Installation Waukesha Cherry-Burrell

Page 26 95-03080 12/2010

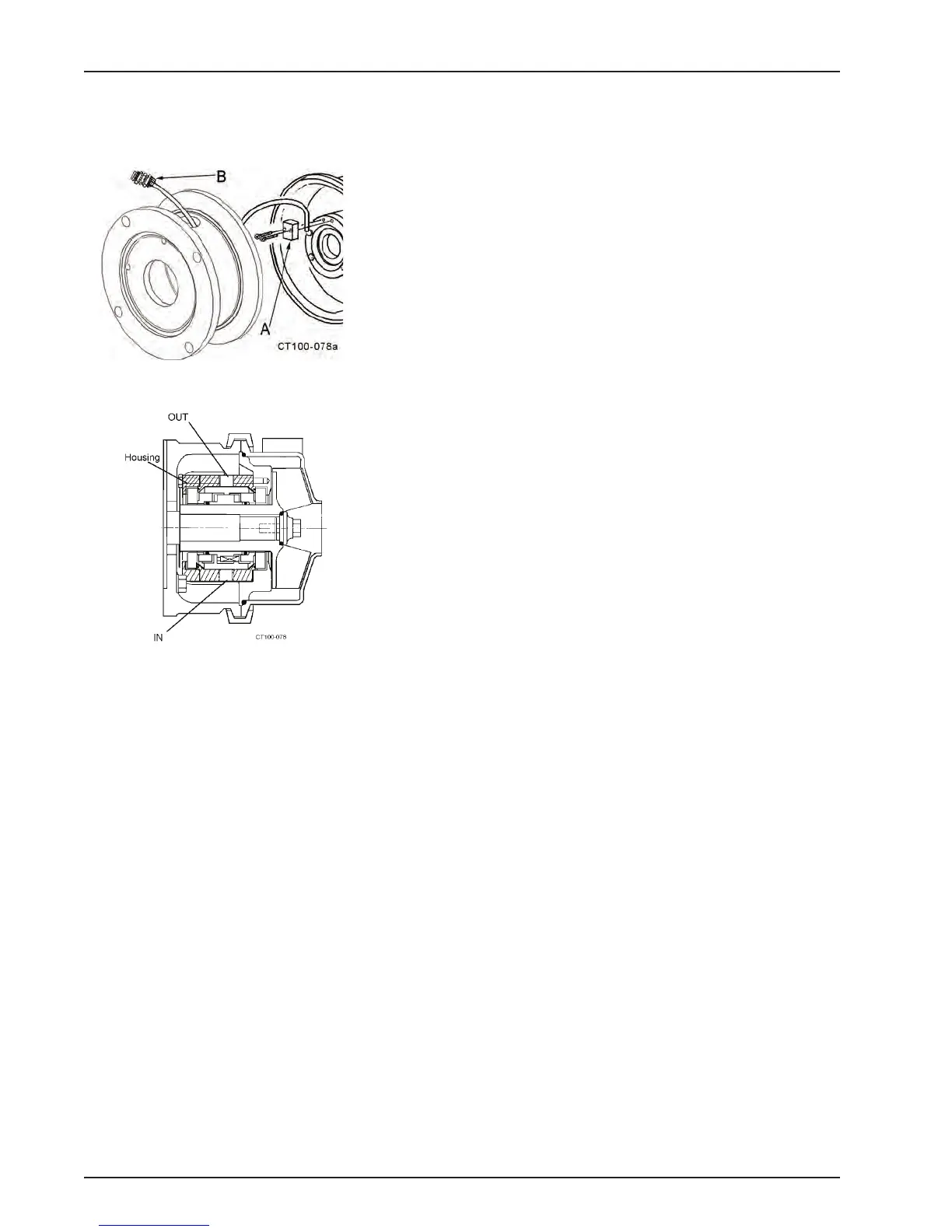

Flush Seal Option When this option is ordered, a fitting assembly (Figure 20, item A)

is supplied for directing a flow of water onto the backplate/seal

area.

• The water cascade block must be above the seal on the

assembled backplate to flow water onto the seal face.

• The connection (Figure 20, item B) is 1/4 inch O.D. tubing.

• The required flow is approximately 5 U.S. gallons per hour.

• The recommended water supply is cool and filtered. If the

pr

oduct solidifies at cool temperature, warm or hot water can

be used.

NOTE: To prevent hose contact with the rotating shaft and seal

parts during operation, pull any excess hose to the outside of the

seal guard.

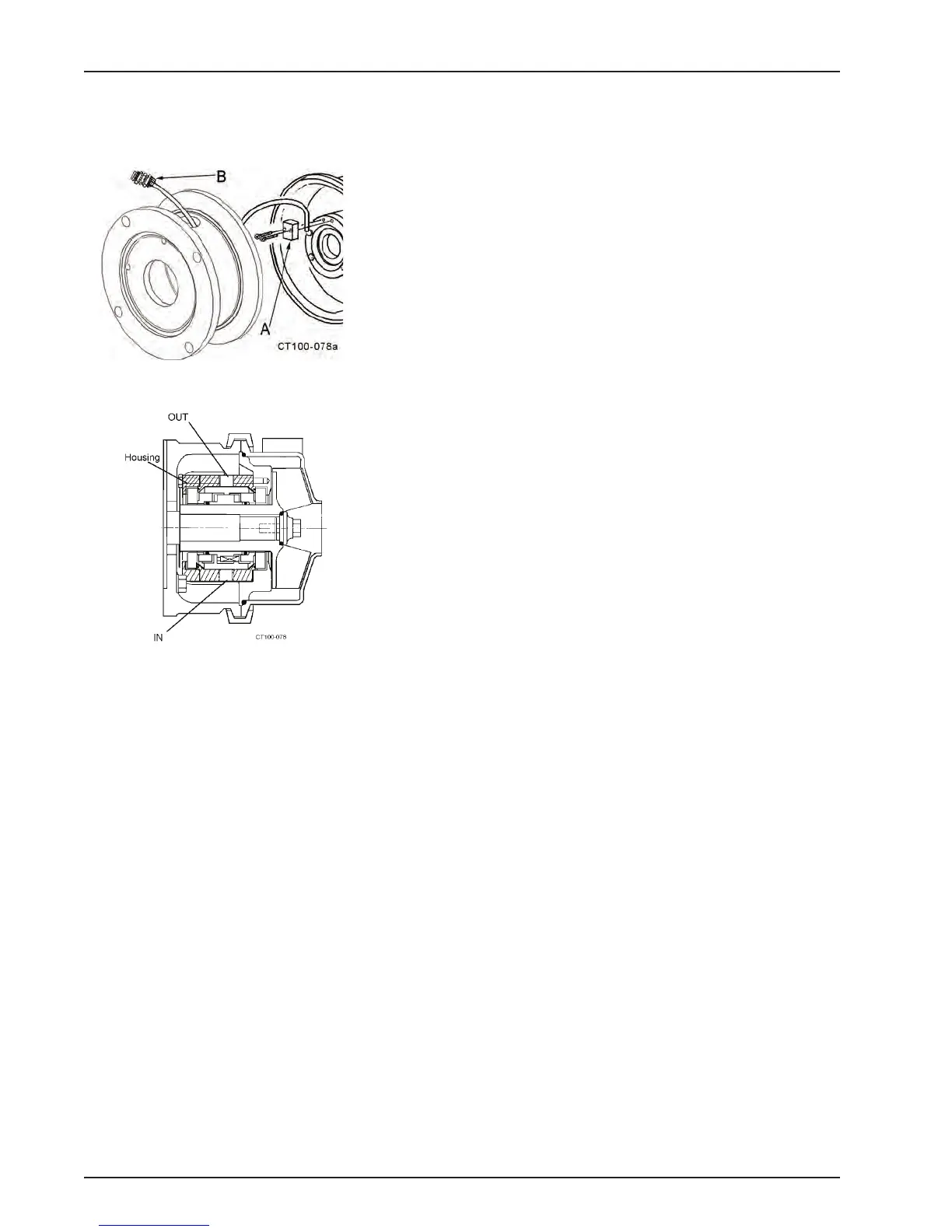

Type 4 Seal (Double mechanical with flush)

Attach the seal flush supply to the bottom 1/4-inch pipe threaded

hole in the flush housing. The drain tubing attached to the top hole

allows moderate pressure to be supplied to the seals and allows

continuous flooding. See Figure 21.

Before First Startup Clean Pump and Piping

Disassemble pump and clean all product contact parts and seal

parts prior to first operation. Follow instructions in the “Cleaning

Safety Procedures” on page 27 and “Routine Maintenance” on

page 28. The pump should be thoroughly cleaned of any materi-

als which could have accumulated during installation.

Figure 20 - Cascade System Installation

Figure 21 - Type 4 Flush Housing

Loading...

Loading...