38 MS 201, MS 201 C, MS 201 T, MS 201 TC

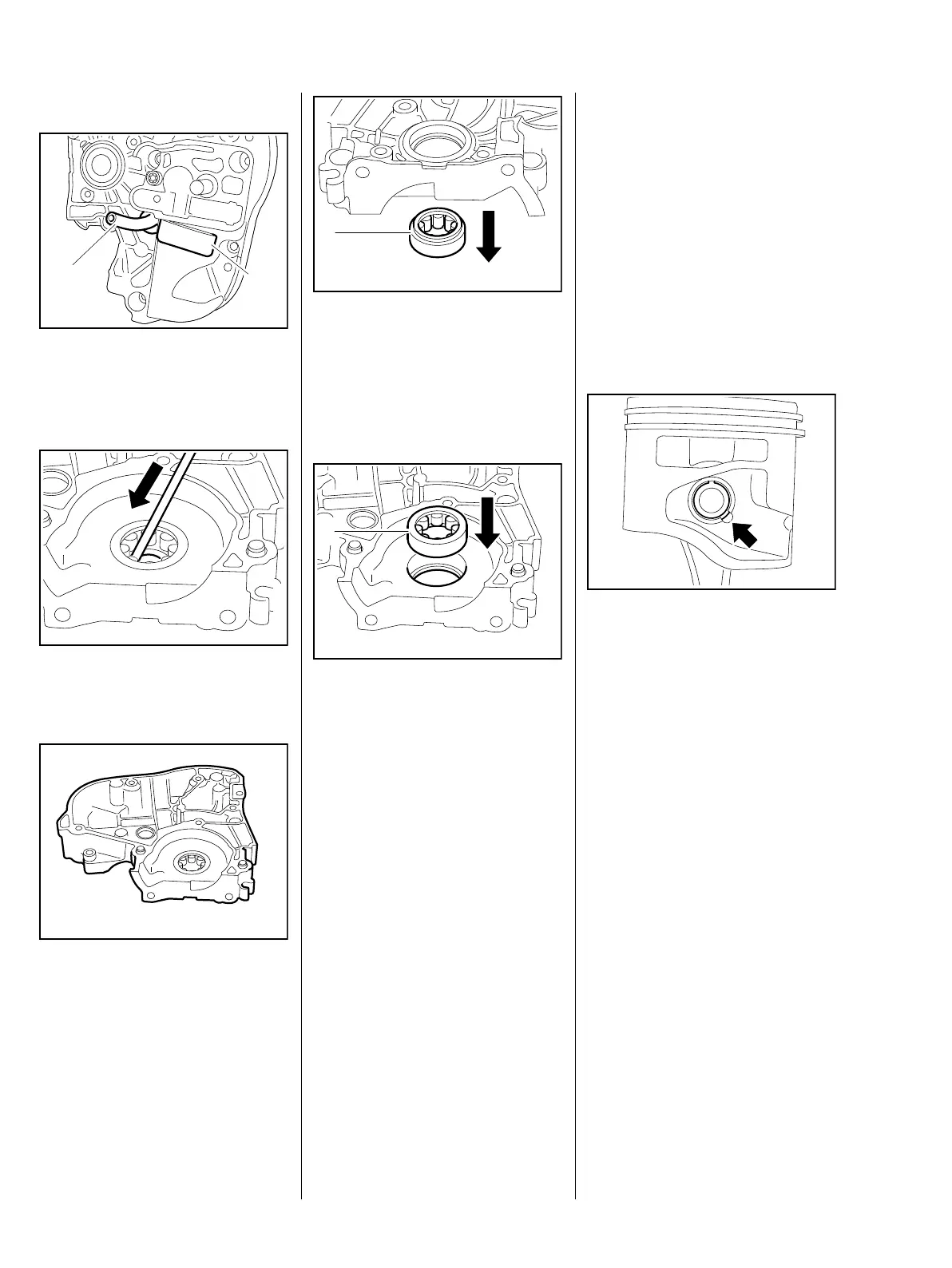

Clutch side of crankcase

: Pry out the bumper strip (1).

: Pull out the oil suction hose (2).

: Use a suitable punch to carefully

drive out the oil seal.

: Check and clean the crankcase

or replace if necessary, b 14

If this half of the crankcase is in

order, install a new roller bearing.

7013RA492 TG

1

2

7013RA493 TG7013RA494 TG

– Heat area of bearing seat to

approx. 160 °C (320 °F).

The roller bearing (1) drops out as

soon as this temperature is

reached.

– Heat area of bearing seat to

approx. 160 °C (320 °F).

– Position the roller bearing so that

the nylon ring faces outwards.

: Press the roller bearing (1) fully

home.

This operation must be carried out

quickly because the bearing

absorbs heat and begins to expand.

– Install the crankshaft and

assembly the two halves of the

crankcase, b 6.5

7013RA495 TG

1

7013RA496 TG

1

– Install the oil seals, b 6.3

– Reassemble all other parts in the

reverse sequence.

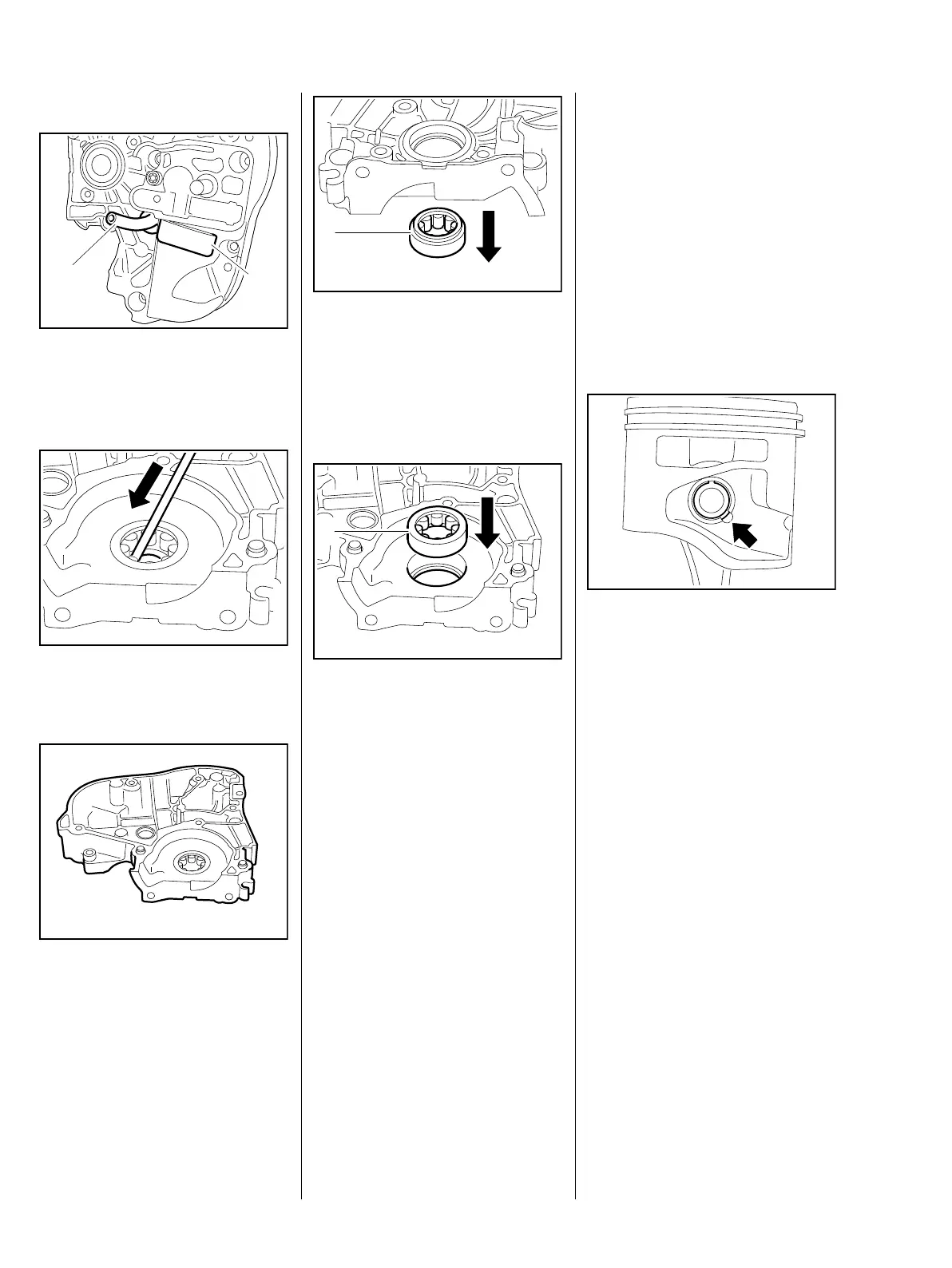

6.6 Piston

– Remove the cylinder, b 6.4

The piston has only one snap ring. It

is fitted at the side facing the

straight crankshaft stub.

: Use a suitable tool to grip the

snap ring at the recess (arrow)

and ease it out.

7013RA497 TG

Loading...

Loading...