INSTALLATION

Mounting

20 | WPF basic www.stiebel-eltron.com

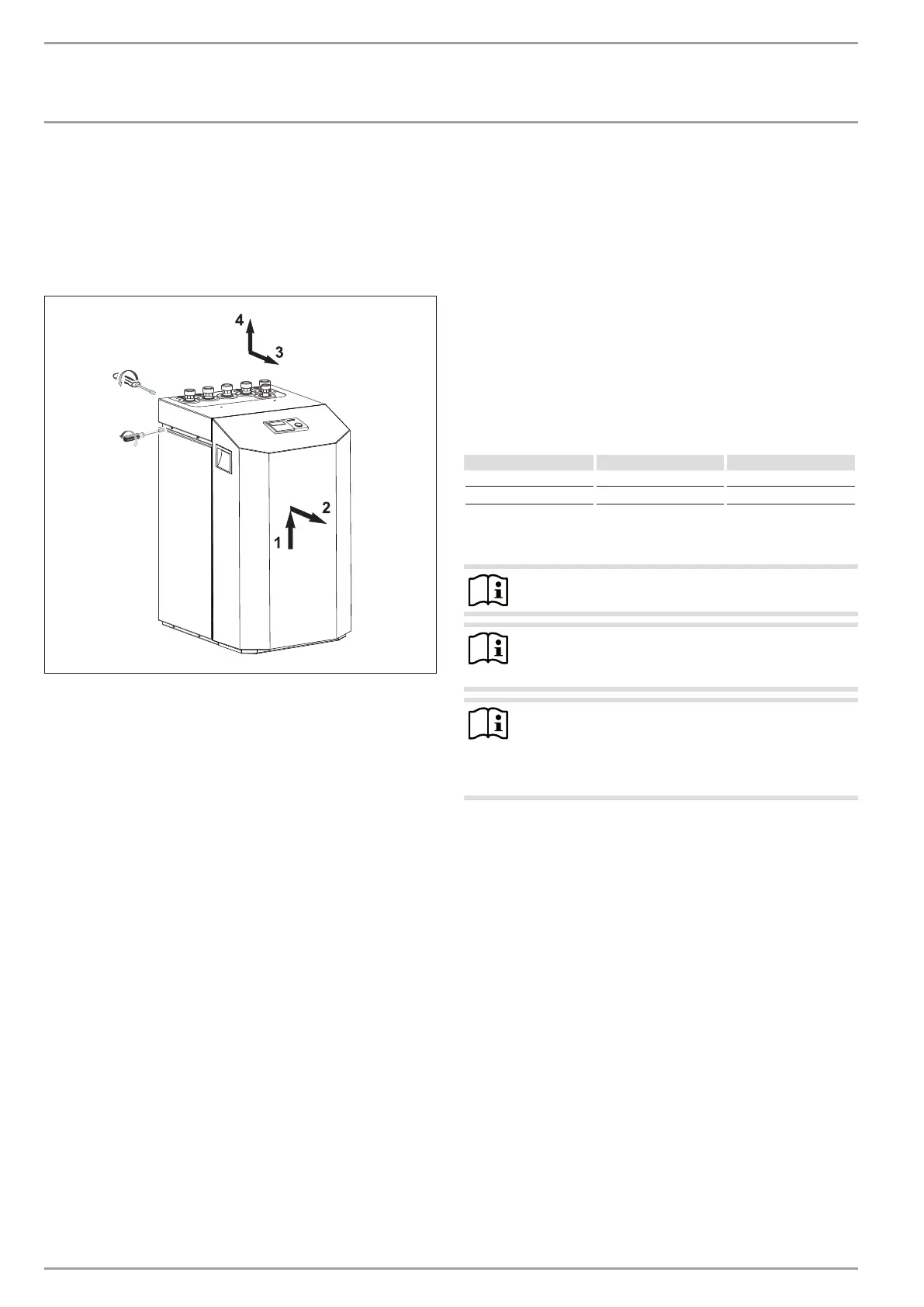

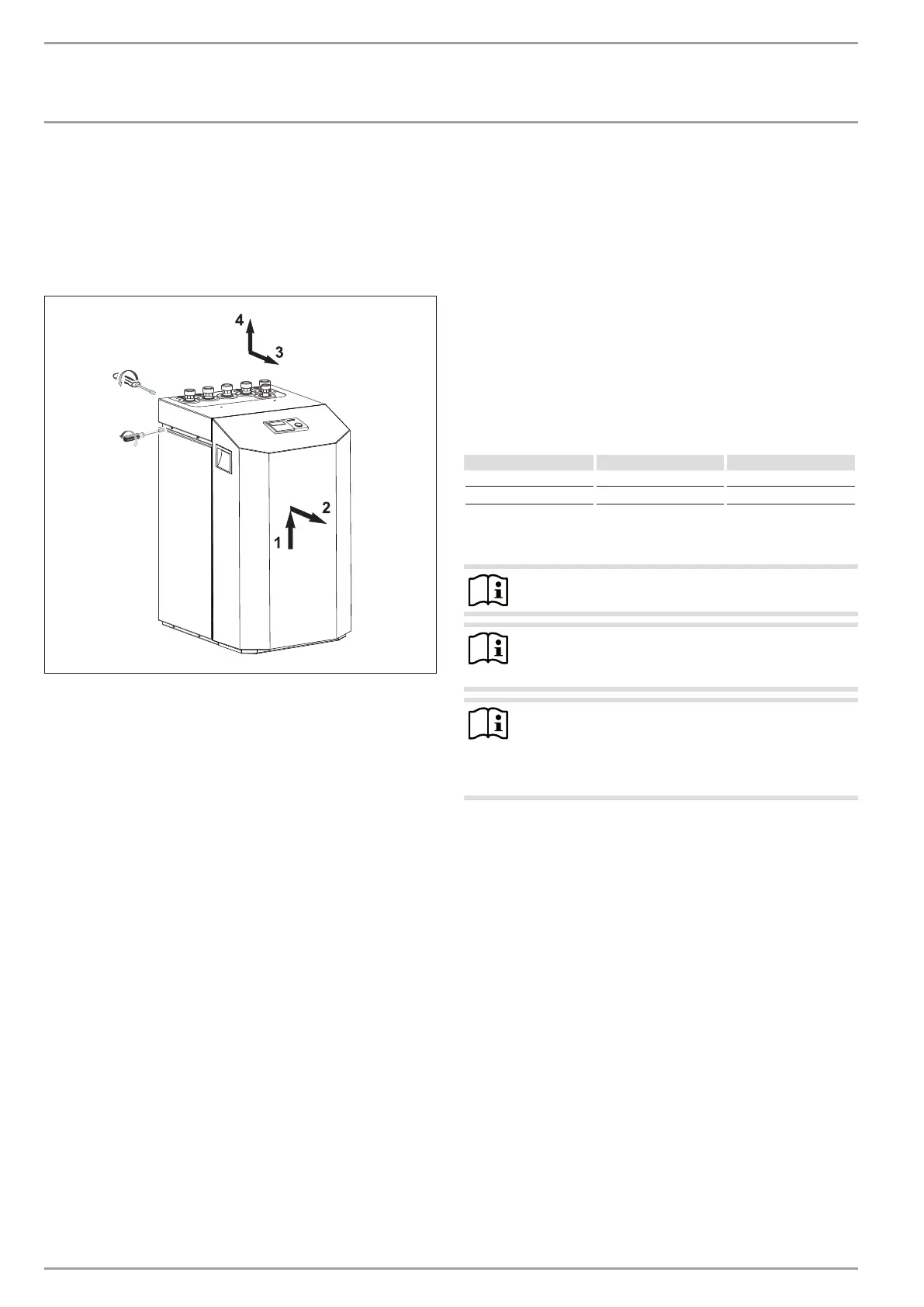

10.3 Removing the casing panels

When removing the front cover ensure, that the cables, which

connect the heat pump manager with the control panel, are not

torn off.

The same applies to the earth connection which electrically con-

nects the front cover to the casing.

2x

4x

26�03�01�1574

10.4 Installing the heat source system

Design the heat source system for the ground source heat pump

in accordance with the technical guides.

10.4.1 Permitted brine:

- Heat transfer medium as concentrate on an ethylene glycol

base, part no: 231109

- Heat transfer medium as concentrate on an ethylene glycol

base, part no: 161696

10.4.2 Circulation pump and required flow rate

Use a circulation pump with compound-filled windings to supply

the brine, to prevent an earth short circuit through condensate in

the electrical part of the pump (cold water version).

Size the circulation pump in accordance with the system-specific

conditions, h. i.e. nominal flow rate and pressure drop must be

taken into consideration (see “Specification”).

An adequate flow rate must be safeguarded at every possible

brine temperature, i.e.:

Nominal flow rate at a brine temperature of 0°C with a tolerance

of +10%.

10.4.3 Connection and filling with brine

Prior to connecting the heat pump, check the heat source circuit

for possible leaks, and flush thoroughly.

Calculate the volume of the heat source circuit. The brine volume

of the heat pump under operating conditions can be found in the

data table (see chapter “Specification”).

The overall volume is equal to the required amount of brine made

by mixing undiluted ethylene glycol and water. The chloride con-

tent of the water must not exceed 300 ppm.

Mixing ratio

The brine concentration varies when using a ground collector or

a geothermal probe as a heat source.

The mixing ratio can be found in the table below.

Ethylene glycol Water

Geothermal probe 25 % 75 %

Geothermal collector 33 % 67 %

Charging the brine circuit

Note

The WPF S series does not have a brine pressure switch.

Note

Insulate the brine lines with diffusion-proof thermal

insulation.

Note

The brine pressure switch is bridged to the power supply

utility contact at the factory.

To activate the brine pressure switch, remove the

jumper.

The brine/water heat pump is equipped with a brine pressure

switch in the brine circuit. The brine pressure switch prevents

brine getting into the ground if there is a leak in the brine circuit.

If the pressure in the brine circuit falls below 0.7bar, the brine

pressure switch turns the heat pump off. In order for the heat

pump to be enabled again, the pressure must be raised to at least

1.5bar while the heat pump is on standby.

To prevent the brine pressure switch turning the heat pump off

when there is no leak, charge the heat source side of the heat

pump during installation with a minimum pressure of >1.5bar.

Fill the system according to the following curve.

Loading...

Loading...