Page 10

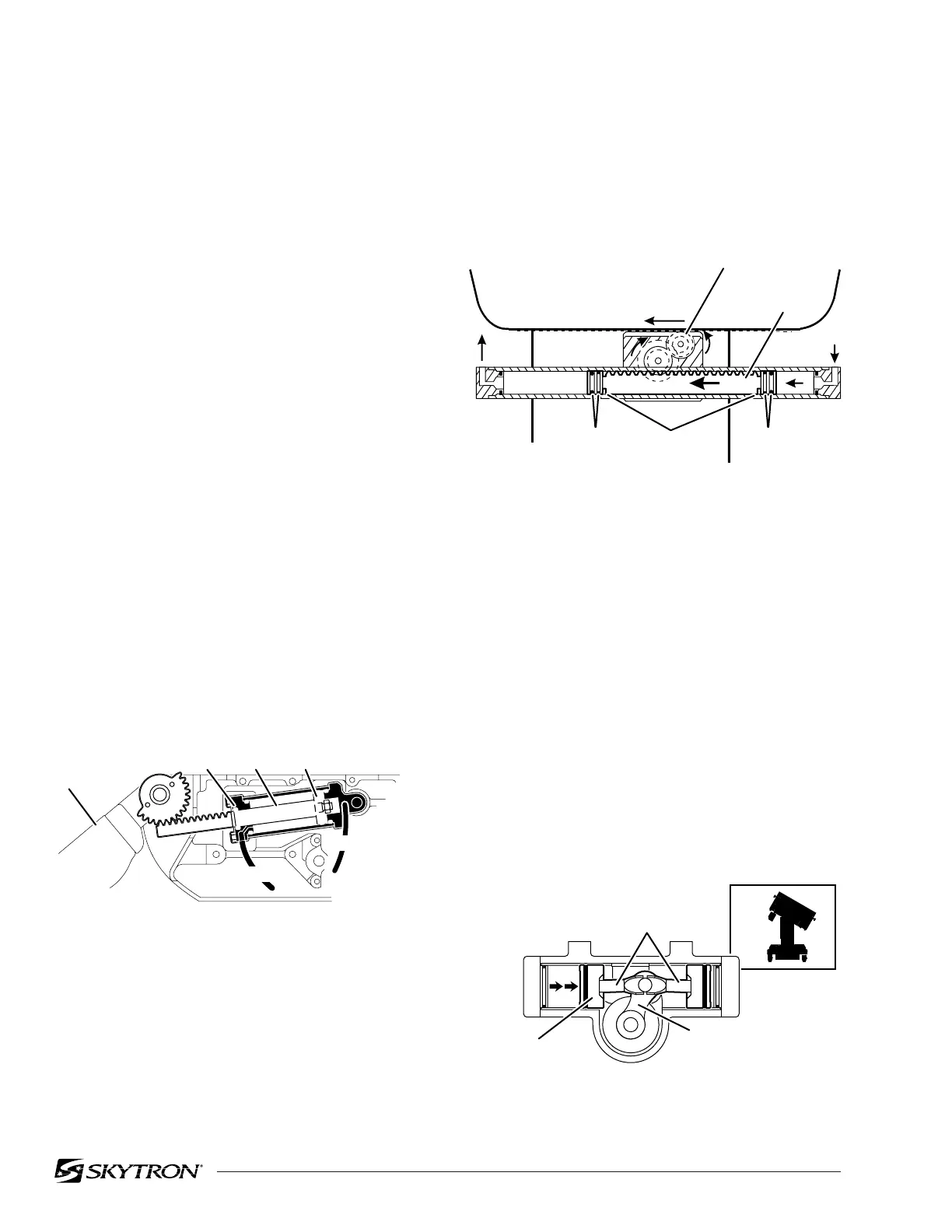

Figure 1-9. Slide Cylinder Assy.

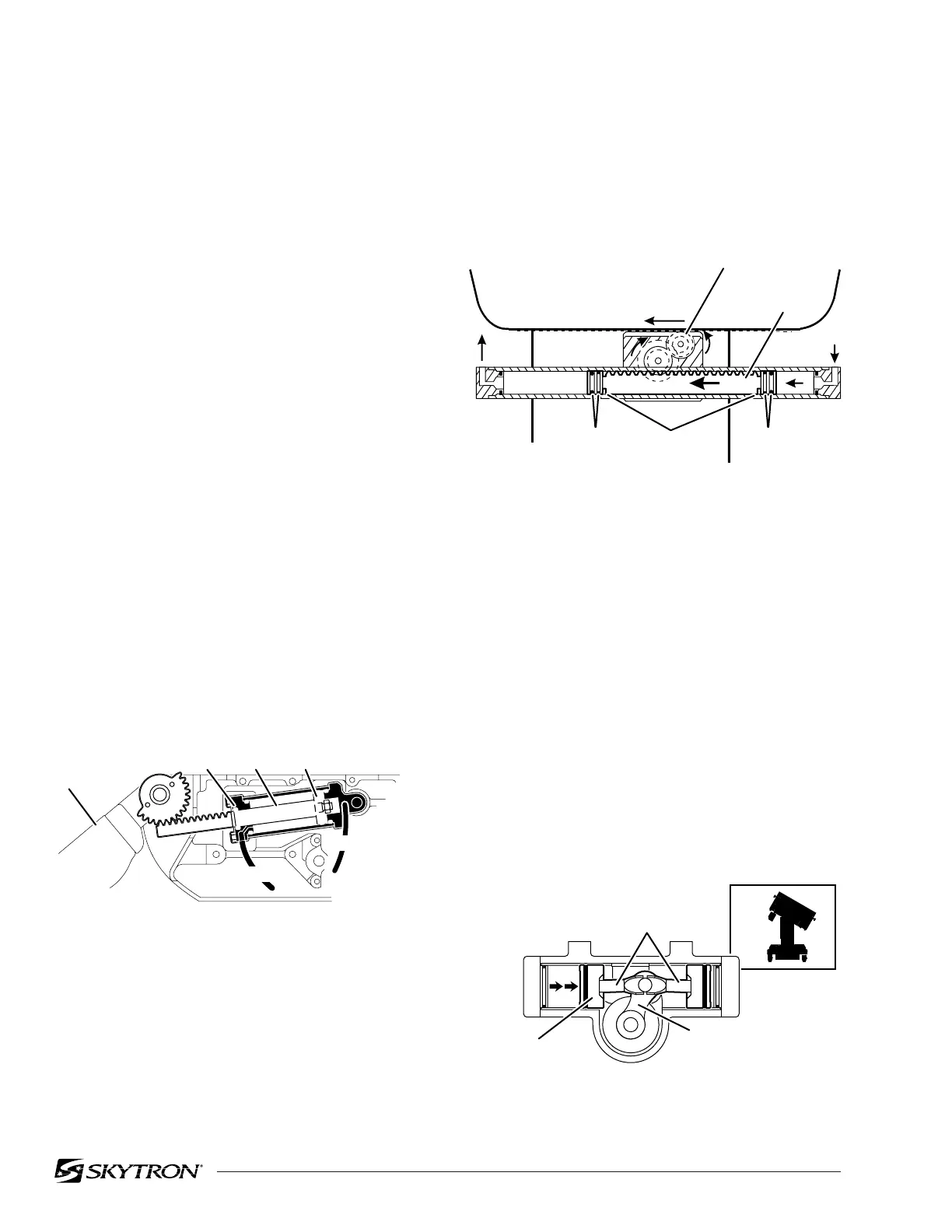

3. Lateral Tilt Assembly - The lateral tilt assem-

bly consists of two cylinders, pistons and connect-

ing rods. The connecting rods attach to the lateral

tilt lever which connects to the table center column

assembly. The cylinder housing attaches to the

table top and is attached to the center column

assembly by pivots. See figure 1-10.

The pistons and connecting rods are attached to a

non-movable surface. Therefore, when hydraulic

fluid is pumped into one side, the cylinder housing

itself moves around the lateral tilt lever causing the

table top to tilt to one side.

To tilt the table top in the opposite direction, fluid is

pumped into the opposite cylinder.

d. Hydraulic Cylinders (Slave Cylinders)

There are several different types of hydraulic cylin-

ders used in the table that activate the control

functions. With the exception of the elevation and

brake cylinders, all operate basically the same

way. The control functions are listed below.

Back Section ------ 2 double action cylinders

Leg Section ------- 2 double action cylinders

Trendelenburg ---- 1 double action cylinder

Lateral Tilt --------- 1 double action cylinder

Elevation ----------- 1 single action cylinder

Kidney Lift --------- 2 double action cylinders

Brakes -------------- 4 single action cylinders

Slide ----------------- 1 double action cylinder

1. Trendelenburg, Back Section and Leg Sec-

tion Cylinders - The double action cylinders are

closed at one end and have a movable piston with

hydraulic fluid on both sides. Connected to this

piston is a ram or shaft that exits out of the other end

of the cylinder. Through the use of a ball and

socket, a gear, or clevis and pin arrangement, this

ram is connected to a movable table surface.

The movable surface can be moved one way or

the other by pumping hydraulic fluid into the cylin-

der on either side of the piston. Obviously, if oil is

pumped into one side of the cylinder, a return path

must be provided for the oil on the other side. See

figure 1-8.

When hydraulic fluid is pumped into one side of the

cylinder, the pistons are pushed in one direction,

the gear arrangement rotates and causes the table

top to slide. Oil pressure can be applied to either

piston, making the table slide end for end. See

figure 1-9.

Figure 1-10. Lateral Tilt Cylinder Assembly

Figure 1-8. Back Section Cylinder

2. Slide Cylinder Assembly - This cylinder

arrangement has two pistons, one on each end of

a ram which has rack gear teeth cut into its top

surface. These teeth mesh with a gear arrange-

ment that drives a rack gear connected to the

bottom of the side frame.

RACK GEAR

82206-109

RAM

O-RINGSO-RINGS PISTONS

82206-108

BACK

SECTION

O-RING RAM PISTON

HYDRAULIC

LINE

HYDRAULIC

LINE

82206-110

LATERAL

TILT LEVER

CONNECTING RODS

PISTON

Loading...

Loading...