25

S

7. Maintenance

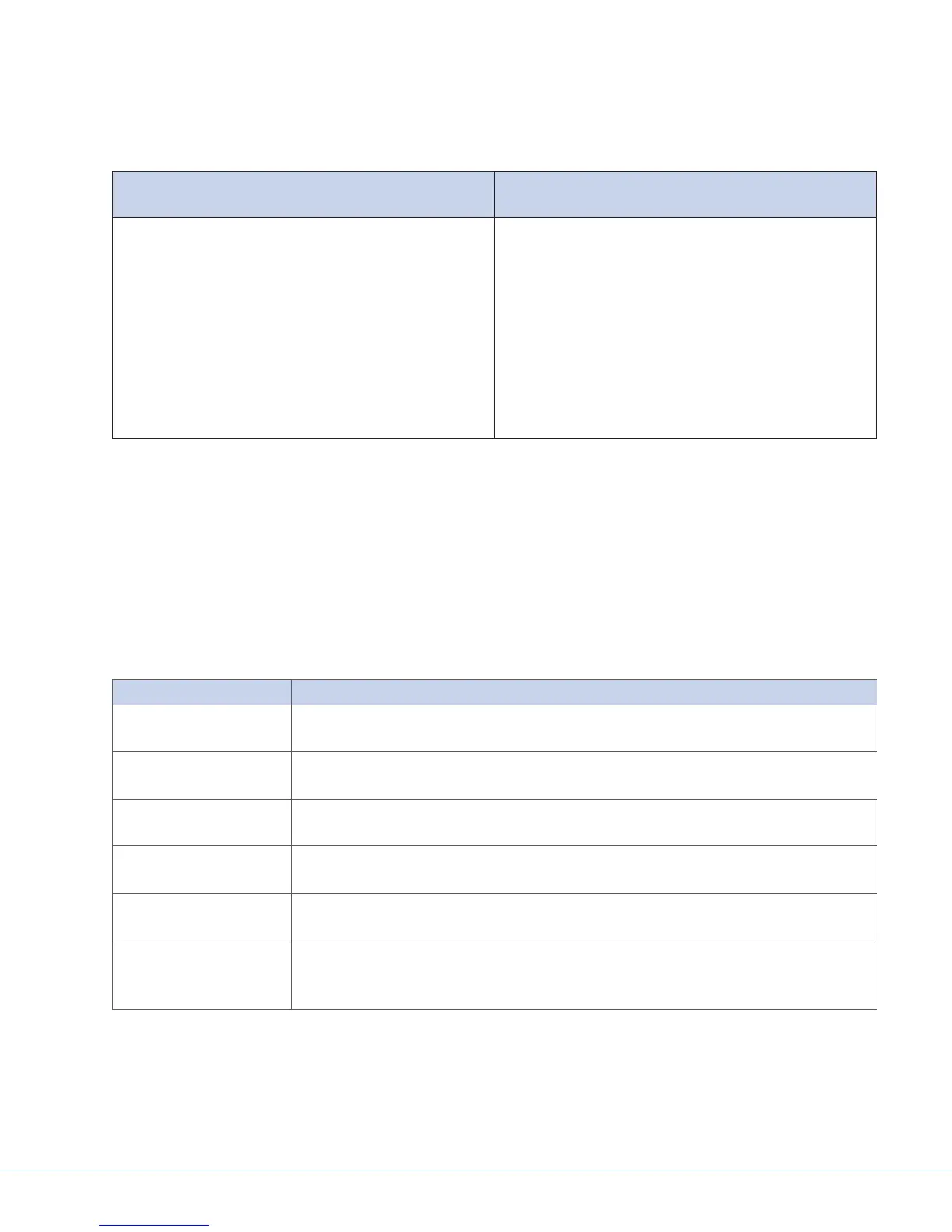

7.1 Maintenance Schedule

Hospital Personnel Responsibility

Every 6 Months

Stryker Personnel Responsibility

Every Other Year*

• Damage to paint

• Cracks on plastic parts

• Deformation of the system

• Loose parts

• M3 Safety Segment cover screw

• Properly tighten brake screws

• Tighten thumb screws on handle or in-light

camera

• Inspect face glass for damage (cracks or chips)

• Inspect for haze inside the face glass

• Inspect all exposed screws and torque to

specication (e.g. drop tube screws, sterile

handle assembly, etc.)

• Inspect for drifting. Adjust brake screws

accordingly

• Measure light intensity according to

specications in user manual

• Ensure wall control functions (if applicable)

* Please contact Stryker Technical Support or your Stryker Representative to schedule your preven tative

maintenance service.

Contact Stryker Communications in case of:

• Faults

• Damage

• Service Needs

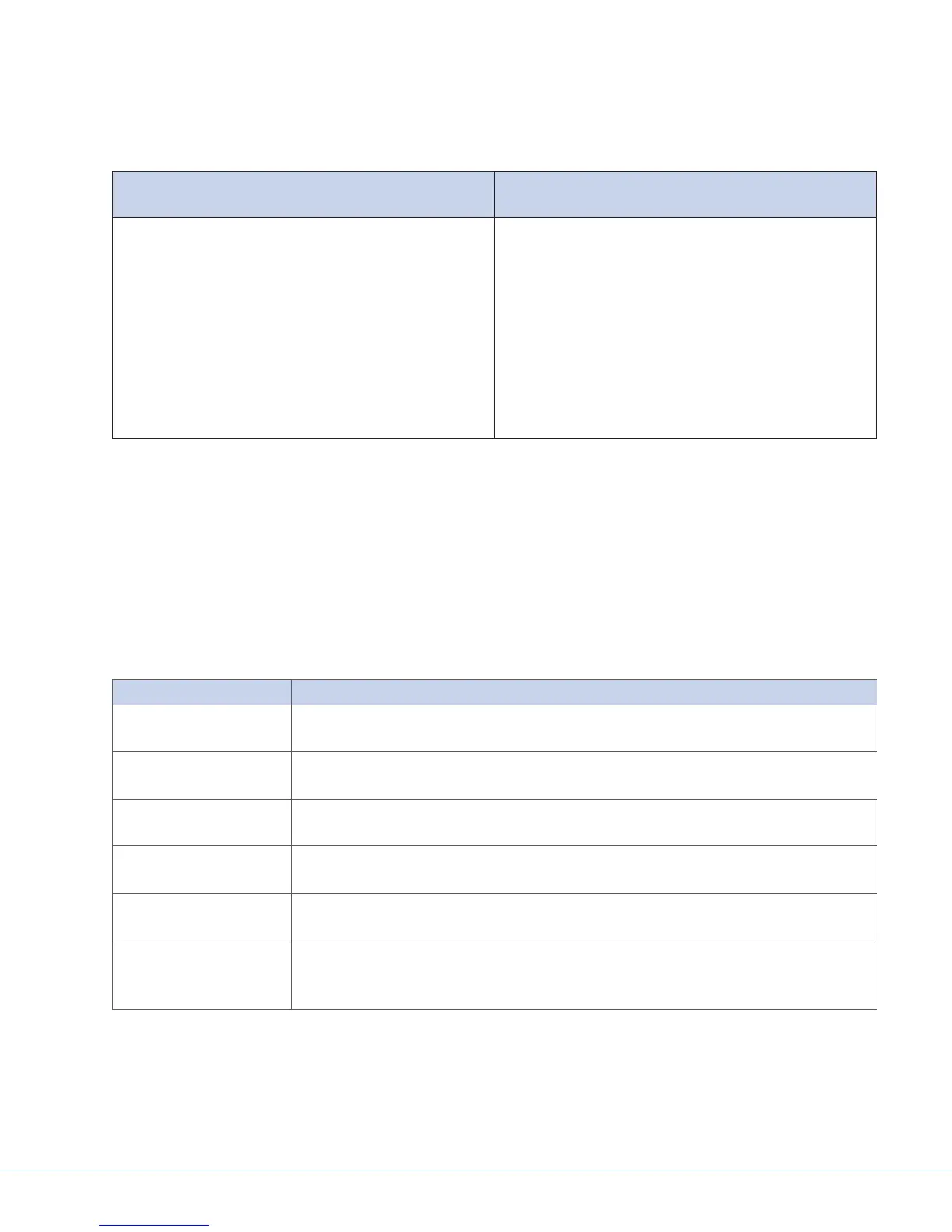

7.2 Quick Reference for Brake Screw Adjustment

Behavior Adjustment

Extension Arm drifts

left or right

Tighten the two brake screws at the shoulder joint of the Extension Arm

Extension Arm is

dicult to move

Loosen the two brake screws at the shoulder joint of the Extension Arm

Spring Arm drifts left

or right

Tighten the two brake screws at the elbow joint of the Extension Arm

Spring Arm is dicult

to move left or right

Loosen the two brake screws at the elbow joint of the Extension Arm

Spring Arm drifts up or

down

Adjust the Spring Arm tension near the elbow joint of the Spring Arm

Cardanic Suspension is

dicult to rotate

Loosen the brake screw of the Spring Arm where it meets the Cardanic

Suspension (the cover for this brake screw will have to be removed before the

brake screw can be adjusted)

Loading...

Loading...