INSTALLATION

Troubleshooting

www.stiebel-eltron.com WPF basic | 43

13. Troubleshooting

13.1 Fault display

Faults/errors in the system or in the heat pump are indicated on

the display. All parameters required for an in-depth system analy-

sis can be checked under the system menu items COMMISSIONING

and TEMPERATURES. For troubleshooting, analyse all available

parameters before opening the heat pump control panel.

The controller will not indicate that the booster heater high limit

safety cut-out has responded. The high limit safety cut-out can be

reset by your contractor through pressing the reset button. The

high limit safety cut-out response is generally caused by air in the

heating circuit or an inadequate heating flow rate.

Check the heating flow rate and ventilate the heating system.

13.1.1 Heat pump-specific or hardware faults

All faults are displayed.

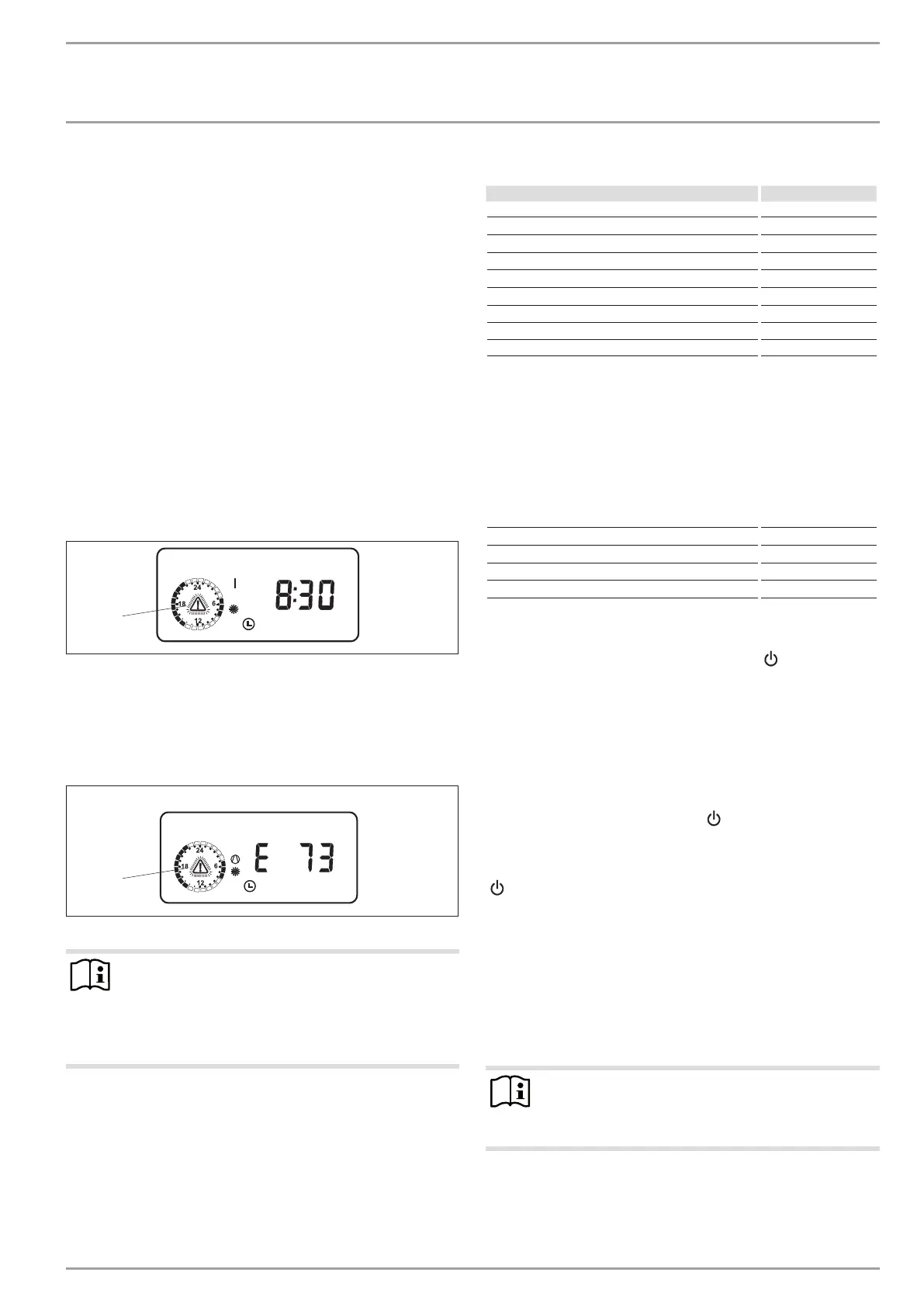

Example: High pressure fault

26�03�01�1063

1

HP SENSOR MAX

1 Fault message (flashing)

All faults cause the heat pump to shut down. The idle period will

be set and, with the exception of MAX HOT GAS T, ALl faults are

written to the fault list.

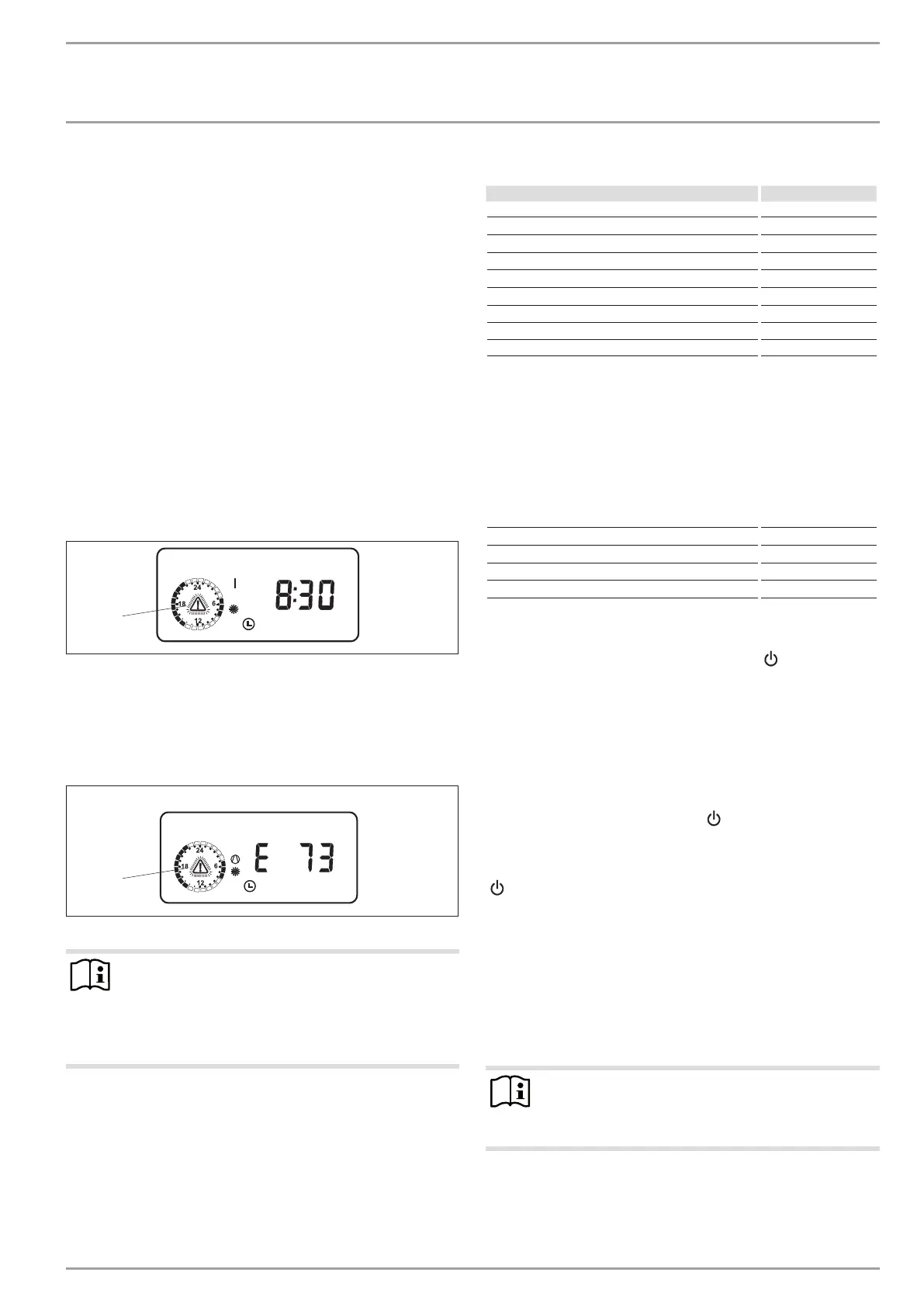

13.1.2 Sensor break = sensor fault

26�03�01�1064

1

SENSOR BROKEN

1 Fault message (flashing)

Note

This fault code refers to temperature sensors that can be

called up under the parameter TEMPERATURES. These

faults are not entered into the fault list. The system will

not be shut down. The display message will extinguish

immediately after the fault has been removed.

Observe the list under system parameter TEMPERATURES.

Sensor Fault code

Outside temperature E 75

Remote control E 80

Actual DHW temperature E 76

Actual heat pump return temperature (H1) E 73

Actual mixer flow temperature (H2) E 70

Actual heat pump flow temperature E 72

Actual source flow temperature E 71

High pressure sensor E 130

LP sensor E 128

13.1.3 Fault message with DCO enabled

In connection with the dial-up connection controller DCO enabled,

the sensor faults listed above result in the transmission of the error

codes (E75 to E130) by SMS to the authorised recipient.

In addition, the following fault codes are transmitted as text mes-

sage:

Contactor stuck E 20

No power E 21

Low pressure E 22

HIGH PRESSURE E 23

HP sensor max E 24

13.1.4 Checking brine pressure

Check brine pressure if the heat pump is blocked for more

than three hours (standby symbol flashes [

]).

Check the brine pipe for leaks.

Remedy any leaks.

Recharge the system (see chapter “Installation/ Installation/

Installing the heat source system/ Connection and brine

charging/ Charging the brine circuit”).

13.1.5 The heat pump does not run

The heat pump is in standby mode [

]

Remedy: Change to automatic mode

The power supply has been blocked; the standby symbol flashes

[

]

Remedy: Wait; the heat pump restarts automatically at the end

of the blocking time.

There is no heat demand

Remedy: System parameter TEMPERATURES, check temperatures

and compare the actual and set temperatures.

Possibly incorrect fuse rating

Remedy: See Specification

Note

Under these circumstances, you can only restart the heat

pump after the fault has been removed and the heat

pump has been reset (parameter WPM RESET).

Additional parameters available for system analysis:

Quick start:

Check the heat pump compressor by implementing a quick start

Loading...

Loading...