Page 43

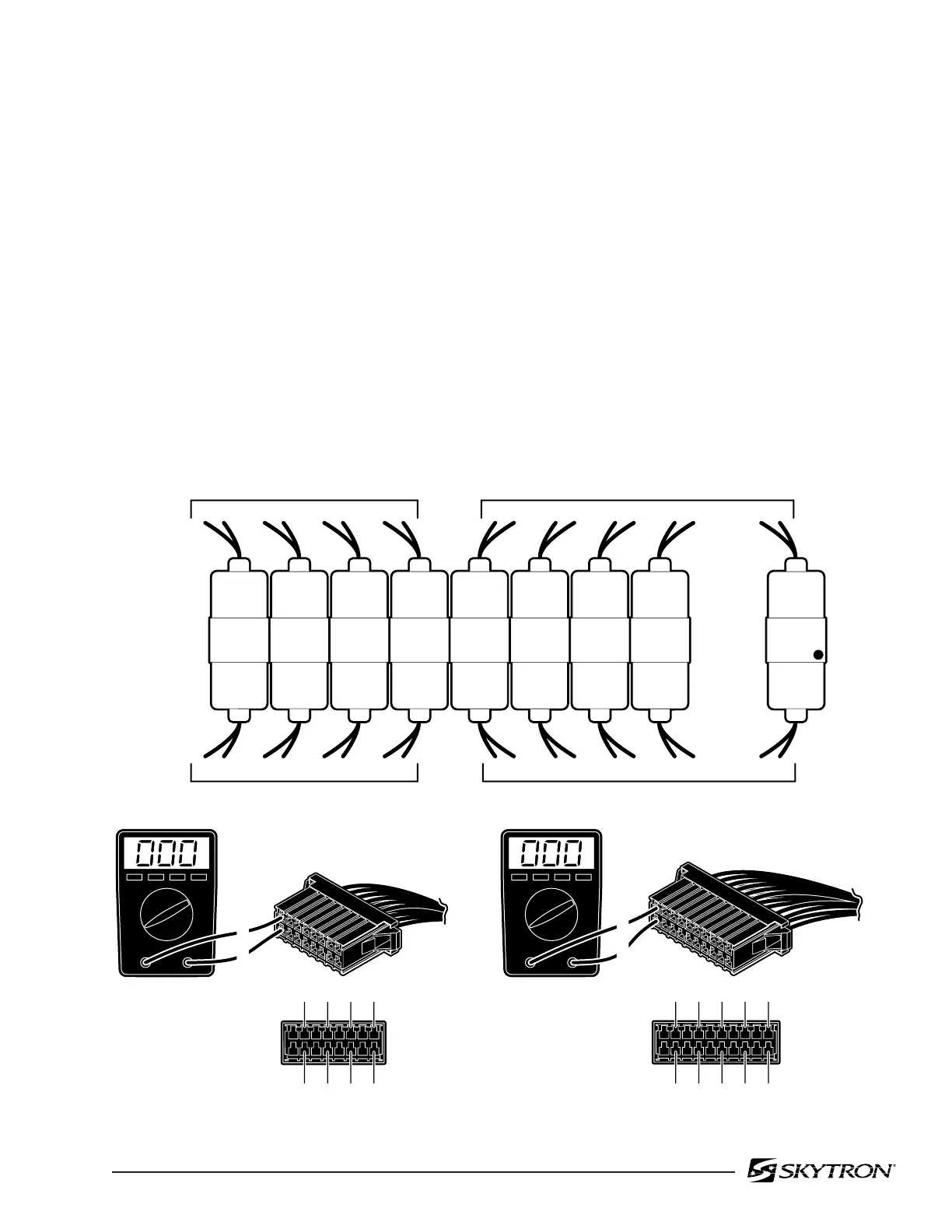

5-10. Solenoids

The solenoids are energized by 24 volt potential

that is controlled by the relay box. The solenoid

windings are protected from excessive heat by

an internal thermal fuse that will open after

approx. 7 minutes of continuous operation. The

solenoid must be replaced if the internal thermal

fuse has been blown. The solenoids are mounted

directly on either side of the hydraulic mini-valves

and push the spool valve in one direction or the

other depending upon which solenoid is activated.

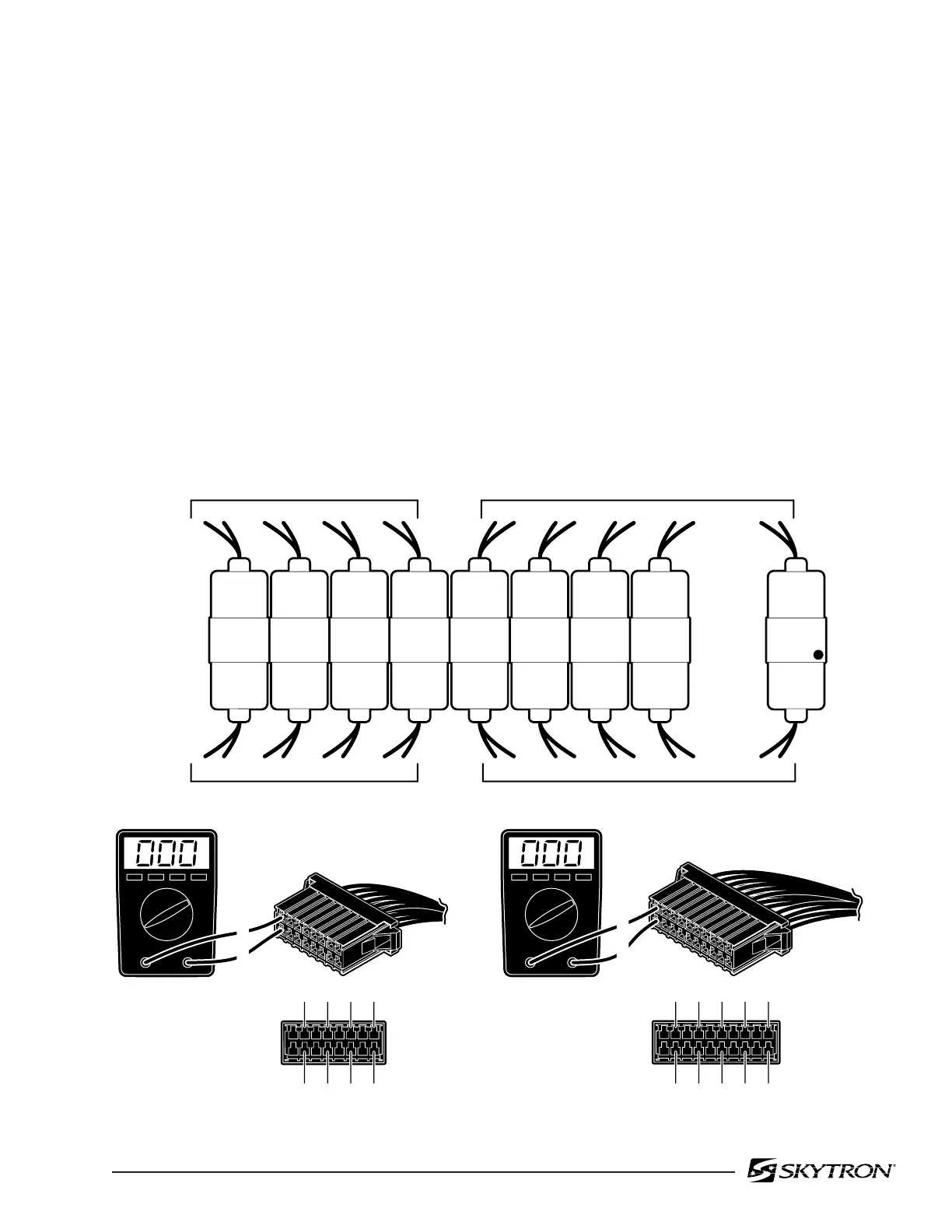

a. Solenoid Test

The resistance of the solenoid coil can be

checked out using an ohmmeter R x 1 scale.

1. Disconnect connectors CN1A and CN1B.

Measure the resistance between the two pins at

the connector for the solenoid in question as shown

in figure 5-17. Polarity of meter leads is not

important.

2. The meter should read approximately 16

ohms at room temperature.

3. Measure the resistance between either

pin and ground.

4. Meter should read infinity.

b. Test Results:

If the solenoid does not check out with the meter,

it is more than likely defective and must be

replaced.

Figure 5-17. Solenoid Test

82306-516

ELEVATION

Up

Down

TREND.

Trend

Reverse

Trend.

LATERAL

TILT

Right

Left

FLEX

Reflex

Flex

BRAKE

Unlock

Lock

BACK

SECTION

Up

Down

Down

Up

KIDNEY

Up

Down

SLIDE

Foot

Head

LEG

SECTION

12 56

CN1A

910 1314

12

15 16 11 12 19 20

34 78

11 12

15 16

3

413

14

910 1718

56

78

CN1B

CN1A

CN1B

1

2

19

20

17

18

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

CN1B

1

2

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

CN1A

BLUE DOT

Loading...

Loading...