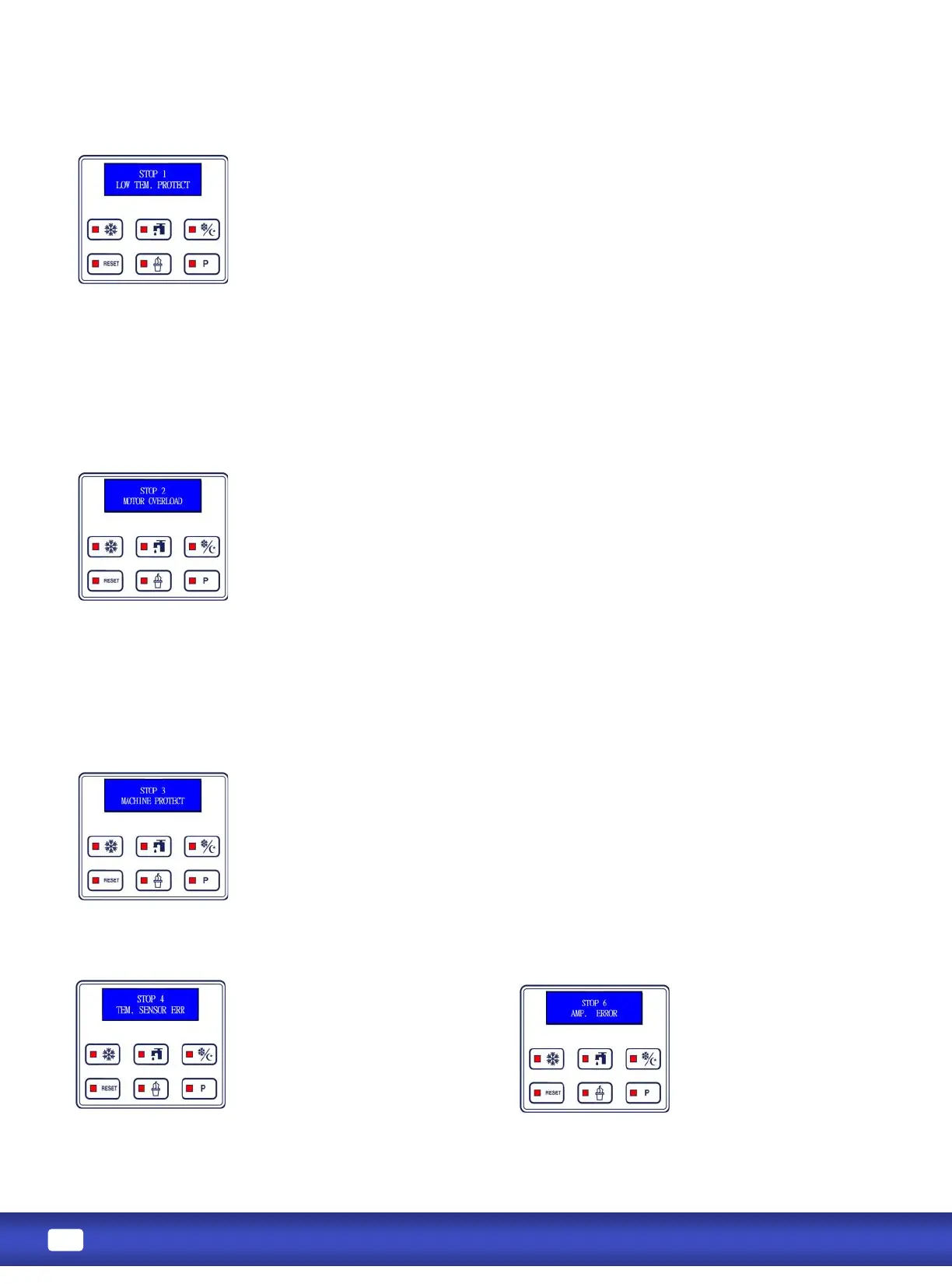

1. Viscosity adjustment is set

incorrectly.

2. Inadequate mix in hopper.

3. Improper mixing of product.

4. Air tube isn’t installed correctly.

5. Product is being drawn too

quickly.

1. Starved cylinder

2. Inadequate mix in hopper.

3. Improper mixing of product.

4. Air tube isn’t installed correctly.

5. Viscosity adjustment is set

incorrectly.

6. Air pump is not primed

Malfunconing temperature probe

Replace temperature probe.

1. Ensure hopper is at least half full.

2. Follow manufacturer instrucons for

mixing product; ensure correct mix raos.

3. Lower viscosity seng as required.

4. Ensure air tube isn’t clogged, allow

machine 2 to 5 seconds between servings.

5. (G) Clean air tube, ensure proper

orientaon.

6. (A) Check to make sure hand screws ght

on pump shell body and that shell gasket is

installed.

7. Prime air pump

8. Turn on DEFROST mode. (Page 15)

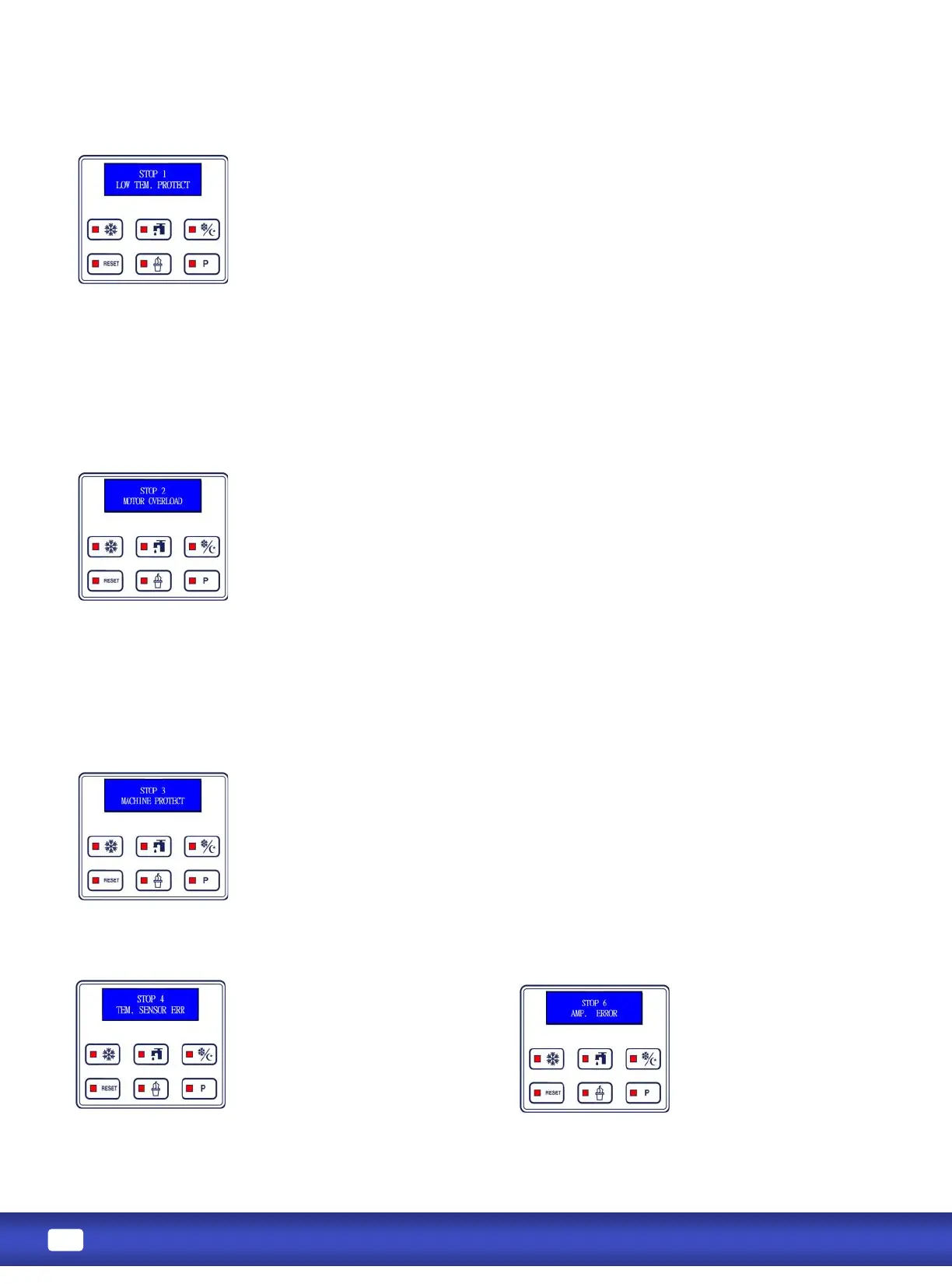

Malfunconing power board.

Replace power board.

1. Install the dispensing door.

2. Check and reinstall jumper on display

board.

1. Dispensing door is o.

2. Jumper on display board is

disconnected or loose.

1. Ensure hopper is at least half full.

2. Follow manufacturer instrucons for

mixing product; ensure correct mix raos.

3. Lower viscosity seng as required.

4. 5. Ensure air tube isn’t clogged, allow

machine 2 to 5 seconds between servings.

5. (G) Clean air tube, ensure proper

orientaon.

6. (A) Check to make sure hand screws ght

on pump shell body and that shell gasket is

installed.

7. Prime air pump

8. Turn on DEFROST mode. (Page 15)

Loading...

Loading...