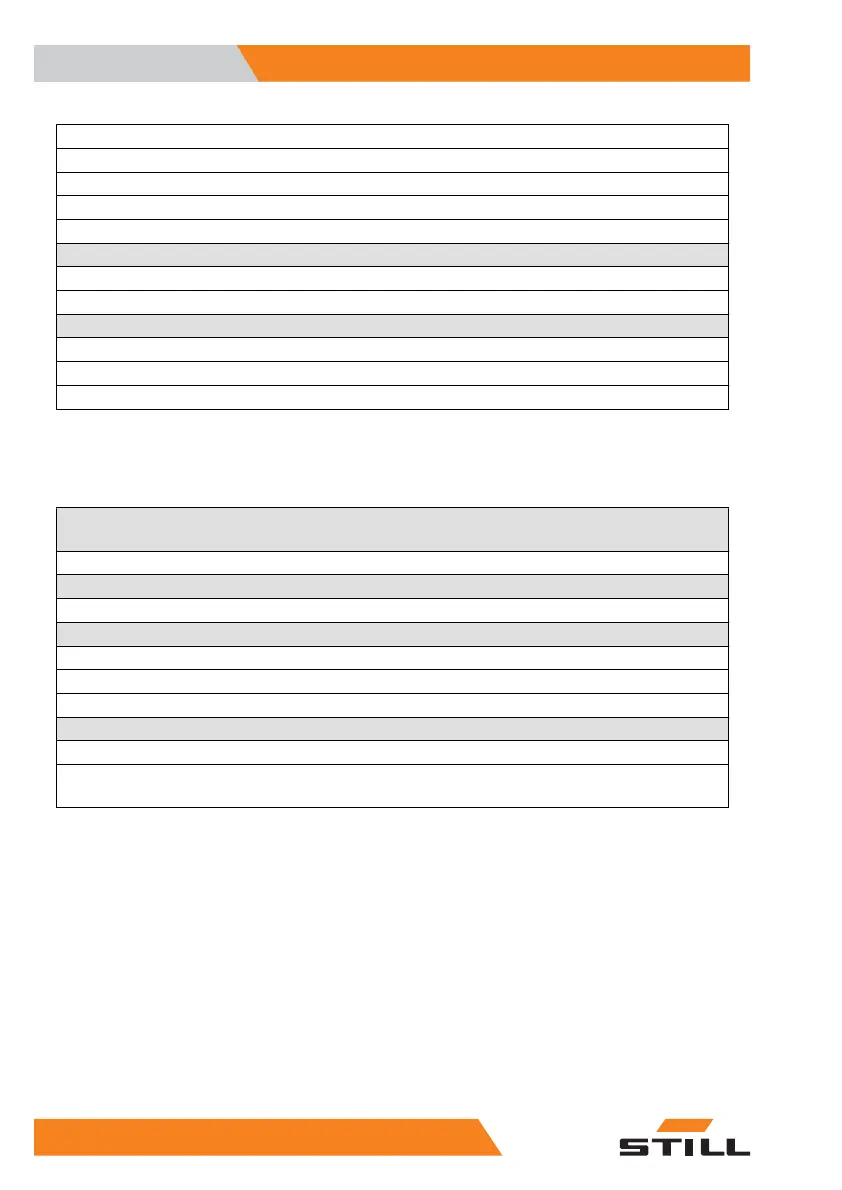

Checking the condition of the front and rear brake shoes

Checking the drive axle rubber shock mounts

Checking the drive axle suspension bushes

Checking the steering stops (wear and tightness)

Checking and adjusting the battery compartment door latch

Electrical/electronic equipment

Checking the battery acid level and electrolyte density

Checking the traction controller

Optional equipment

Checking the oil level in the Liftrunner system equipment

Checking the condition of the motor brushes for the Liftrunner system equipment

Checking the condition of the mounting for the Opportunity Charging equipment

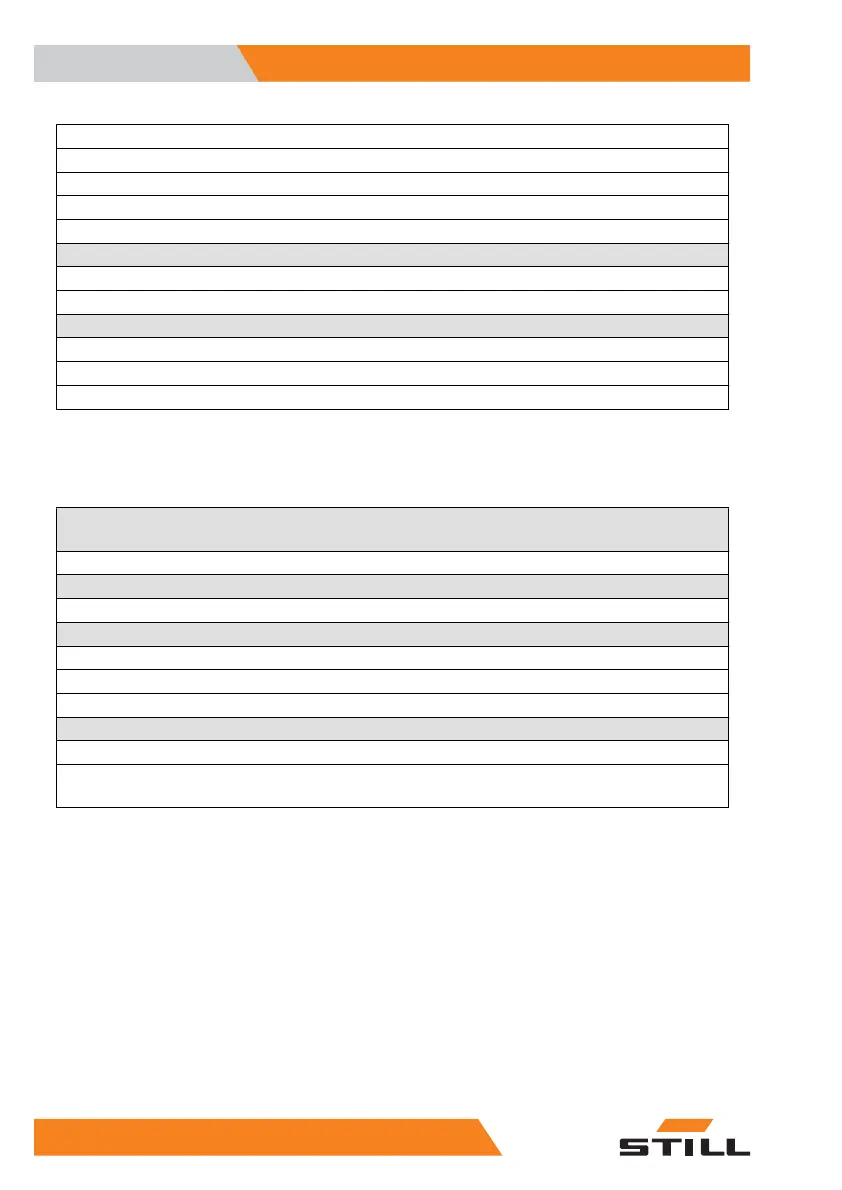

3000-hour/two-year maintenance plan

Depending on the application, environmental conditions and driving style, the following proce-

dures should be carried out every 3000, 6000 and 9000 hours

Information

Carry out all 1000-hour maintenance work

Chassis, bodywork and fittings

Changing the brake fluid

Checking the electromagnetic brake

Draining and filling the drive axle

Optional equipment

Draining then refilling the Liftrunner system equipment with engine oil

Visually checking the condition of the air filter for the agitation pump (on board charger). Clean-

ing the filter with water if necessary.

Maintenance

5

3000-hour/two-year maintenance plan

126 1191 801 15 51 EN - 02/2021 - 10

Loading...

Loading...