21

9 CALIBRATION

9.1 Checking Calibration of the Y- and X-Axes

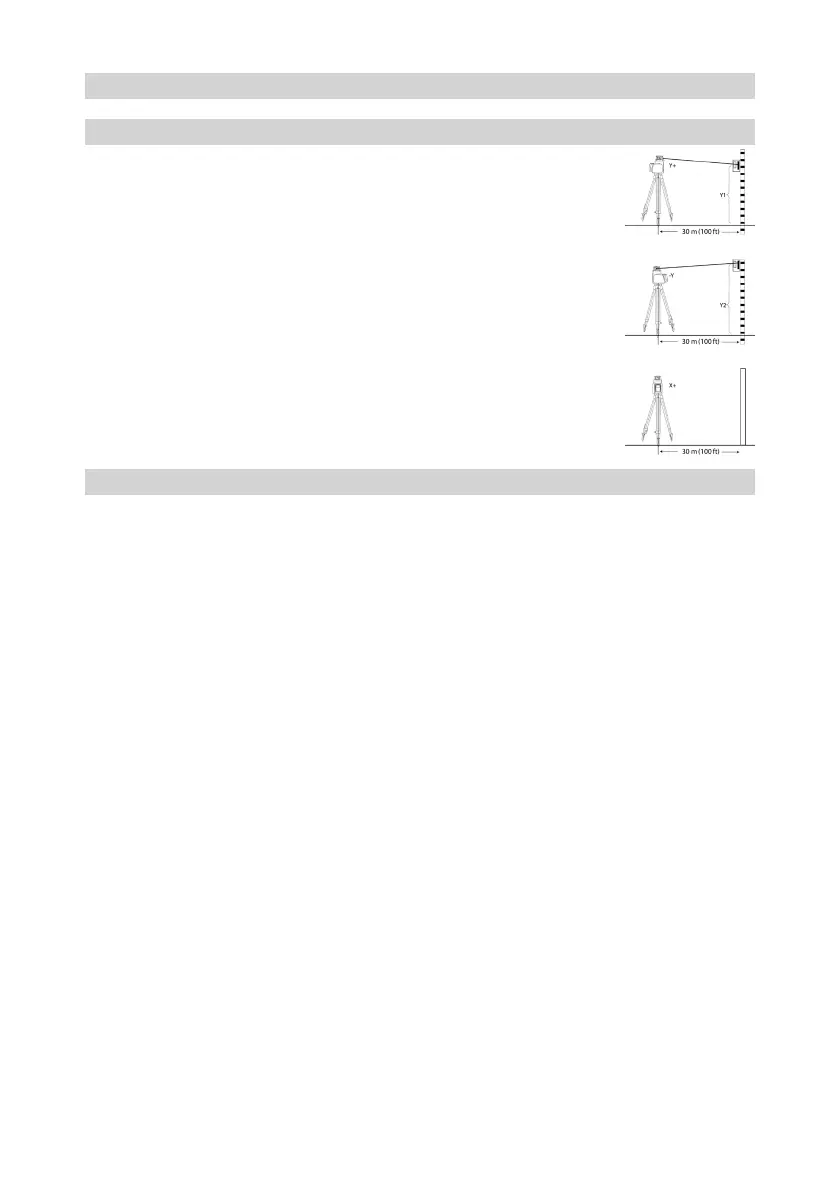

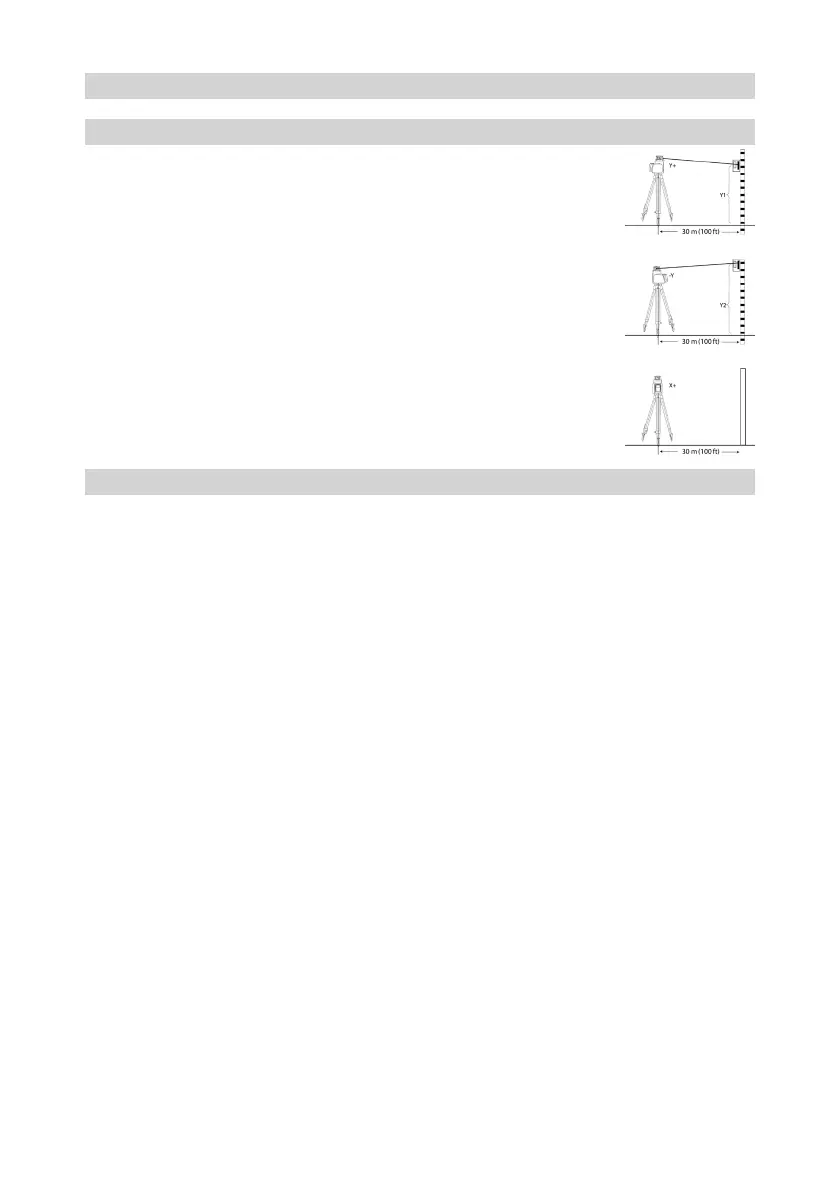

1. Set up the laser 30 m (100 ft) from a wall and allow it to level.

2. Setthegradeto0.000%inbothaxes.

3. Raise/lowerthereceiveruntilyougetanon-gradereadingforthe+Yaxis.Using

the on-grade marking notch as a reference, make a mark on the wall.

Note: Forincreasedprecision,usethesuperne-sensitivitysetting(1.0mm/1/16

in.) on the receiver.

4.Rotatethelaser180°(-Yaxistowardthewall)andallowthelasertore-level.

5.Raise/lowerthereceiveruntilyougetanon-gradereadingforthe–Y/axis.Usingthe

on-grade marking notch as a reference, make a mark on the wall.

6.Measurethedifferencebetweenthetwomarks.Iftheydiffermorethan3mmat30

m(1/8inchat100feet),thelaserneedscalibrating.

7.AftercheckingtheY-axis,rotatethelaser90°.Repeattheabovestartingwiththe

+Xaxisfacingthewall.

9.2 Checking Calibration of the Z-(vertical) Axis

To check vertical calibration, you need a plumb bob with at least 10m (30ft) of string.

1. Suspend the plumb bob in front of a house i.e., attached to a window frame whose window height is at least

10m (30ft).

2.Setupthelaserinverticalsothatthelaserbeamstrikesthereceiver’son-gradepositionatthetopofthestring.

3.Lookforanydeviationusingthereceiverfromthetopofthestringtothebottomofit.Ifthedeviationismore

than1mm(<1/16in.),theverticalaxisneedscalibrating.

Loading...

Loading...