213210AAAA SJ46 AJ, SJ51 AJ, SJ63 AJ

38

Section 4 – Inspections Before Operation Visual and daily maintenance inspections

4.2 Visual and daily

maintenance inspections

Do an inspection of the MEWP in this sequence.

WARNING

Do not operate a MEWP that does not function

correctly. Lock and tag the MEWP, and remove it

for servicing. Only a qualied service technician

must repair the MEWP. If you do not obey, there is

a risk of death or serious injury.

WARNING

Turn the main power disconnect switch to the

off position before you do the visual and daily

maintenance inspections. If you do not obey, there

is a risk of death or serious injury.

CAUTION

Make sure that the MEWP is on a rm, level

surface before you do the visual and daily

maintenance inspections. If you do not obey, there

is a risk of machine damage.

NOTE

When you do the visual and daily maintenance

inspections, make sure you do an inspection of

the limit switches, electrical components, and

hydraulic components.

4.2-1 Labels

Refer to Section 8 in this manual for the labels. Make

sure all the labels are in the correct location, are in good

condition, and you can read them.

4.2-2 Electrical

Do a check on these areas for chafed, corroded, and

loose wires:

▪

Boom to platform cable harness

▪

Engine compartment electrical panel

▪

Engine wiring harness

▪

Rotary manifold wiring.

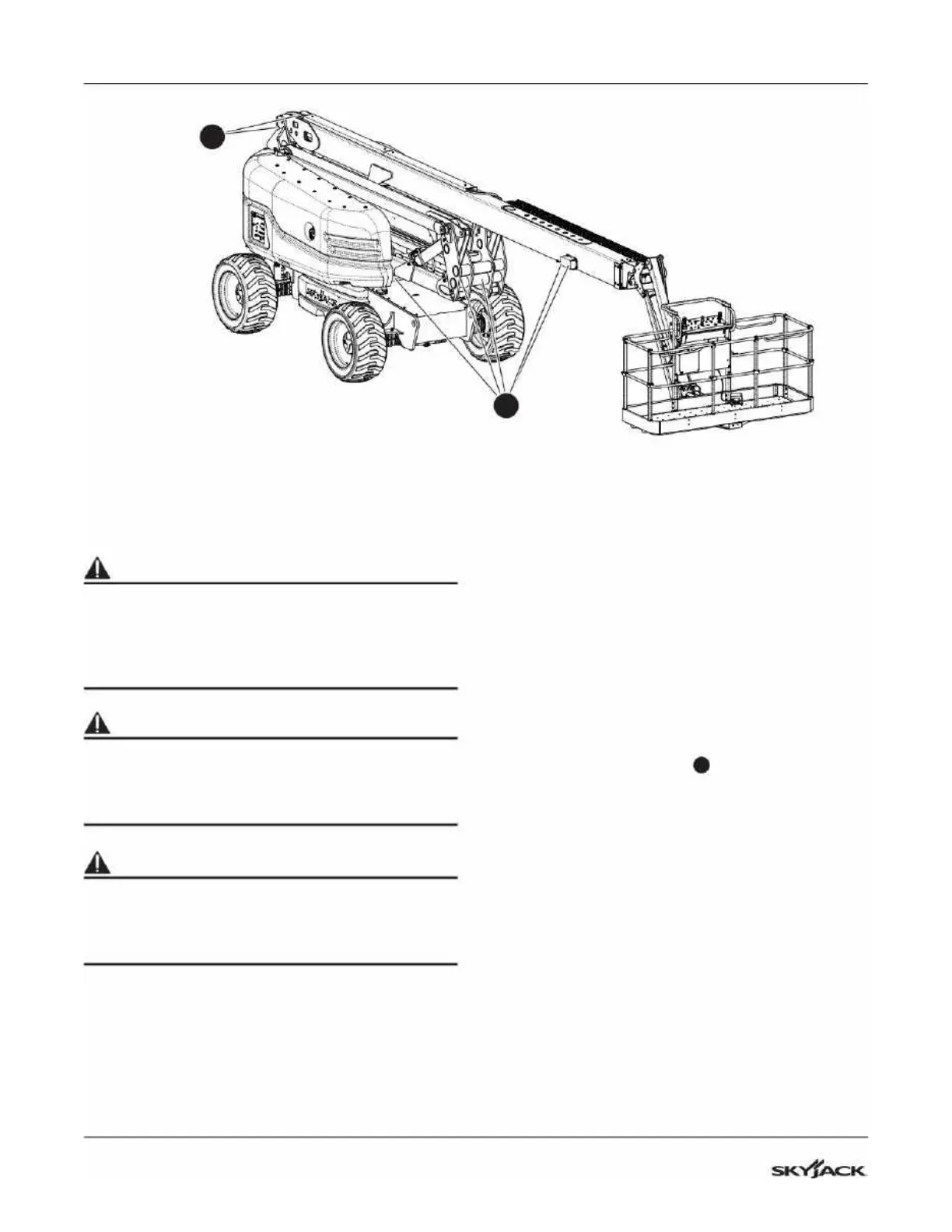

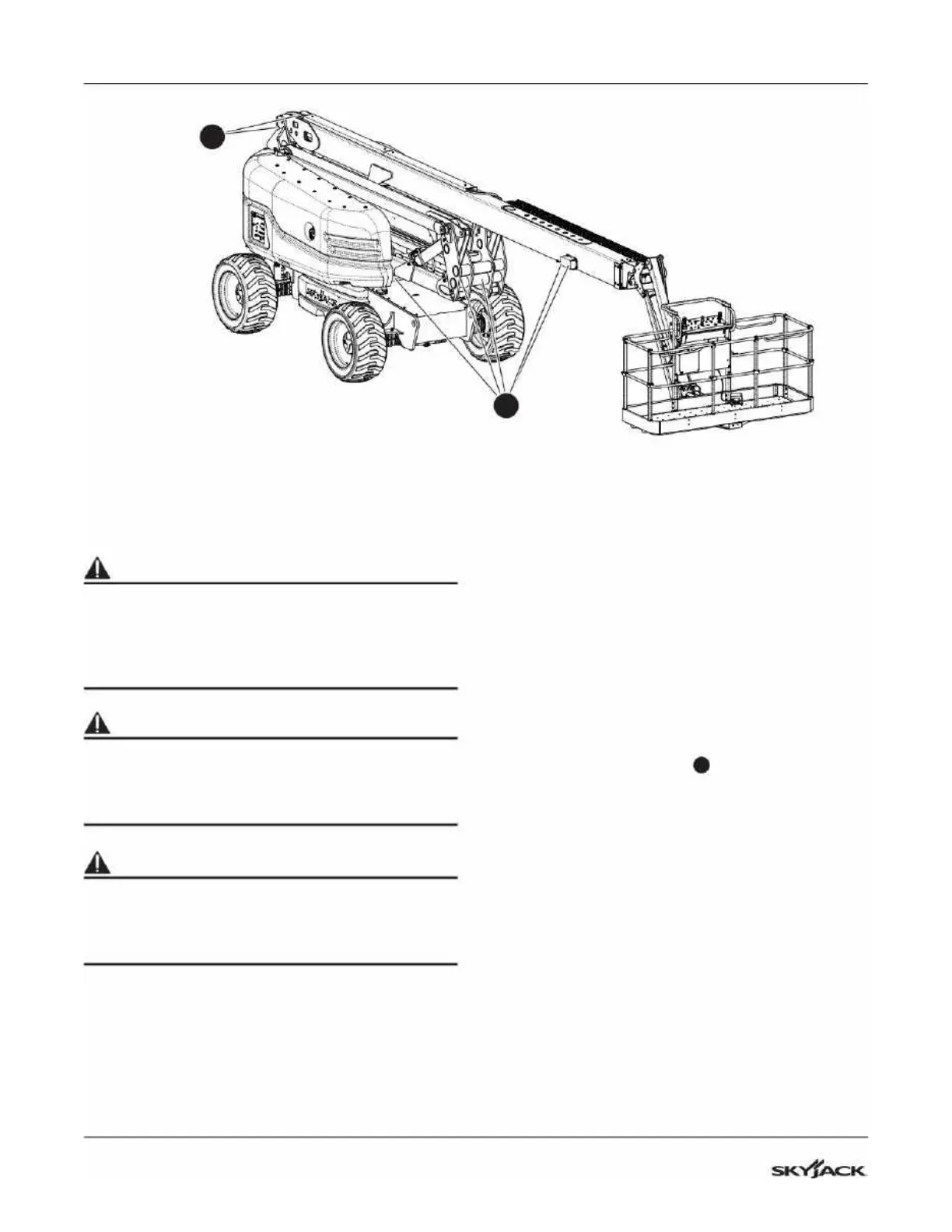

4.2-3 Limit switches

Make sure the limit switches

1

are correctly attached

with no visible damage, and the movement is not

blocked.

4.2-4 Hydraulic

Do a check on these areas and make sure there are

no signs of leakage:

▪

Hydraulic tank lter, ttings, hoses, emergency-

power unit, turret and base surfaces

▪

Engine compartment ttings, hoses, primary

pump, lter, turret and base surfaces

▪

All hydraulic cylinders

▪

All hydraulic manifolds

▪

The ground area below the MEWP.

Limit switch locations

1

1

Loading...

Loading...