27

CCaauuttiioonn

66

HOW TO REPAIR THE MACHINE

The machine is set to be the best condition at the factory. Do not make any discrete adjustments on the

machine and replace genuine parts approved by the company only.

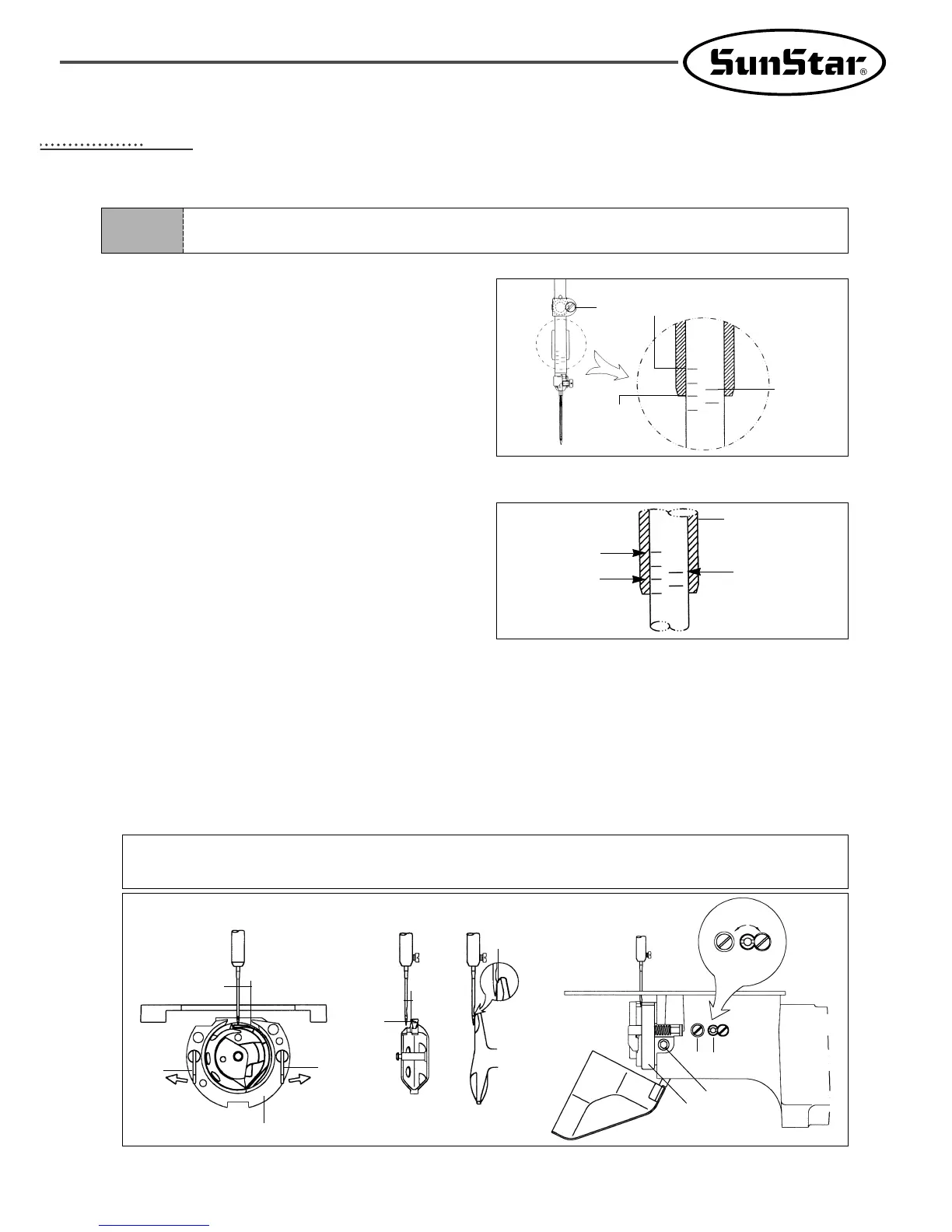

1) Adjusting the Height of the Needle Bar

When the needle bar is at its lowest position, unfasten

the needle bar holder screw ①. Adjust the desired

height by making the specified upper carving line fit in

with the needle bar bushing. Then, tighten the needle

bar holder screw back on firmly.

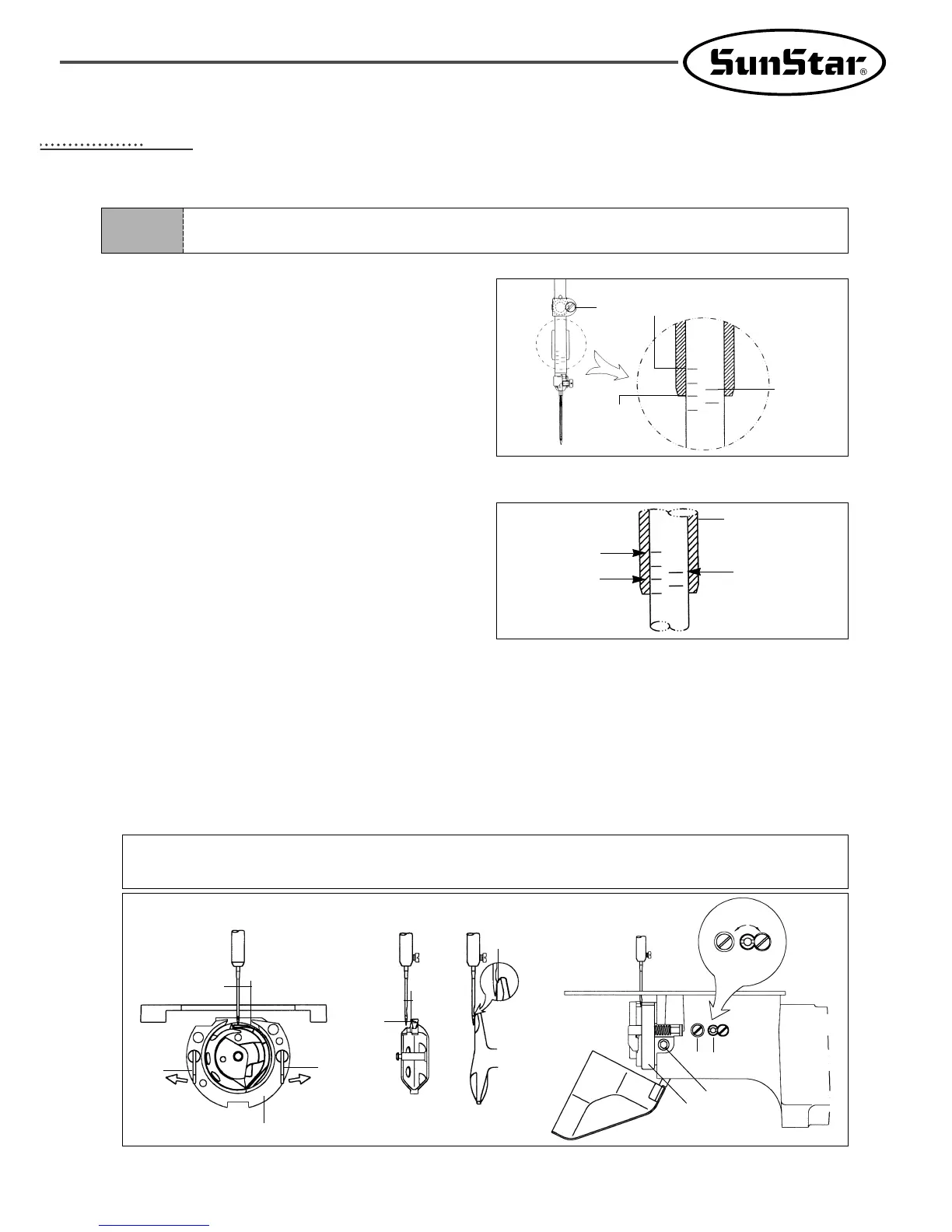

2) Adjusting the Needle and the Shuttle

B. After unfastening the shuttle drive screw ①, open the inner hook pressure bar ② left to right and remove the

shuttle Race ring ③ from the (large) shuttle ④.

C. Make the shuttle hook point accord with the center of the needle. And make the needle and the front face of the

shuttle drive connect each other to prevent the needle from curving. Then, tighten the drive screw ① firmly.

D. After unfastening the (large) shuttle screw ⑤, turn the large hook adjustment shaft ⑥ to the left to right and adjust

the (large) shuttle ④ so that the needle and the shuttle hook point is 0.05~0.1mm apart from each other.

E. After adjusting the (large) shuttle ④ in place, adjust the rotary direction of the (large) shuttle ④ so the needle and

the (large) shuttle ④ is 7.5mm apart from each other. Then, tighten the (large) shuttle screw ①.

A. Have the lower carving line for the needle that is

applied when the needle bar goes up fit in with the

lower side of the needle bar bushing as shown in the

picture.

[ Fig. 35 ]

[ Caution ]

For safety, make sure all the screws are tightened firmly after adjusting the (large) shuttle.

[ Fig. 33 ]

[ Fig. 34 ]

①

DP×5

DP×17

#21 and

Below

DP×17

#22 and

Above

Needle Bar

Lower Bushing

DP×5

DP×17

#21 and

Below

DP×17

#22 and Above

7.5mm

②

②

⑥

③

→

→

0.05~0.1mm

→

→

⑤

①

④

0mm

Loading...

Loading...