Page18

Section6 Operating Procedures

Sanitizing

Step 1

Prepare 3.8 liters of an approved 100PPM sanitizing solution. USE WARM WATER

AND FOLLOW THE MANUFACTURER’S SPECIFICATIONS.

Step 2

Pour 3.8 liters of sanitizing solution into the hopper and allow it to flow into the freezing

cylinder.

Step 3

While the solution is flowing into the freezing cylinder, brush-clean the mix hopper, mix

level stem, mix inlet hole, and air tube.

Step 4

Press the Wash Keypad. This will cause the sanitizing solution in the freezing cylinder

to be agitated. Allow it to agitate for five minutes.

Step 5

Place an empty pail beneath the door spout and raise the draw valve. Draw off all of the

sanitizing solution. When the sanitizer stops flowing from the door spout, lower the

draw valve and place the power switch in the “OFF” position.

Step 6

With sanitized hands, stand the air tube in the corner of the mix hopper.

Step 7

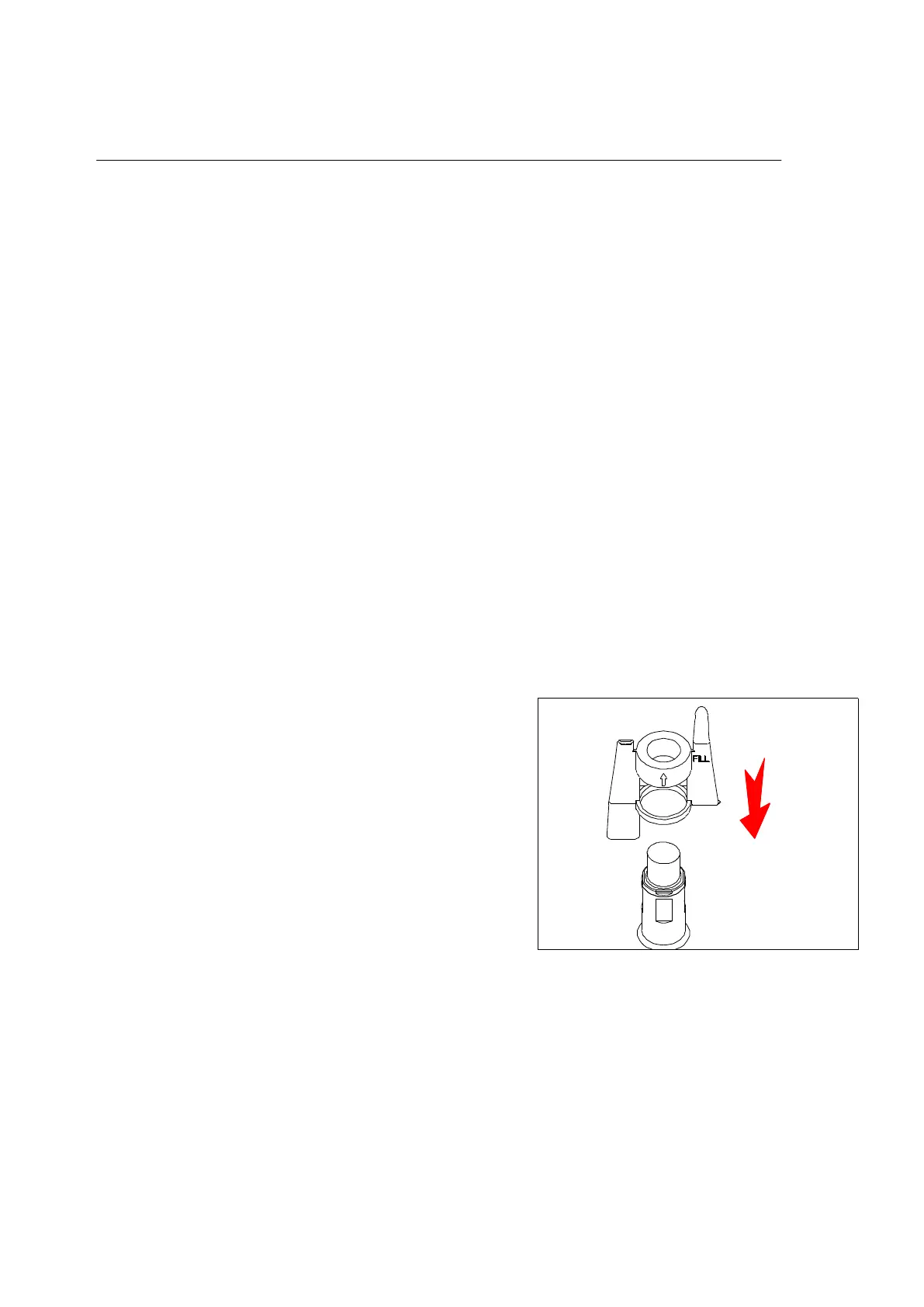

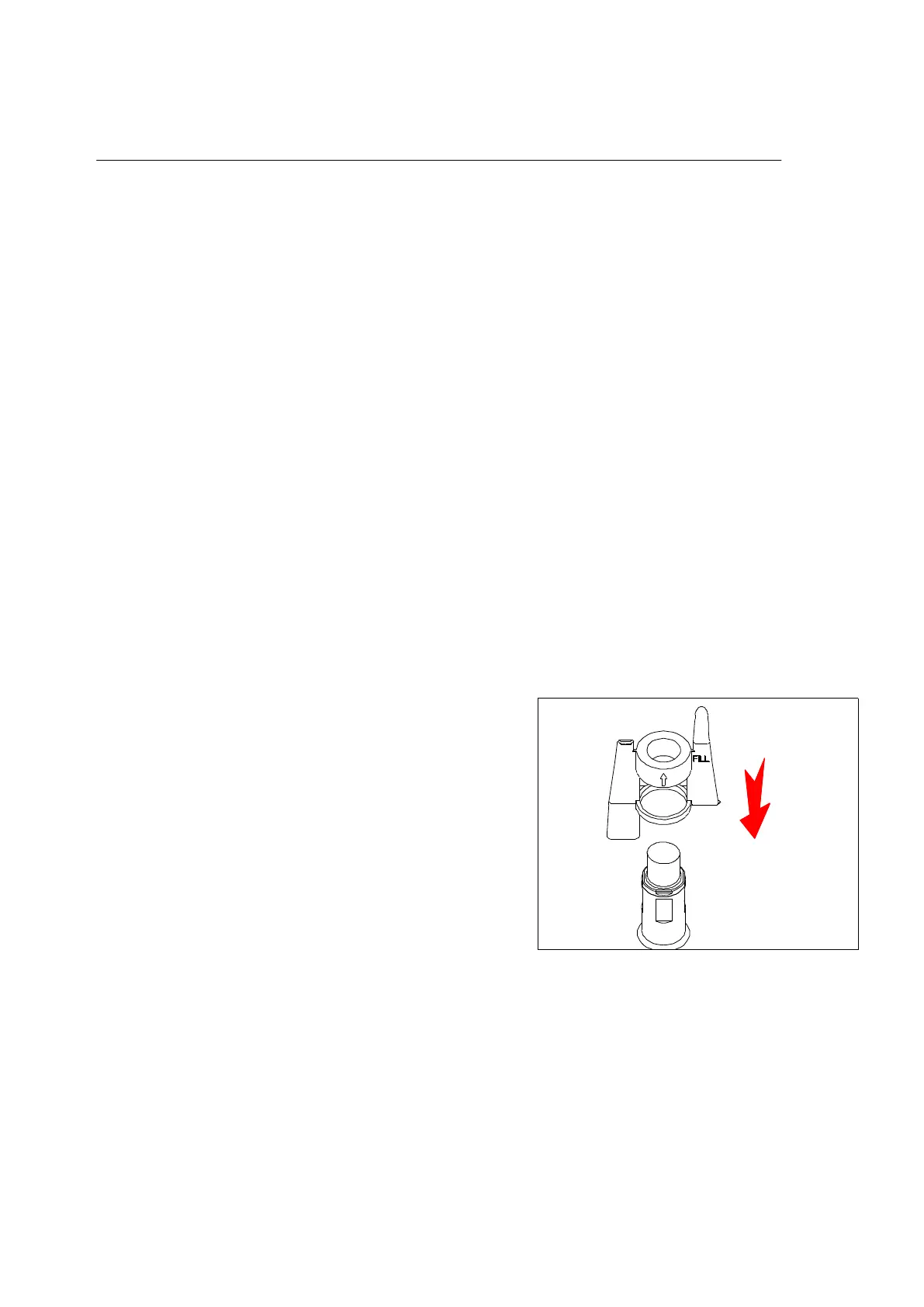

Place the agitator on the agitator drive shaft

housing. Figure 6-2

Note: If agitator should stop turning during normal

operation, with sanitized hands, remove agitator

from agitator drive shaft housing and brush clean

with sanitizing solution. Install the agitator back onto

the agitator drive shaft housing.

Priming

Prime the machine as close as possible to the time of first product draw.

Never: 1. Too much water in the mix.

2. Cool Keypad in “ON” when only water in the hoppers and evaporators.

3. Cool Keypad in “ON” when no mix or in the hoppers and evaporators or

only in one hopper and evaporator.

Step 1

Install the air tube in the mix inlet hole.

Loading...

Loading...