Page 23

3-6. FLEX SYSTEM DIAGNOSIS CHART

Reason

Incorrect Speed Adjustment (Trendelenburg, Back

section or Flex - check with gauge)

Spool Valve Not Centered

Defective Check Valves

Low on Oil

Pinched Hose

Defective Mini-Valve

Pressure Relief Valve Not Set Properly

Defective Solenoid

Defective Relay Box or Pendant Control

Kidney Bridge Raised

Worn Ball Joint or Retainer Nut

Defective or Dirty Check Valves

Oil Leakage in Circuit

Air Inside Cylinder

Pinched Hose

Low on Oil

Problem

Back Section or Trendelenburg function moves

improperly

NOTE

If Flex System does not function prop-

erly, check the back section and

Trendelenburg functions before ad-

justing the flex system.

Back Section or Trendelenburg function chatters

or loses position

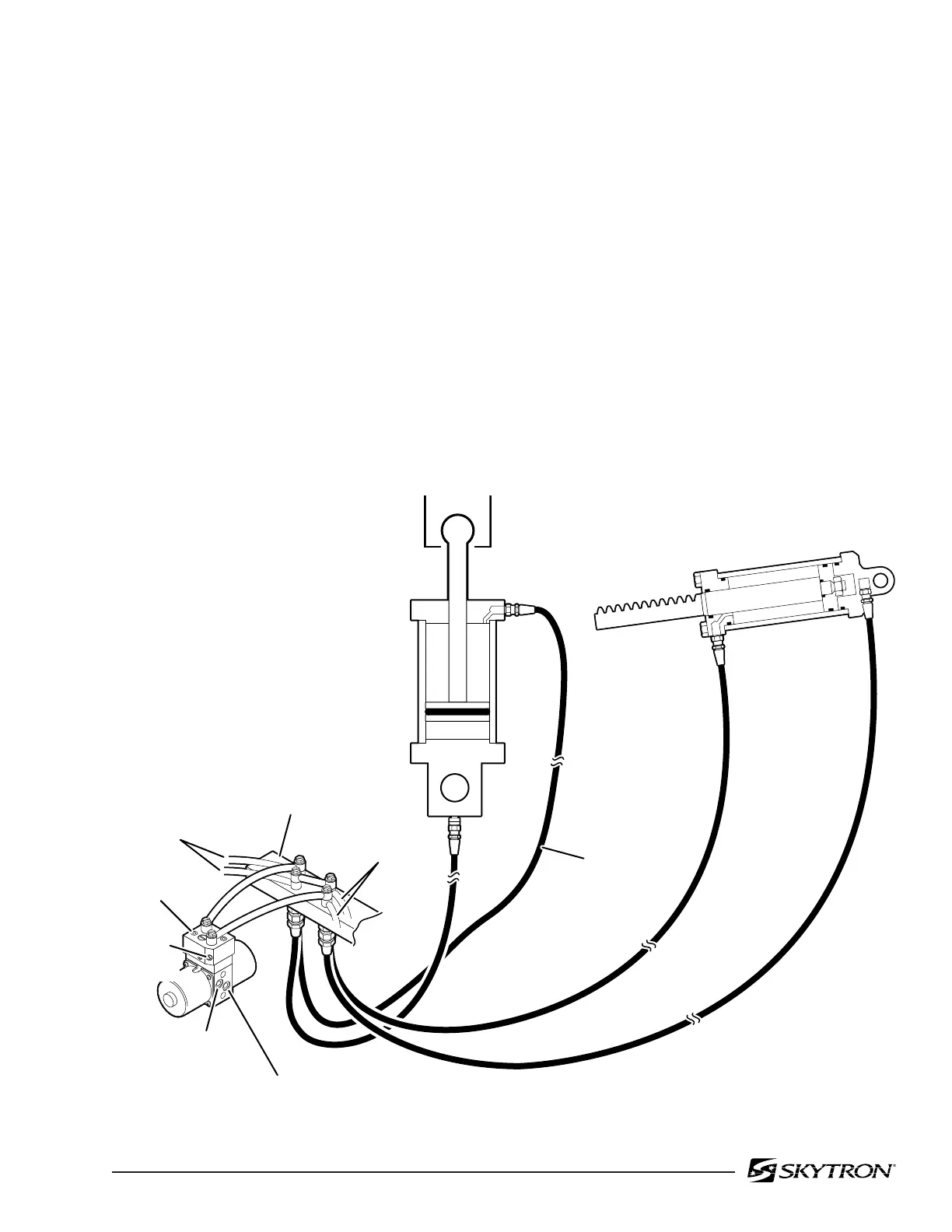

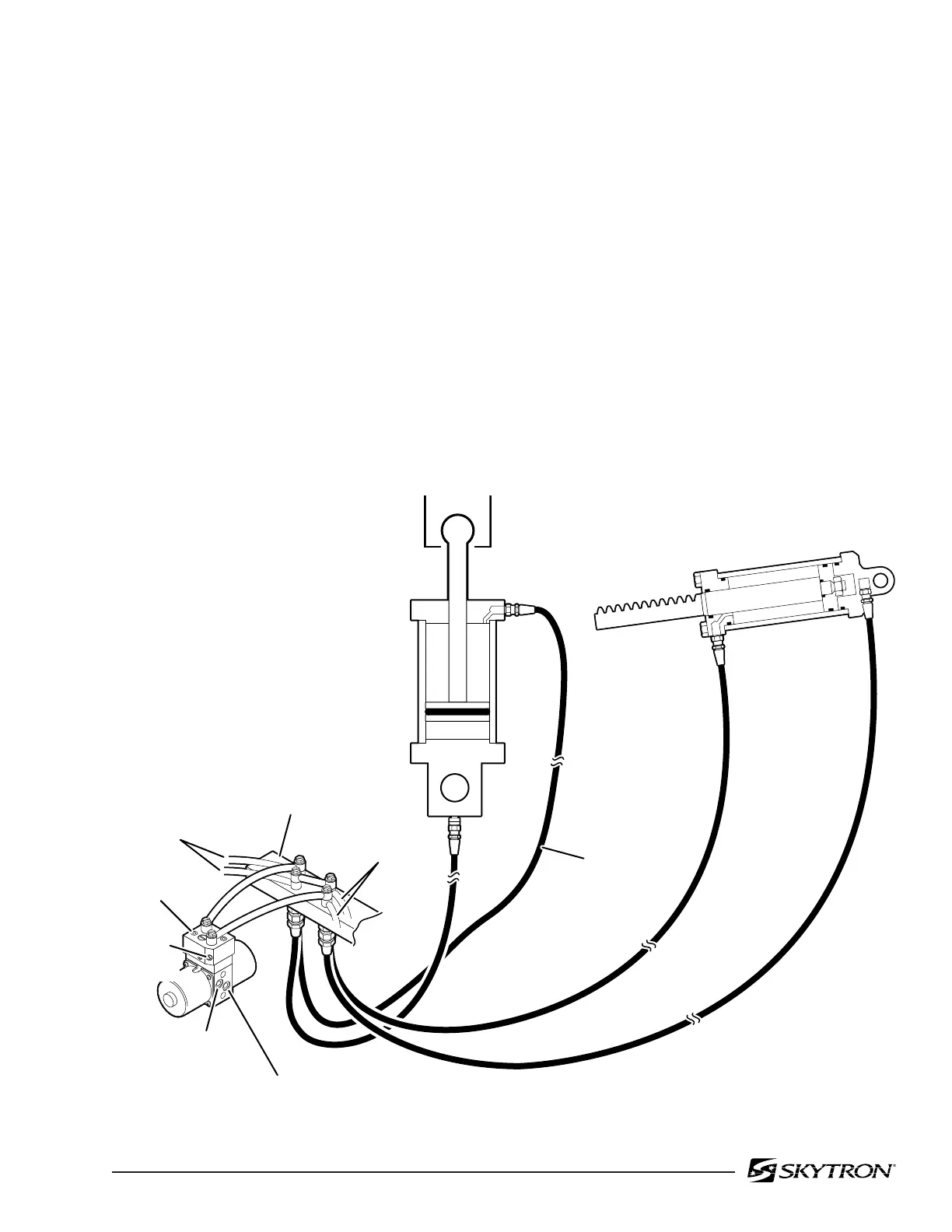

Figure 3-4. Flex System Circuit

82206-304

TO TRENDELENBURG

MINI-VALVE

TO BACK SECTION

MINI-VALVE

SPEED

CONTROL

CHECK

VALVE

PLUMBING

TERMINAL

TRENDELENBURG

CIRCUIT

BACK SECTION CIRCUIT

MINI-VALVE

INTERNAL OIL RETURN TO RESERVOIR

INTERNAL

OIL FROM PUMP

FLEXIBLE

HOSE

Loading...

Loading...