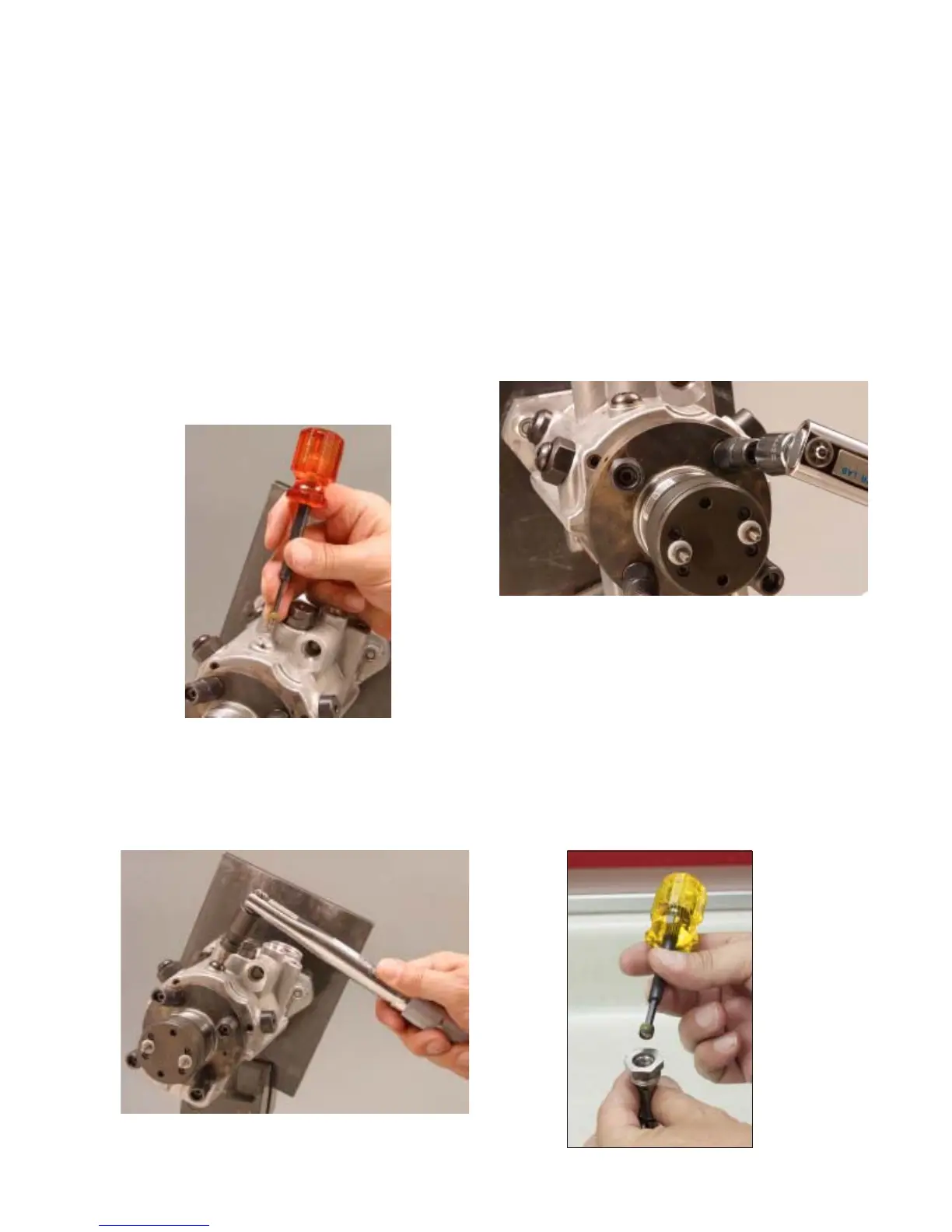

Step 54 Install the vent wire assembly into the

hydraulic head. Tighten to 25-30 lbf-inches (3-

3.5 N-m) using a 1/8” hex bit. Five different vent

wire assemblies are available to control the

volume of return oil flow from the pump. Refer

to the individual specification for part numbers.

During reassembly it is recommended to rein-

stall the same vent wire that was removed dur-

ing disassembly and then during calibration a

different number wire can be installed as nec-

essary to achieve the specified return fuel flow.

Vent wire assemblies are marked with numbers

0 – 5 on the ends to identify them. The higher

the number the less fuel flow through the vent

wire assembly.

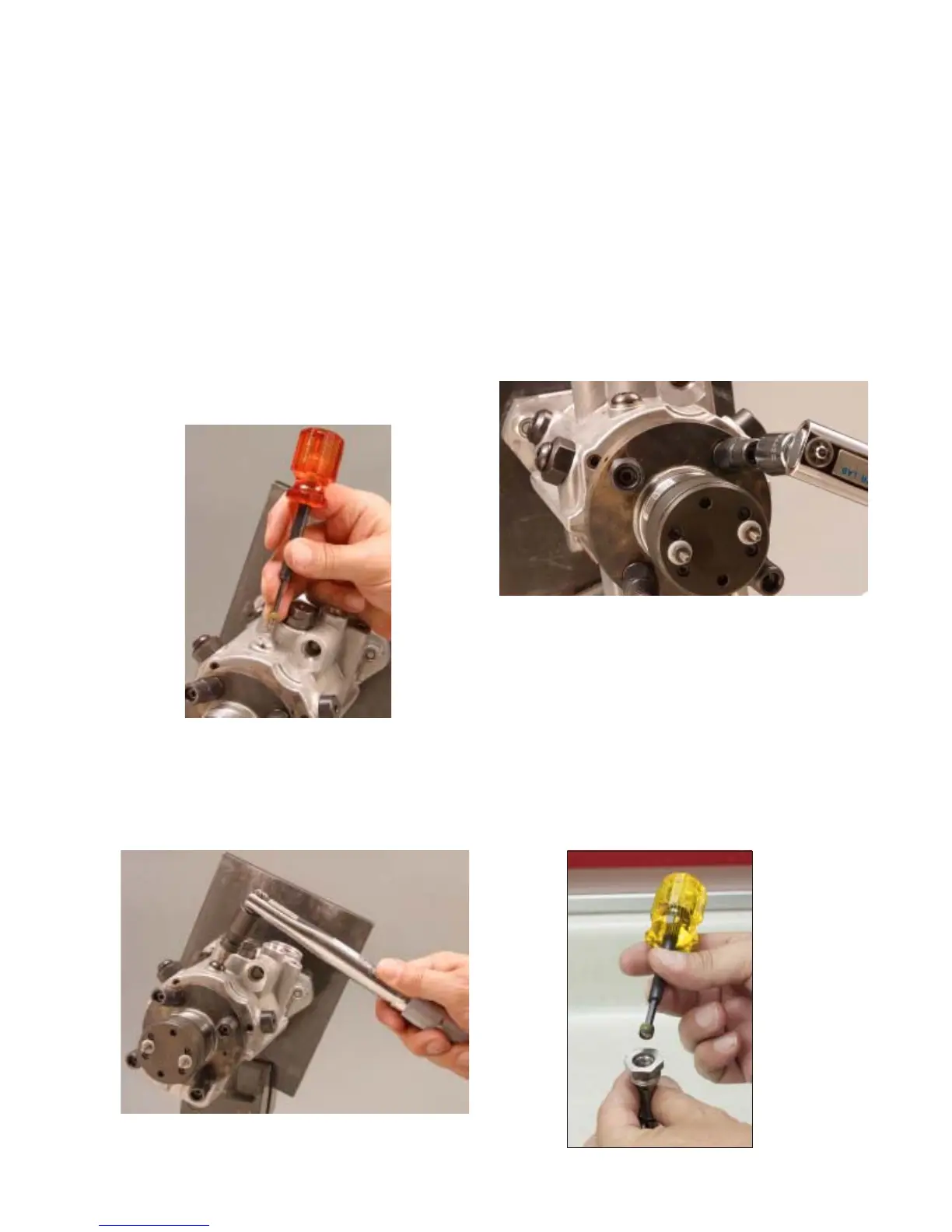

Step 55 Assemble a new sealing washer to

the vent wire assembly access screw. Install the

screw into the housing and tighten to 60-70 lbf-

inches (7-8 N-m) using a T40IPR bit.

Step 56 Install a new seal on the transfer

pump tap screw and install the plug into the head

locking screw hand tight. The screw will be tight-

ened to 110-130 lbf-inches (12.5-15 N-m) us-

ing a T40 bit during calibration.

Step 57 Install the snubber plates and springs

into all the fuel line connectors.

Step 58 Dip the snubber valve retaining

screws in clean calibrating fluid and install one

in each fuel line connector. Tighten each screw

to 40-60 lbf-inches (4.5-6.8 N-m) using a 1/8”

hex bit.

Step 59 Insert the transfer pump regulator pis-

ton, spring and adjusting plug into the transfer

pump regulator assembly. Thread the adjusting

plug until the top of the plug is just below the fuel

flow passages. NOTE: It may be necessary to

hold the regulator assembly in a vise by its

hex head in order to install the screw due to

the thread locking compound on the plug.

43

Fig. 4.54

Fig. 4.55

Fig. 4.58

Fig. 4.59

Loading...

Loading...