34

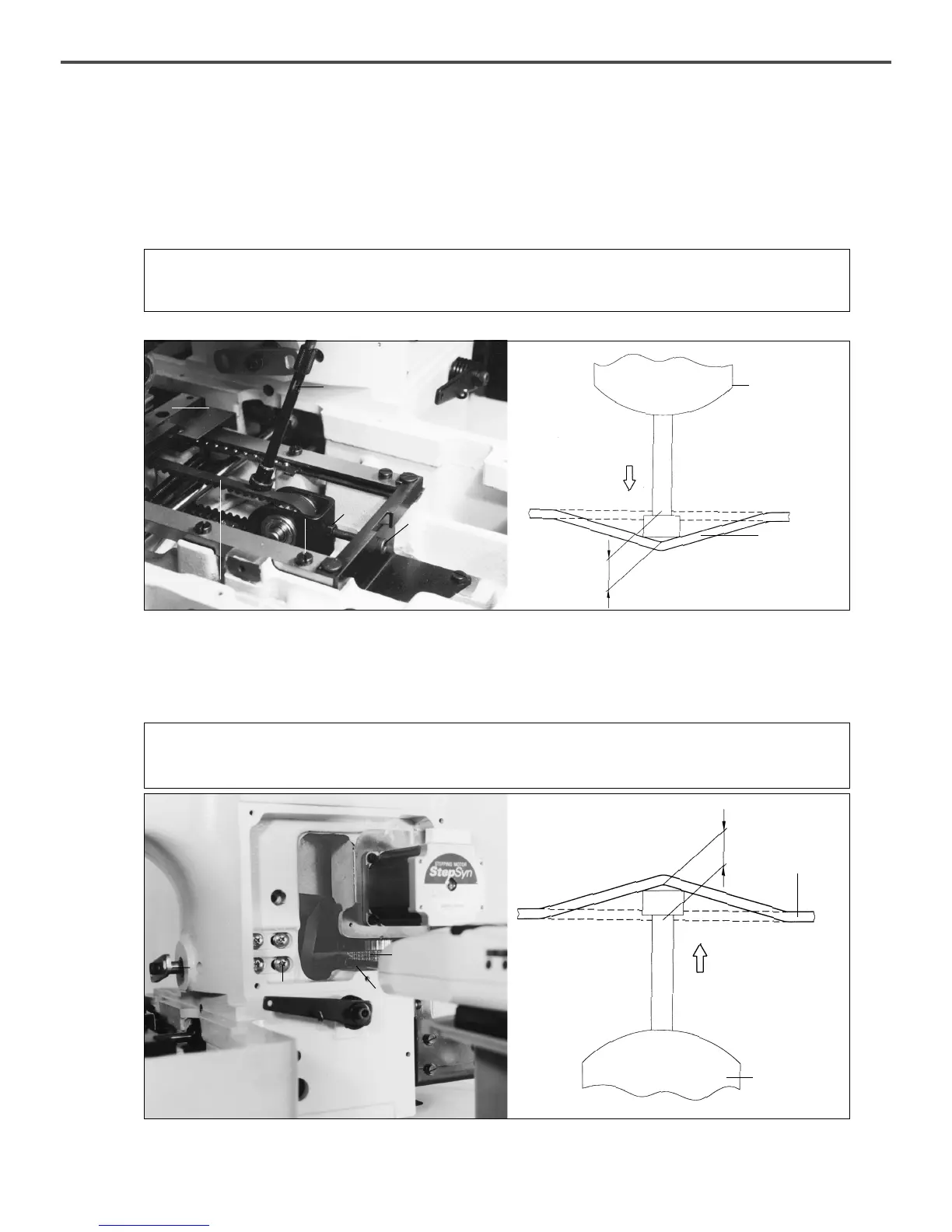

B. Adjusting the tension of the Y-timing Belt

Use the tension gauge to adjust the Y-tension adjustment bolt ① so that 1100g of load is applied 3mm away from

the center of the timing belt. Then, tighten the Y-bracket screw ②.

[ Fig. 50 ]

[ Caution ]

If the timing belt is too tense, the belt may be damaged, and if it is too relax, the transfer in direction Y may

become difficult.

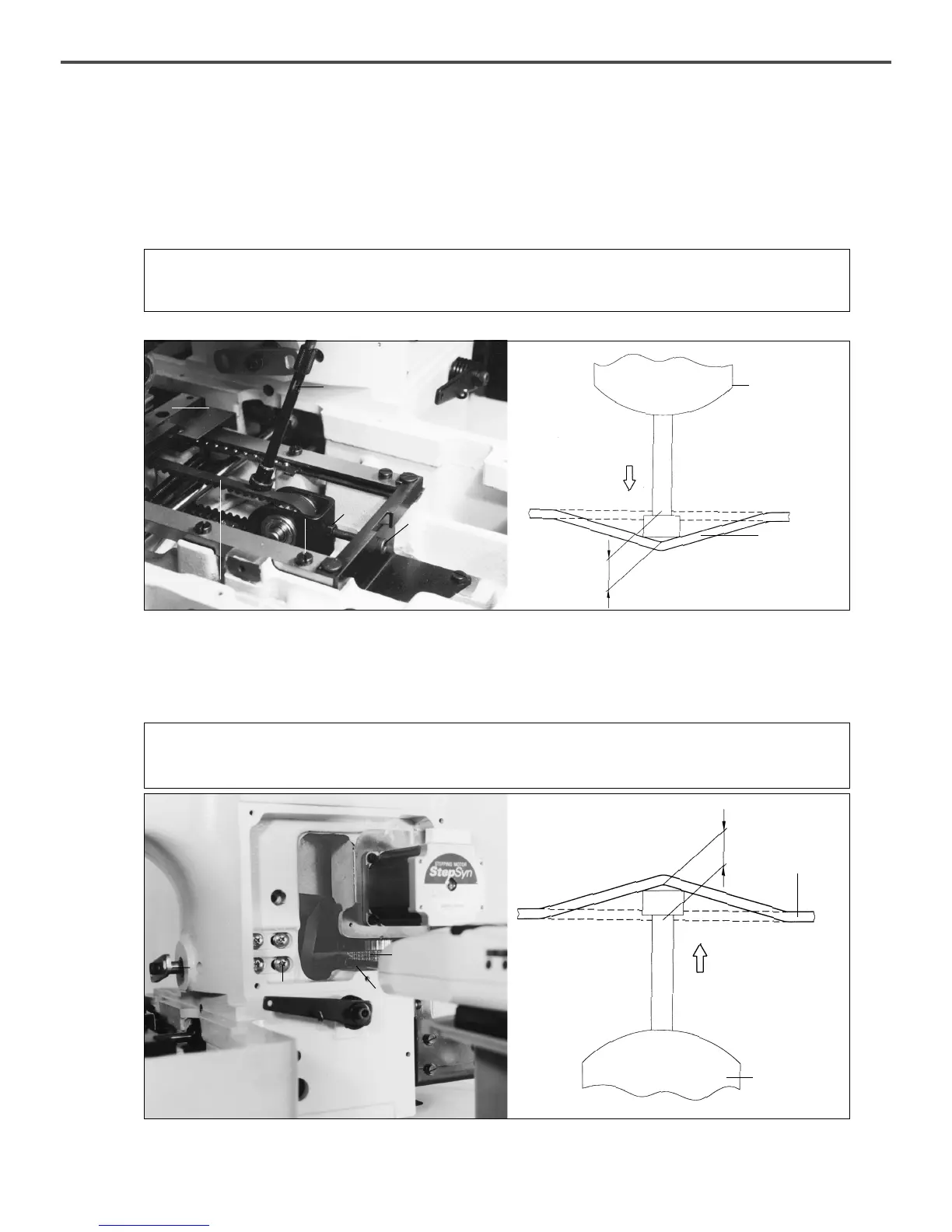

10) Adjusting the X-Y Parts

A. Adjusting the tension of the X-timing Belt

ⓐ Move the race table ① to the left.

ⓑ Use the tension gauge to adjust the X-tension adjustment bolt ② so that 800g of load is applied 4mm longer

on the timing belt. Tighten the nut ③ after the tension is adjusted.

ⓒ Tighten the X-bracket screw ④.

[ Fig. 49 ]

[ Caution ]

If the timing belt is too tense, the belt may be damaged, and if the belt is too relax, the transfer in direction X may

become difficult.

Belt Tension Gauge Belt Tension

Gauge

X Timing Belt

4mm

800g

X-Timing Belt

④

①

②

③

②

Belt Tension Gauge

Y-Timing Belt

①

Belt Tension

Gauge

Y-Timing Belt

3mm

1100g

Loading...

Loading...