16

Mechanical Stationary

Operator’s Manual

300-0804 © 05/2020

SETUP AND CONFIGURATION

Augers

The augers in models 900T, 1000T, 1200T, 1400T, 1600T, 1500TR and 1700TR Supreme Feed Processors rotate at 40 RPM.

If equipped with a VFD auger RPM can be varied during operation.

The augers in models 300, 400, 500, 600, 500T, 600T, and 700T rotate at 46 RPM. If equipped with a VFD auger RPM can be

varied during operation.

Auger speeds are based on a 1200 RPM motor running at 60 Hz.

Horsepower Requirements

The horsepower requirements for your model are based on normal dairy and beef rations. These requirements will vary

depending on the type of ration being processed.

See 35 for the horsepower requirements.

It is recommended to avoid stopping the augers when completely loaded, if at all possible. When a loaded tub is left sitting

for long periods of time the mixed ration will settle in the tub and on auger flighting. The horsepower requirements to

restart the unit will be much higher and possibly cause more stress on the clutch.

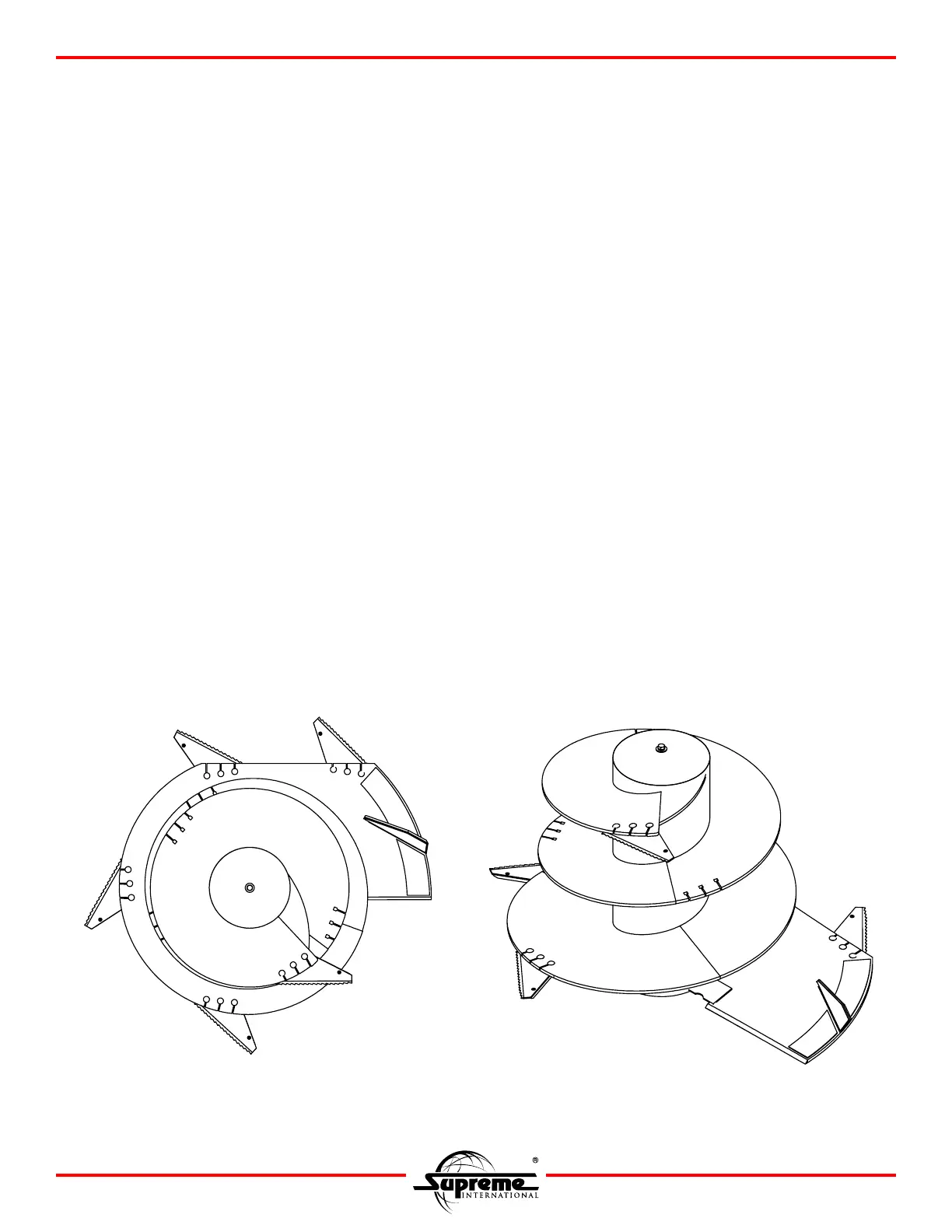

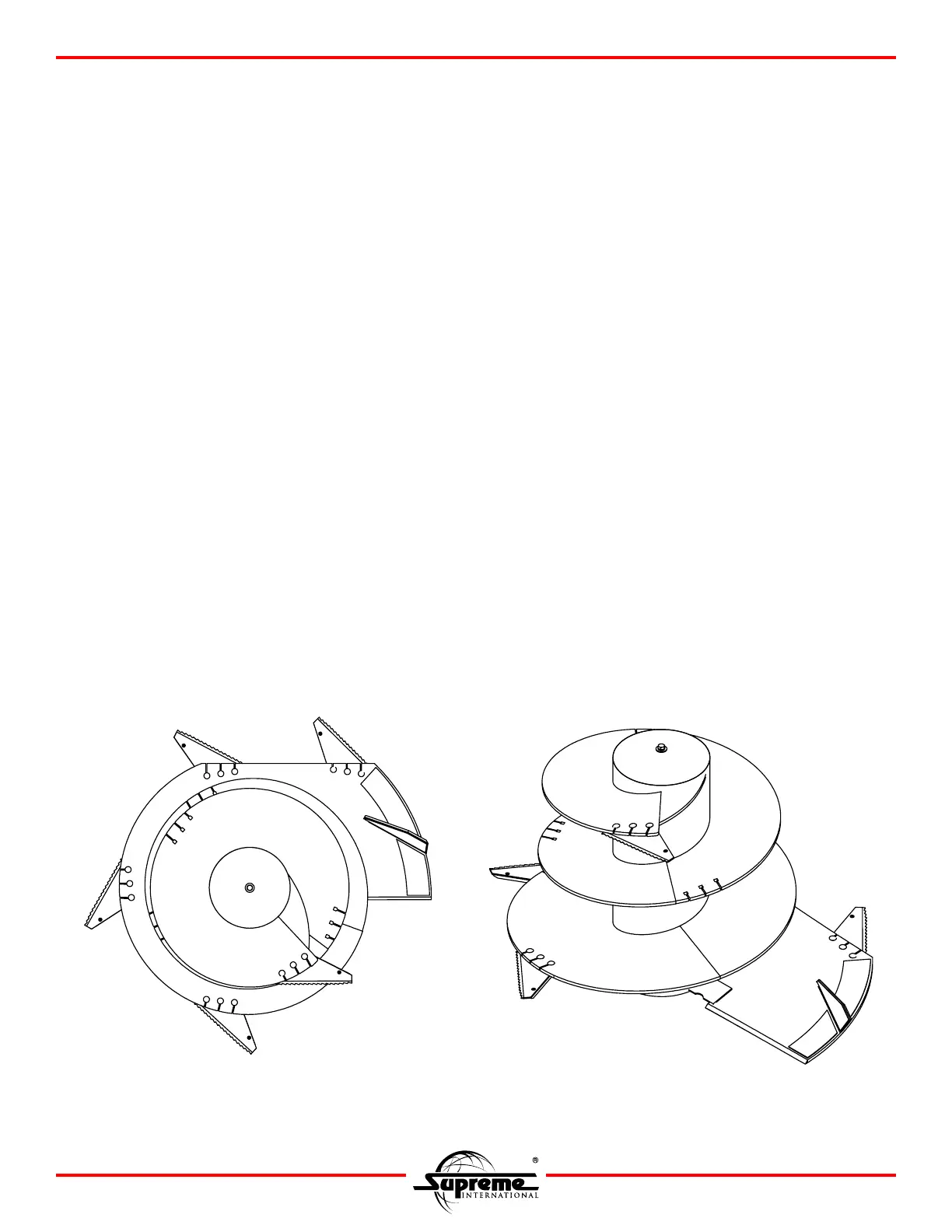

Cutting Knives and Positions

The standard setup for a Supreme Feed Processor comes equipped with five cutting knives per auger (four per auger on

models 300, 400, and 500T).

All augers come with extra pre-cut positions in the auger flighting for additional knife assemblies and/or the re-location of

the existing knife assemblies. Adding, removing and/or changing the existing knife locations may be required to achieve

the desired results. Models 300, 400, 500T, and 600T have six pre-cut positions. The 700T has seven pre-cut positions.

All other models have nine pre-cut positions.

Starting from the bottom of the auger, closest to the tub floor, a knife and backing plate assembly will be bolted to the

auger flighting in each of the first four positions. The fifth knife and backing plate assembly will be bolted to the very top, or

last position, on the auger (see ).

1

2

3

4

9

7

8

5

1

9

3

4

6

7

6

TOP VIEW

ISOMETRIC VIEW

Figure 6

Loading...

Loading...