Maintenance Waukesha Cherry-Burrell

Page 36 95-03009 10/2010

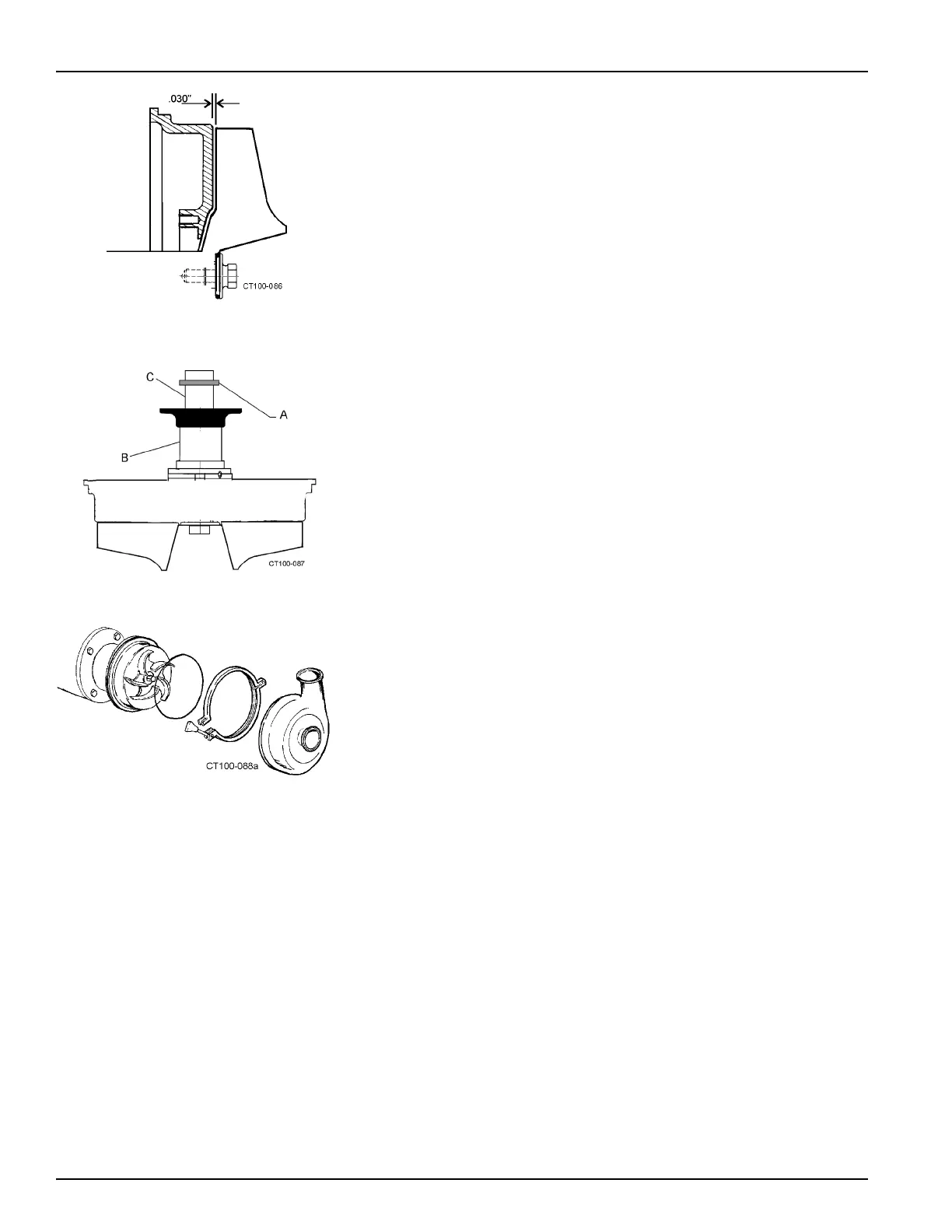

14. Check the space between the back of the impeller and the backplate

with a feeler gauge (0.030" nominal) while holding the backplate tight

against the bearing housing flange. (Any axial movement of the shaft

should not be added to the 0.030" nominal clearance) (Figure 33). If

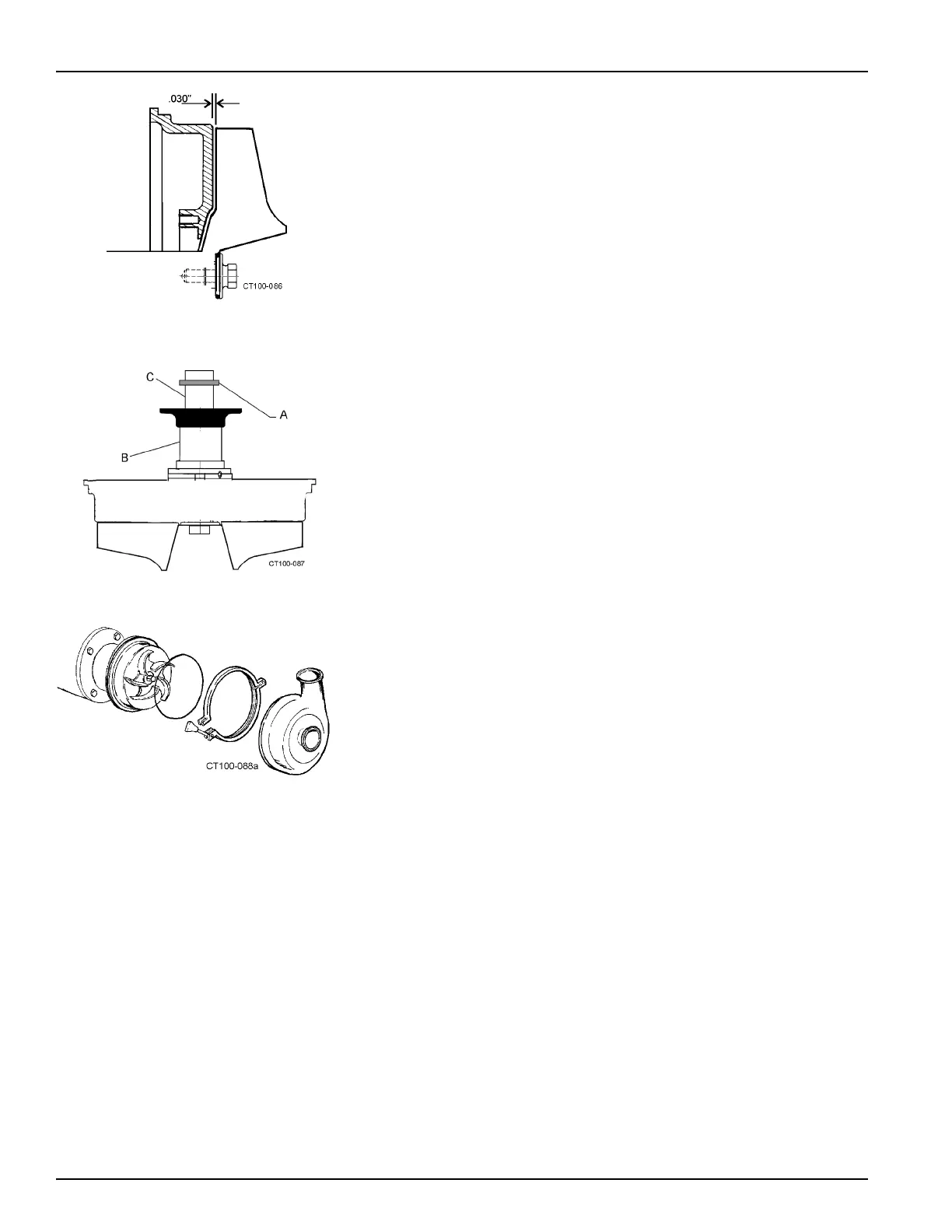

needed, change this clearance by adding or removing shims. Shims

(Figure 34, item A) are added on the drive shaft (Figure 34, item C)

behind the impeller shaft (Figure 34, item B).

15. Confirm the operating clearances b

y

clamping the casing to the bear-

ing housing flange and rotating the shaft/impeller manually to be sure

the

impeller does not touch the casing or backplate.

16. When the proper shim pack is confirmed, remove the casing, impel-

ler, and backplate, leaving the shim pack on the shaft.

17. Remove the backplate/impeller assembly and apply anti-seize or

equal compound to the motor shaft and install the key.

NOTE: Always re

place the o-rings and L-gasket when reassembling the

pump. If the area behind these seals becomes soiled, contact WCB Appli-

cation Engineering for a specific cleaning and sanitizing procedure vali-

dated to remove bacteria.

18. Install the casing o-ring on the backplate and clamp the casing in

pla

c

e (Figure 35).

NOTE: Rotate the impeller manually to ensure it does not rub on the

ba

ckplate or casing.

Figure 33 - Clearance Between Impeller

and Backplate

Figure 34 - Locations of Shims

Figure 35 - Install Casing

Loading...

Loading...