Page24

Section7 Important: Operating Checklist

Regular Maintenance Checks

1. Check the rear shell bearing for signs of wear (excessive mix leakage in rear drip pan)

and be certain it is properly cleaned.

2. Using a screwdriver and cloth towel, keep the rear shell bearing and the female hex

drive socket clean and free of lubricant and mix deposits.

3. Dispose of O-rings or seals if they are worn, torn, or fit too loosely, and replace with

new ones.

4. If an overload condition occurs frequently, maybe the belt is worn, torn, or fit too

loosely. Dispose of the belt and replace with new ones.

5. Follow all lubricating procedures as outlined in ASSEMBLY.

6. This machine is air cooled, check the condenser for an accumulation of dirt and lint.

A dirty condenser will reduce the efficiency and capacity of the machine. Condensers

should be cleaned monthly with a soft brush. Never use screwdrivers or other metal

probes to clean between the fins. Failure to comply may result in electrocution.

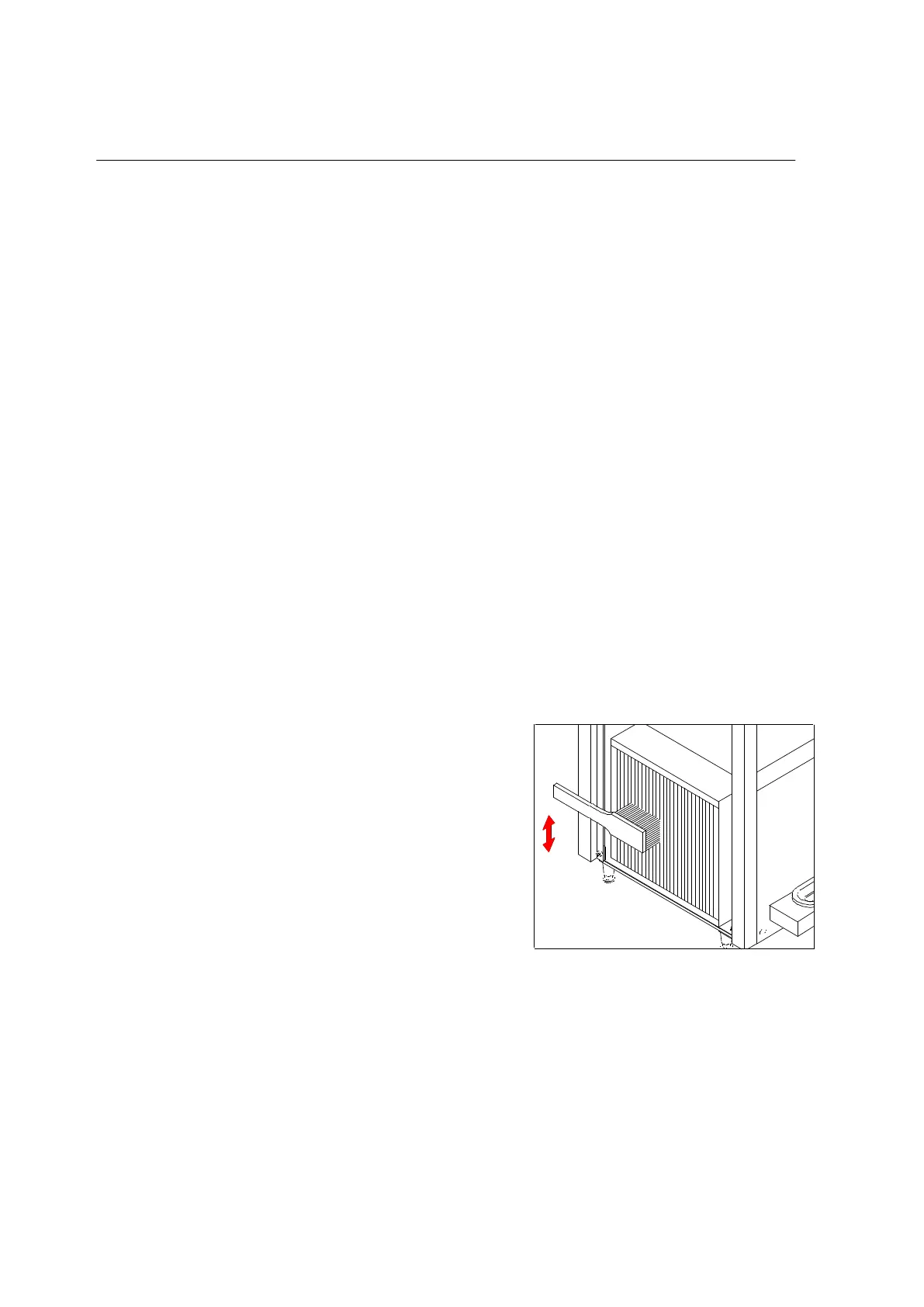

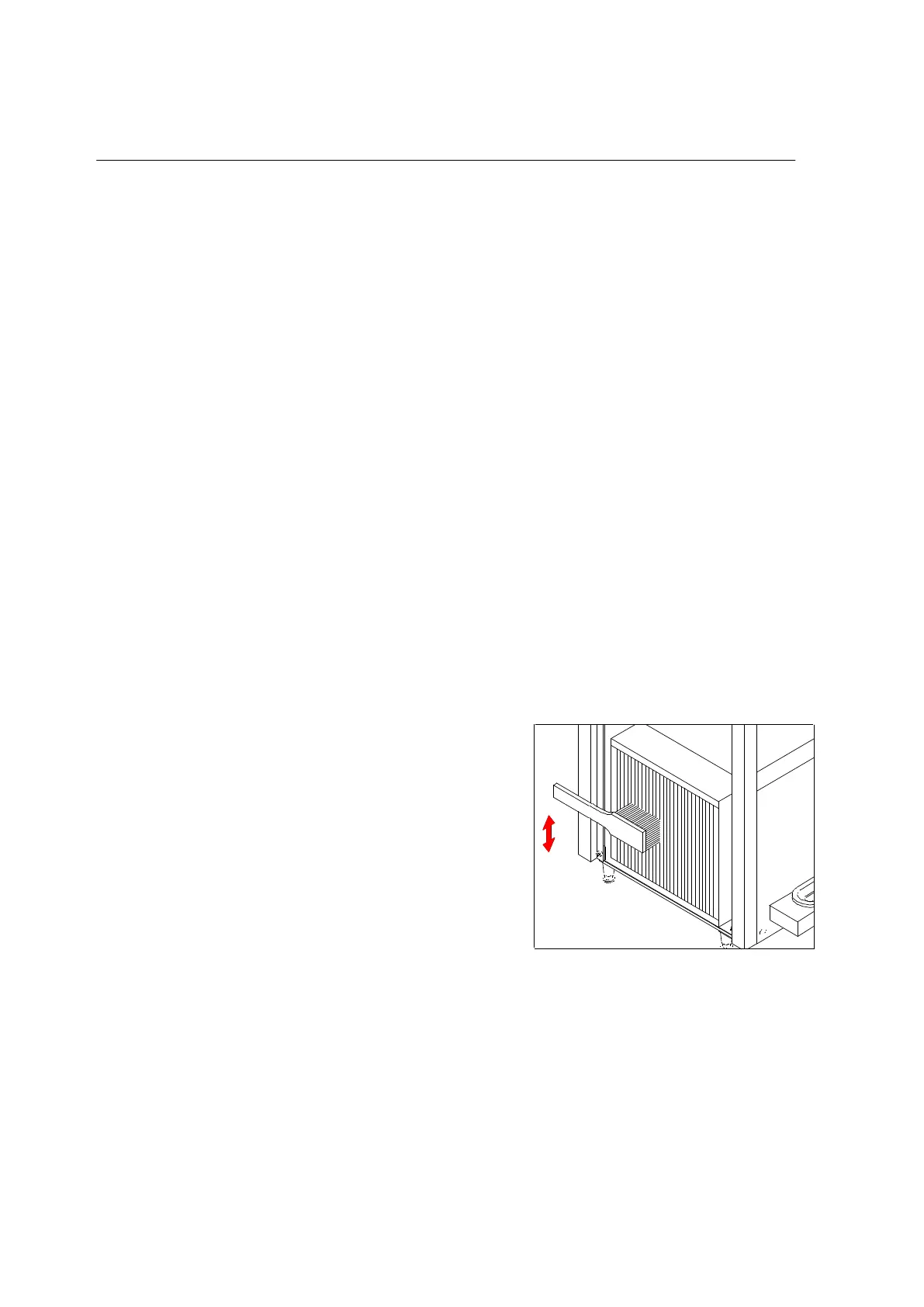

7. This machine is equipped with an auxiliary

refrigeration system; check the auxiliary

condenser will reduce the refrigeration

capacity of the mix hopper. Condensers

must be cleaned monthly with a soft brush.

Never use screwdrivers or other metal

probes to clean between the fins. Failure

to comply may result in electrocution.

Loading...

Loading...