INSTALLATION

Mounting

www.stiebel-eltron.com WPF basic | 19

9.2 Electrical installation

In accordance with VDE 0298-4, use the following cable cross-sec-

tions subject to their fuse protection:

Fuse/MCB

rating

Assignment Cable cross-section

C 16 A Compressor

(three phase)

2.5 mm²

B 16 A

Electric emergency/

booster heater (BH)

(three phase)

2.5 mm²

1.5 mm² with only two live cores and

routing on a wall or in an electrical con-

duit on a wall.

C 16 A

Compressor

WPF 5 S basic

(single phase)

1.5 mm² for open routing. Note the type

of routing!

2.5 mm² for routing through a

wall. Note the type of routing!

C 25 A

Compressor

WPF 7 S basic /

WPF 10 S basic

(single phase)

4.0 mm² for open routing. Note the type

of routing!

6.0 mm² for routing through a

wall. Note the type of routing!

C 35 A

Electric emergency/

booster heater (BH)

(single phase)

4.0 mm² when routing a multi core line

on a wall or in an electrical conduit on

a wall.

6.0 mm² for routing through a

wall. Note the type of routing!

B 16 A Control circuit fuse

(three phase)

1.5 mm²

C 16 A Control circuit fuse

(single phase)

1.5 mm²

The electrical data is given in the “Specification” chapter.

Provide separate fuses for the two power circuits of the appliance

and the control unit.

9.3 Buffer cylinder

Note

In combination with the WPF 13 basic and the WPF 16

basic, it is absolutely imperative to use a buffer cylinder.

A buffer cylinder is recommended to ensure trouble-free appliance

operation.

The buffer cylinder provides hydraulic separation of the flow rates

in the heat pump circuit and the heating circuit.

When operating without a buffer cylinder, observe the details

specified in the chapter “Minimum flow rate without buffer

cylinder”.

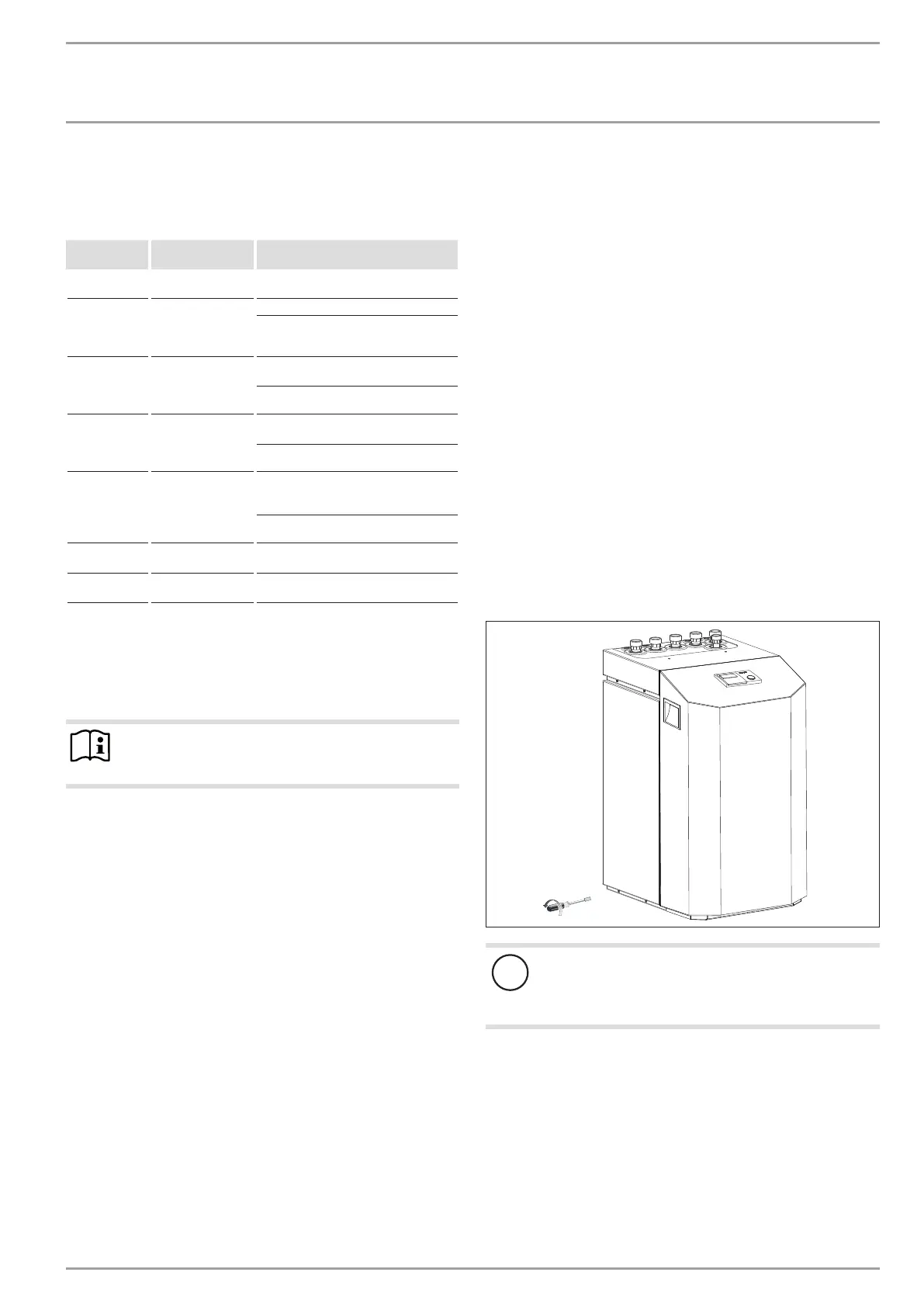

10. Mounting

10.1 Handling

Transport the appliance in its packaging to protect it against

damage.

Protect the appliance against heavy impact during transport.

- Only allow the appliance to be tilted during transport for a

short time to one of its longitudinal sides.

The longer the appliance is tilted, the greater the distribution

of refrigerant oil in the system.

- Storage and transport at temperatures below - 20 °C and in

excess of + 50 °C are not permissible.

10.2 Positioning

Remove the packaging film and the top and side EPS

padding.

Tilt the appliance backwards slightly and remove it from the

pallet.

Position the appliance on the prepared substrate.

Observe the minimum clearances (see chapter “Dimensions

and connection”).

Remove the six screws from the appliance plinth, and set

down the casing onto the floor.

6x

26�03�01�1573

!

Appliance damage

The casing must stand on the floor free from the refrig-

eration unit. D. h. That means, the six plinth screws must

not be refitted.

Loading...

Loading...