Page 17

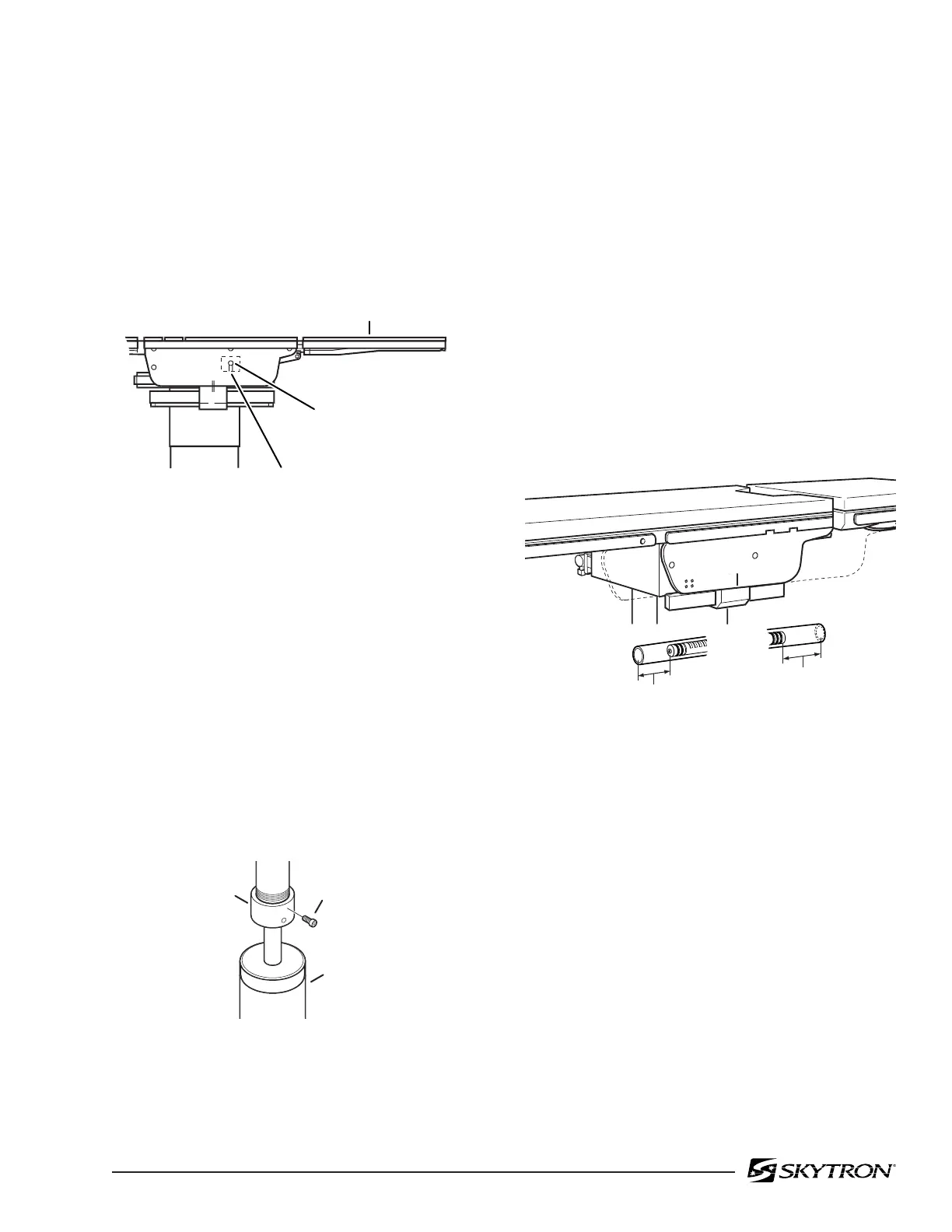

To adjust:

Loosen the cam locking set screws located inside

the table side frames. See figure 2-3. Use an allen

wrench to turn the cylinder eccentric cams as

required to shift either cylinder fore or aft as needed

so no twisting or flexing of the leg section is

observed when it is stalled in the above horizontal

position. Tighten set screws when proper adjust-

ment is achieved.

Figure 2-3. Leg Section Adjustment

c. Trendelenburg Cylinder Ball Joint

Inspect the Trendelenburg ball joint on a periodic

basis. Check for play of table top by sliding the table

top to each extremity and applying a load. Observe

for any movement in the joint. No visible play is

permitted. If movement is observed inspect the

tightness of the ball joint collar and the locking allen

bolt. See figure 2-4. Also inspect the ball socket for

signs of wear or metal particulate. Lubricate peri-

odically using a white lithium based grease.

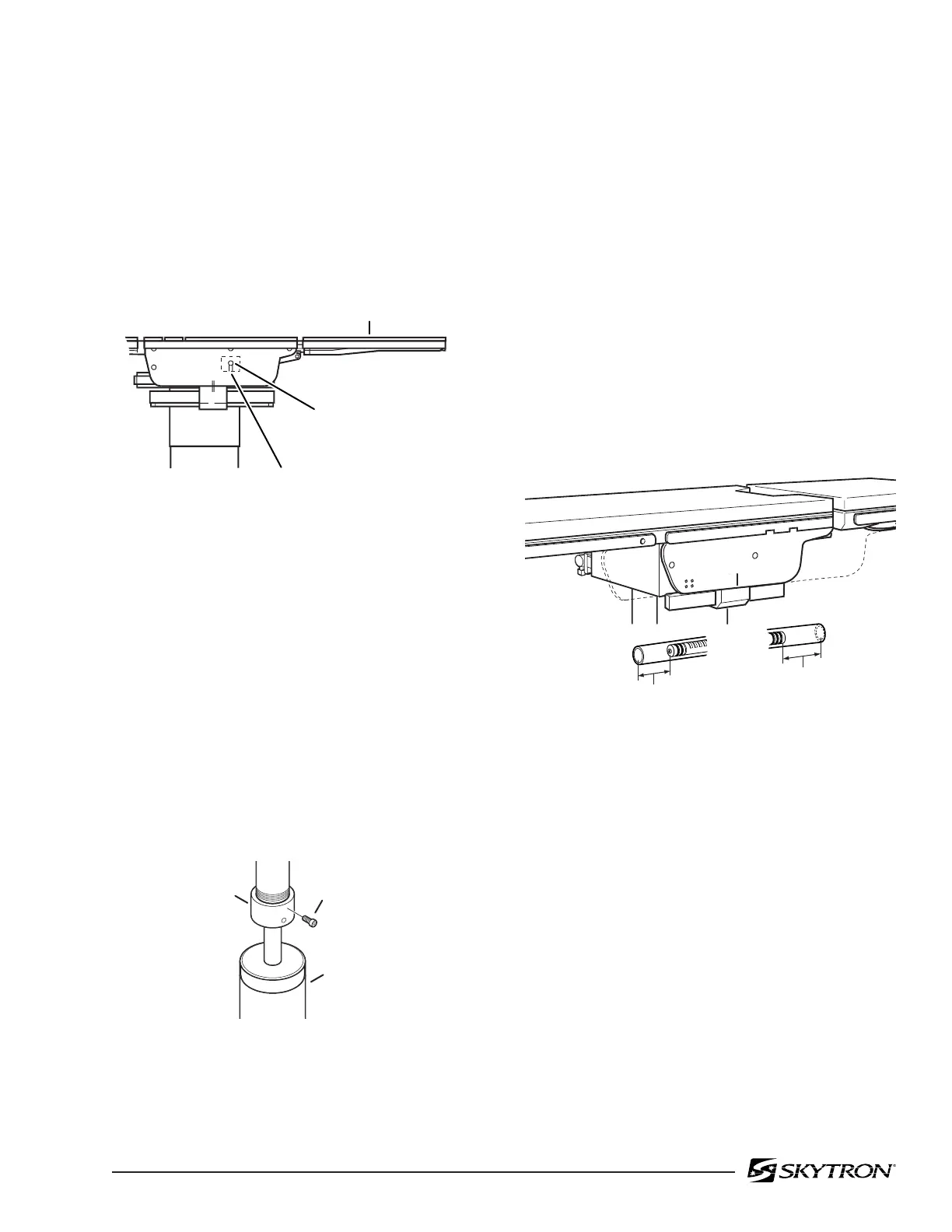

d. Slide and Kidney Lift Cylinders

If the Slide or Kidney Lift cylinder has been re-

moved, the distance from the end of the piston to

the end of the cylinder housing must be checked to

make sure the functions will operate correctly.

With table top centered, the distance from the

end of the Slide piston to end of cylinder is:

Head End - 82 mm Foot End - 120 mm

The table top should slide 7-1/2" toward the head

and 13-1/4" toward the foot when positioned prop-

erly. Refer to figure 2-5.

With Kidney Lift all the way down, the distance

from the end of the Kidney Lift piston to end of

cylinder is:

Head End - 82 mm Tail End - 11 mm

LEG SECTION

SET SCREW

LEG SECTION

CYLINDER

ECCENTRIC CAM

82206-203

82mm

120mm

7-1/2"

SLIDE

TOWARD

HEAD

13-1/4"

SLIDE

TOWARD

FOOT

82206-204

Figure 2-4. Trendelenburg Cylinder

Figure 2-5.

2-3. Head Section Adjustment

The head section can be adjusted to eliminate any

flexing throughout it's range of travel.

To adjust:

Place the head section in level position and remove

the top. See figure 2-6. Loosen but do not remove

the allen bolts securing the bearing block to the

frame. Loosen the allen bolt in the top of the frame

and turn the set screw as required to achieve

proper adjustment. One or both of the blocks may

require adjustment to achieve proper alignment.

Tighten all allen bolts when adjustment is com-

plete. Test the head section throughout its range of

travel. Re-adjust as needed. Replace top section

when proper adjustment is achieved.

ALLEN BOLT

TRENDELENBURG

CYLINDER

BALL JOINT

COLLAR

82106-101

Loading...

Loading...