75 / 284

Use and maintenance manual

T450 - T650E - T650EF - T650 - T650F

ENGLISH

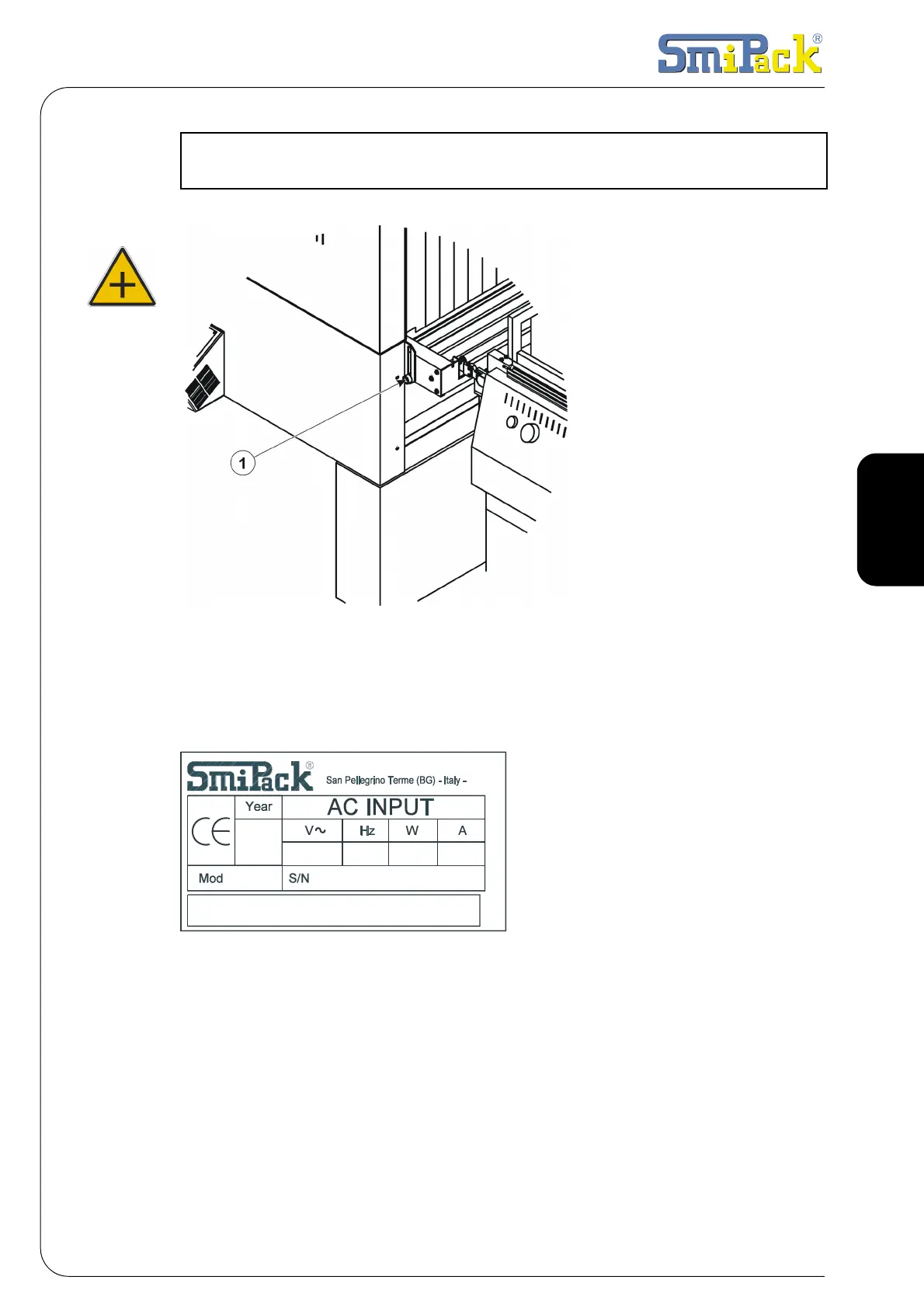

The T series tunnel has been

designed to heat shrink the film.

The tunnel's conveyor belt is

connected to the machine's belt

FP end BP. For a good

packaging, film sealing must

take place at half the product

height. The raising (or the

lowering) of the belt implicates

the regulation of the tunnel's

curtain, this is necessary as it is

essential not to disperse heat

during the heat-shrinking

operation.

Adjust the height of the T650

tunnel and lock the belt with the

two screws 1.

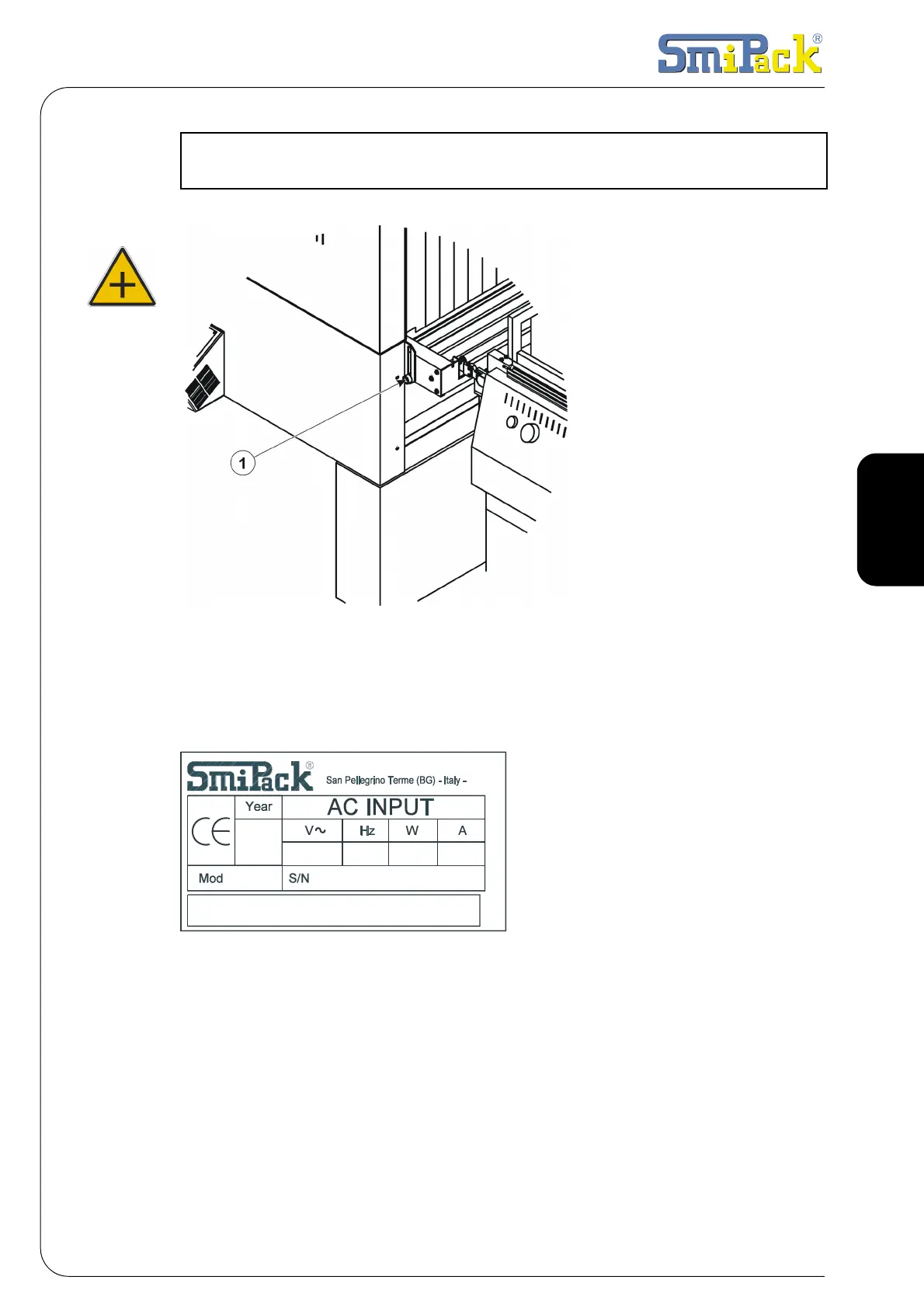

3.1 TUNNEL IDENTIFICATION

Fig. 3.1.1

On the rear of every tunnel

there is a data plate showing

the EC marking, the main

technical data such as model,

serial number, power, etc., that

will be notified to the builder in

case of problems.

3.2 SHRINKING

Film shrinking is obtained in the oven and is produced by the forced circulation of hot

air around the packaging. Air heating is obtained by making the same go through a

group of thermo-controlled resistors: a centrifugal fan moves the air. If the sealing

breaks during the shrinking it is possible to increase the speed of the belt or to lower

the temperature of the resistors by acting on the tunnel's control panel. Air heating is

obtained by making the same go through a group of thermo-controlled resistors: a

centrifugal fan moves the air. If the sealing breaks during the shrinking it is possible to

increase the speed of the belt or to lower the temperature of the resistors by acting on

the tunnel's control panel.

3. INFORMATION ON THE TUNNEL

Loading...

Loading...