Waukesha Cherry-Burrell Installation

12/2010 95-03080 Page 23

Installation Unpack all parts of your equipment and inspect for damages that

may have occurred during shipping. Report any damage to the

carrier.

All ports are covered at the factory to keep out foreign objects

during transit. If the covers are missing or damaged, remove the

pump cover and thoroughly inspect the fluid head. Be sure the

pump head is clean and free of foreign material before rotating

shaft.

Pump Location Address the following considerations when determining a location

for the installation of your pump:

• Locate the pump as near as is practical to the liquid supply.

• Keep the supply piping short and straight to keep the pump

supplied with liquid and prevent damaging cavitation.

• The pump should be accessible for service and inspection

during operation.

• The motor must be protected from flooding.

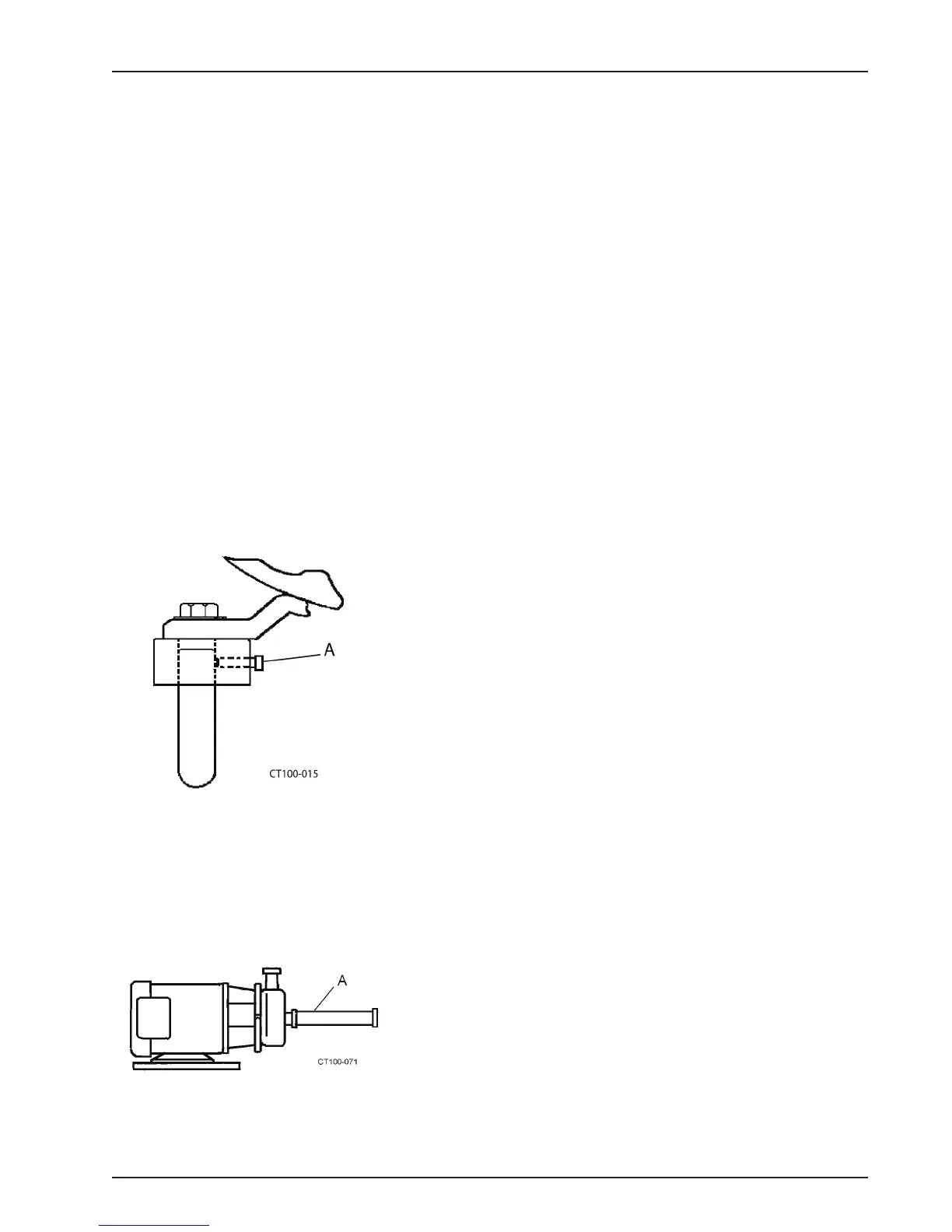

Pump Leveling Level the pump by loosening the set screws (Figure 13, item A) to

adjust the length of the legs.

Supply and Discharge

Piping/Valves

Address the following considerations when determining supply/

discharge piping and valve installation of your pump.

1. Use a line size equal to or larger than the connection size on

the pump, especially the inlet supply line.

2. Keep the supply line as short and straight as possible and

use as few elbows, valves or other types of restrictions as

possible. Avoid up and down rises which will trap air.

3. Be certain that all joints in the suction line are well-sealed to

prevent air leaks.

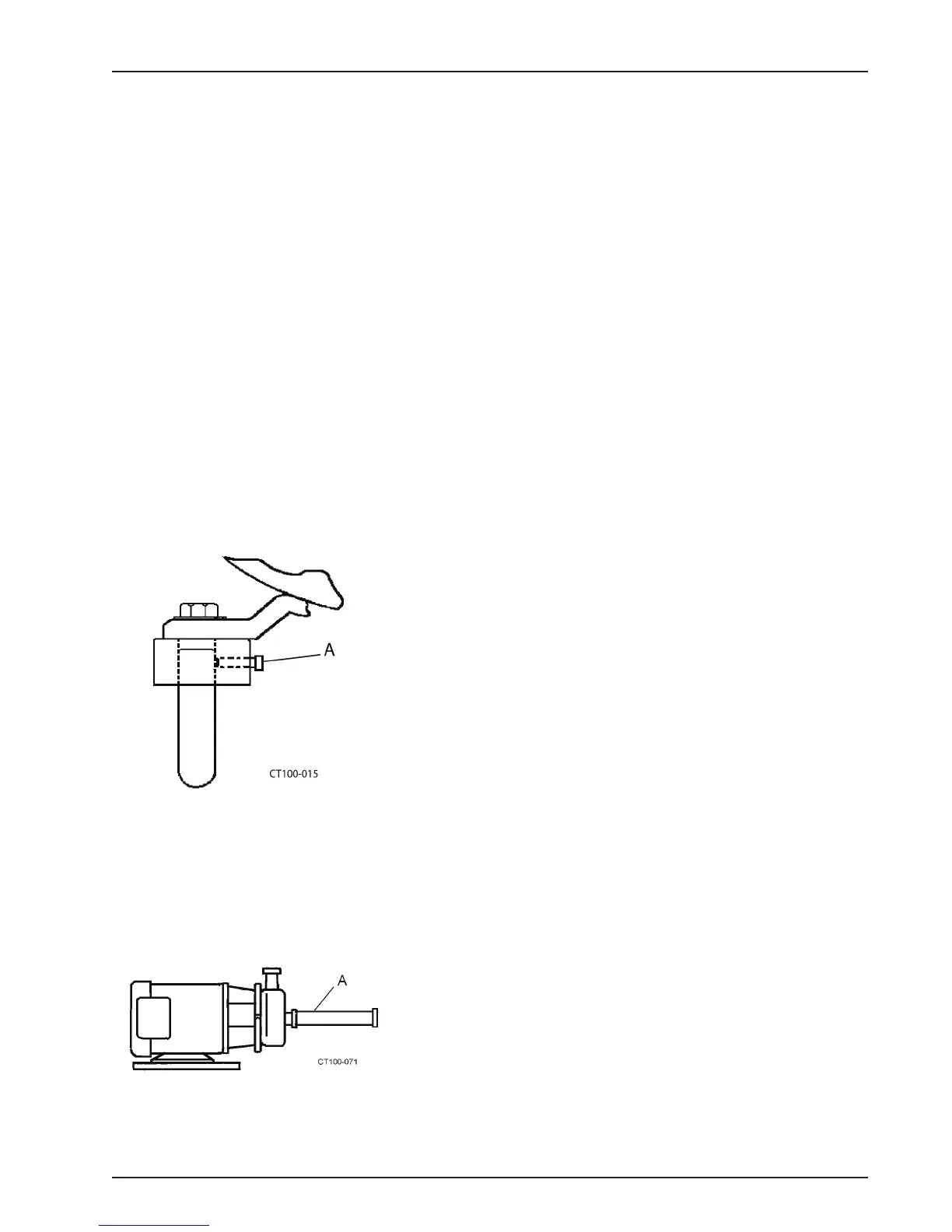

4. Maintain a straight length of pipe (Figure 14, item A) at least 8

diameters long at the pump inlet.

Figure 13 - Leveling Leg Set Screw

Location

Figure 14 - Straight Pipe Length

Loading...

Loading...