sure there is no indication of leaks or

damage.

7

Angle transducer

▪

Make sure that the angle transducer is

correctly attached.

2. Retract the maintenance support(s) into their

storage brackets. Refer to Section 6.8-2.

3. Fully lower the platform.

Example model SJ3215 Example model SJ4740

1

6

3

2

4

5

7

1

6

3

2

4

7

5

Loading...

Loading...