S

L

series - Use and maintenance manual

39

Translation from the original

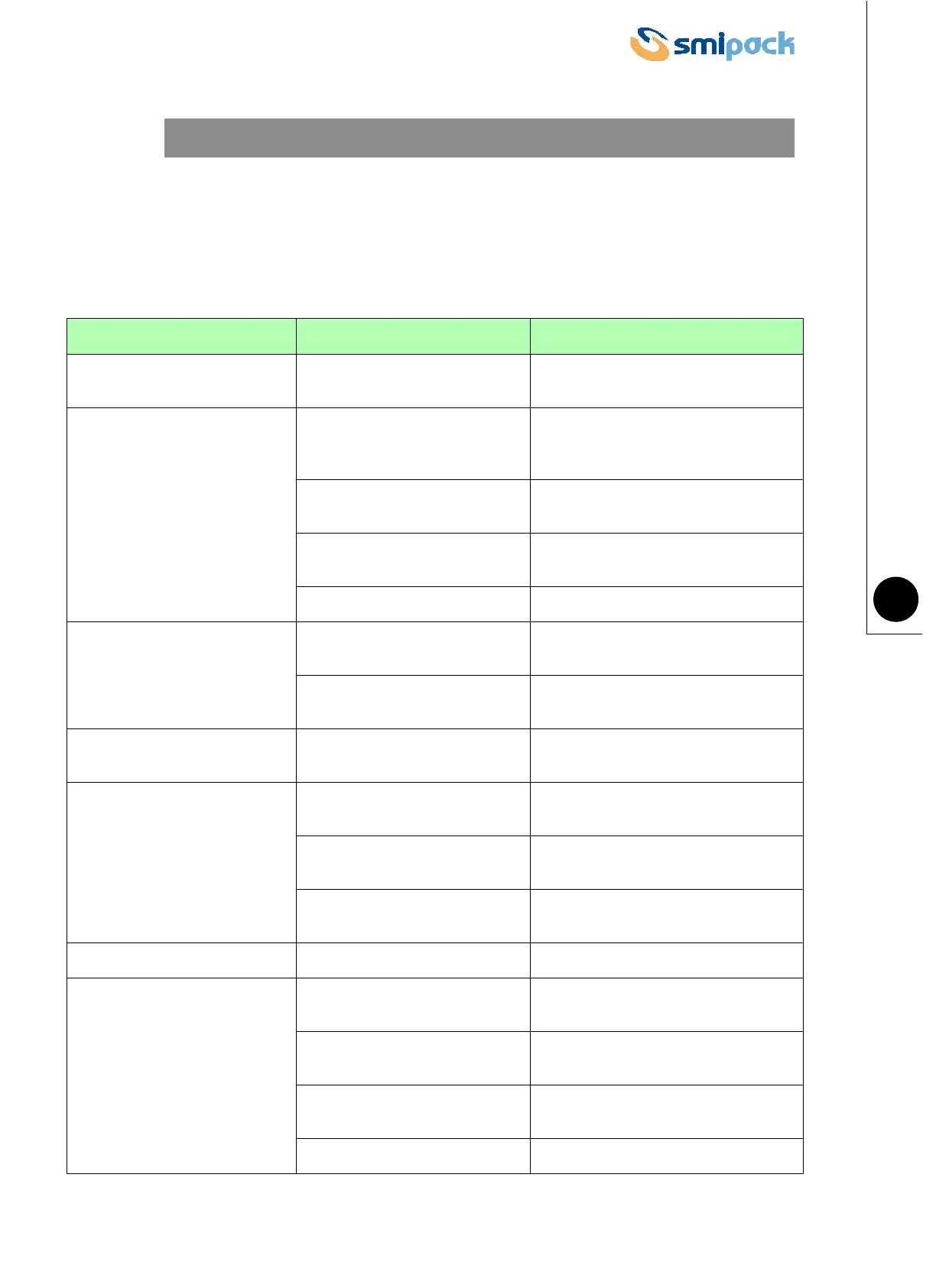

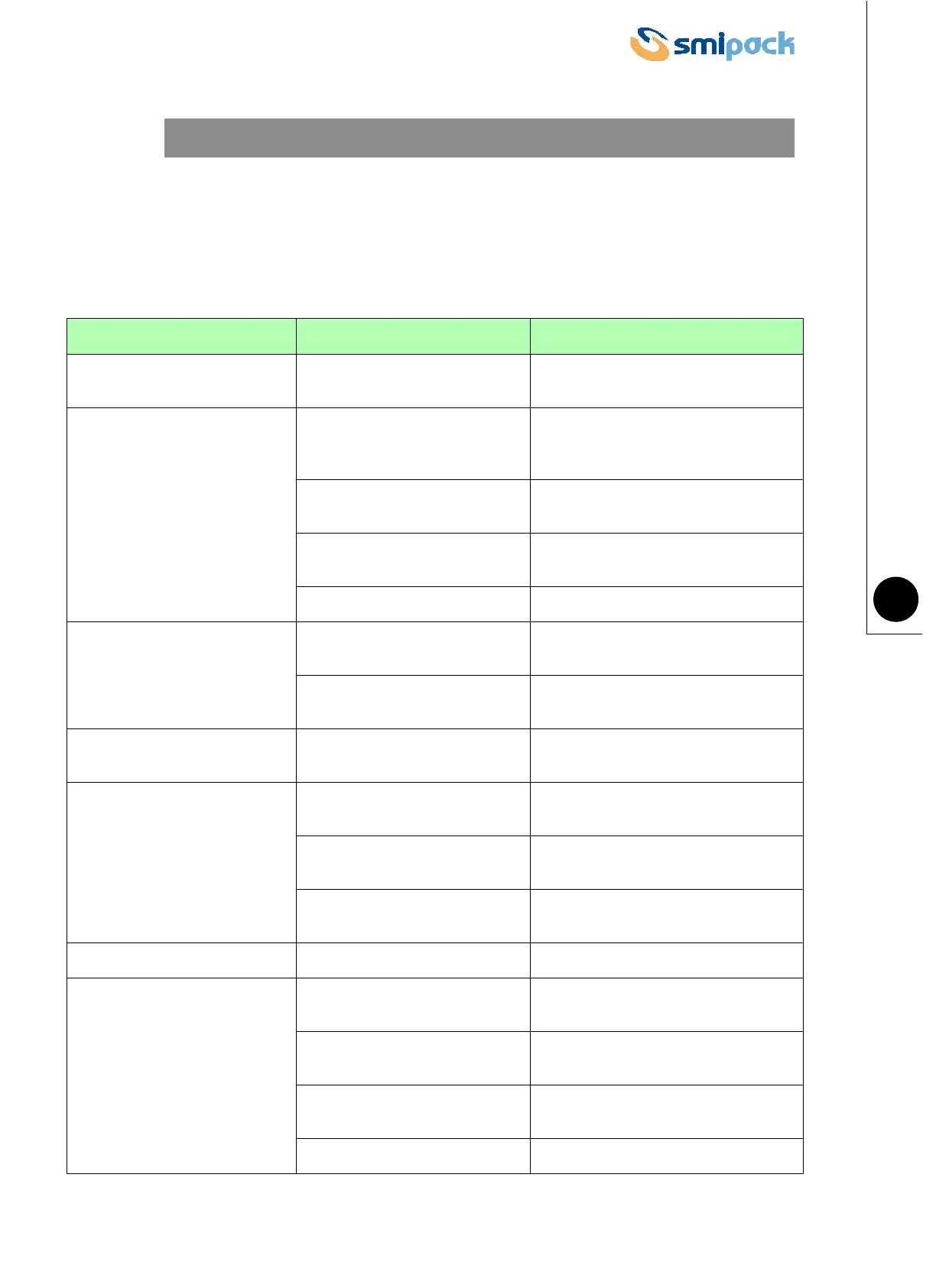

7.1 SOLUTIONS TO OPERATING PROBLEMS

The following table describes the solutions to the most common problems which can occur

while the machine is operating.

CHAPTER 7 - ANOMALIES AND FAULTS - HOW TO RESOLVE

PROBLEM CAUSE SOLUTION

PRESENCE OF SMOKE DURING

SEALING

The sealing temperature is set

too high.

Lower the sealing temperature.

THE MACHINE PERFORMS

SEALING BUT NOT HEAT

SHRINKING

Heat shrinking mode has not

been selected.

Make sure that the symbol indicating

that shrinking is active appears on the

display

The heat shrinking temperature is

too low.

Check the temperature level on the

circuit board display.

The heating elements are in the

heating up phase.

Wait for the heating elements to reach

the set operating temperature.

The fan does not work. Probable fan motor fault.

HEAT SHRINKING IS

IMPLEMENTED BUT IS NOT

EVEN AND COMPLETE

The film used is unsuitable or

poor quality.

Replace the film used for packaging.

The product is too big.

See chapter 3 section “technical

specifications of the product”..

BUBBLES REMAIN AFTER

HEAT SHRINKING

The film has no micro

perforations.

Pass the film through the machine micro

perforators.

SEALING OPENS DURING HEAT

SHRINKING

The sealing blade is dirty or

damaged.

Clean the sealing blade or replace it if

damaged.

The sealing value set in the

“parameters menu” is incorrect.

Adjust the sealing parameter more

accurately.

Insufficient pressure is applied on

the hood.

Slightly increase pressure on the hood

handle during the sealing phase.

IRREGULAR SEALING

Low-quality film has been used. Replace the film.

THE FILM IS NOT SEALED

The sealing temperature is set too

low.

Increase the sealing temperature.

The sealing blade does not

receive properly.

Repair the power circuit of the sealing

blade.

The PTFE and/or silicon rubber

are worn.

Replace the PTFE and/or silicon rubber

The sealing blade is damaged. Replace sealing blade.

Loading...

Loading...