26

Mechanical Stationary

Operator’s Manual

300-0804 © 05/2020

MAINTENANCE

Gearboxes (Angle, T-Box and two-speed gearboxes inclusive)

The gearbox(es) are detachable from some of the planetary drives and therefore have independent lubricating systems.

The oil reservoir located on the side of the tub is for the planetary drive(s) only. Oil levels for the gearboxes can only be

checked by removing their corresponding “level check plugs.” Approximate oil level requirements for each gearbox are

found in 38.

Models 300, 400, 500, 600, 500T, 600T and 700T units are equipped with an integral, one-piece planetary drive and

gearbox assembly. The oil level supply can be checked at

the sight glass located on the oil reservoir. The sight glass us

marked with safe operating levels. The oil reservoir is located

on the side of the tub.

Oil changes should be performed once a year, or every 1500

hours, whichever comes first. We recommend using an SAE

80/90 EP gear oil in mild climate regions, VG 320 full synthetic

can be used in colder and hotter regions.

Oil Change and Lubrication

The following oil change procedure can be done for all 900T,

1000T, 1200T, 1400T, 1600T, and 1700TR models. The

gearbox of the second cutter.

1. Place an oil pan below the applicable gearbox

2. Remove the level check plug from the gearbox ()

3. Remove the drain plug and drain the oil completely

4. Re-install the drain plug

5. Using a mechanical pump, pump oil into gearbox at the level check plug until it starts to come out

6. Re-install the level check plug

7. Grease zerk found under mounting flange with five (5) pumps of grease

Check all gearboxes for safe oil levels every 2 months, or 100 hours as specified in

36.

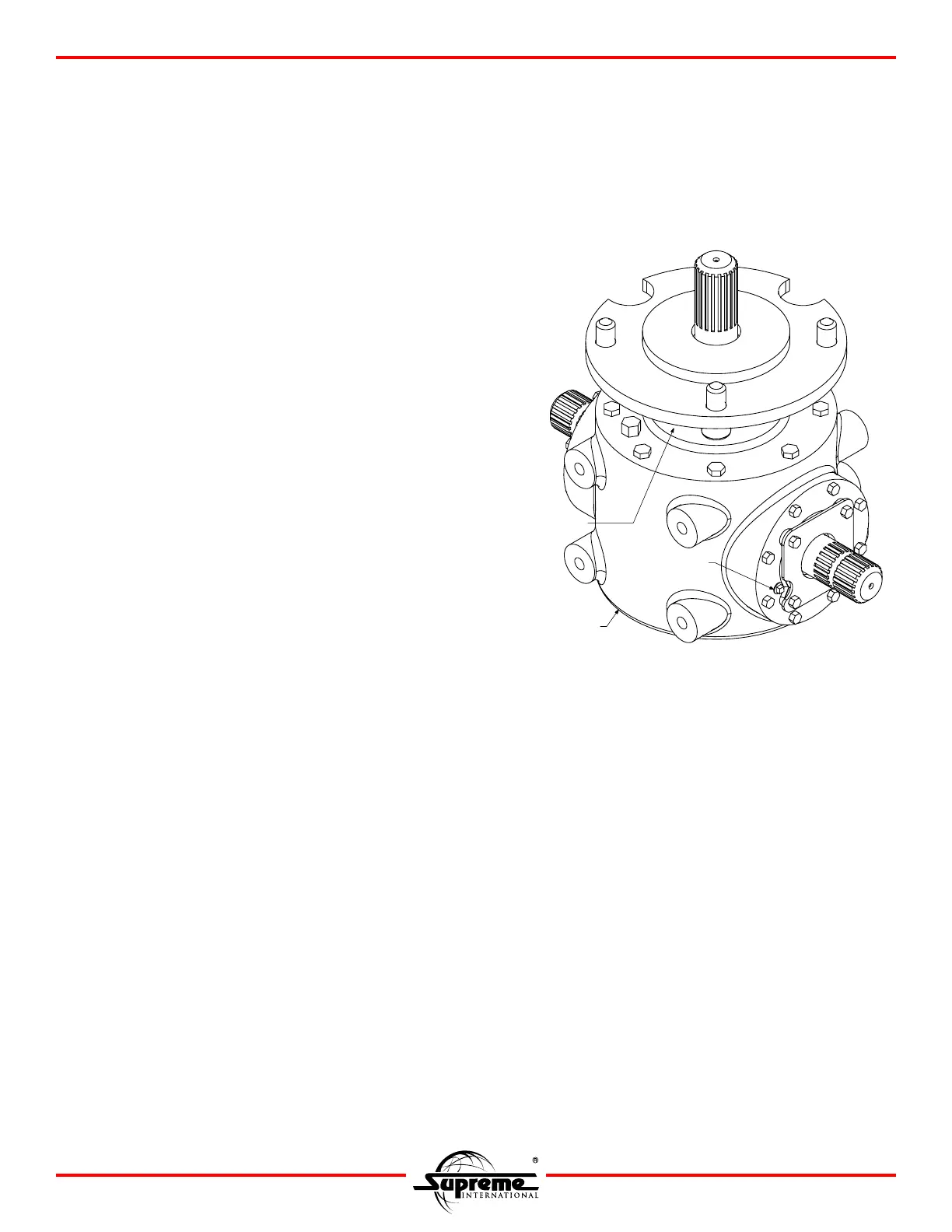

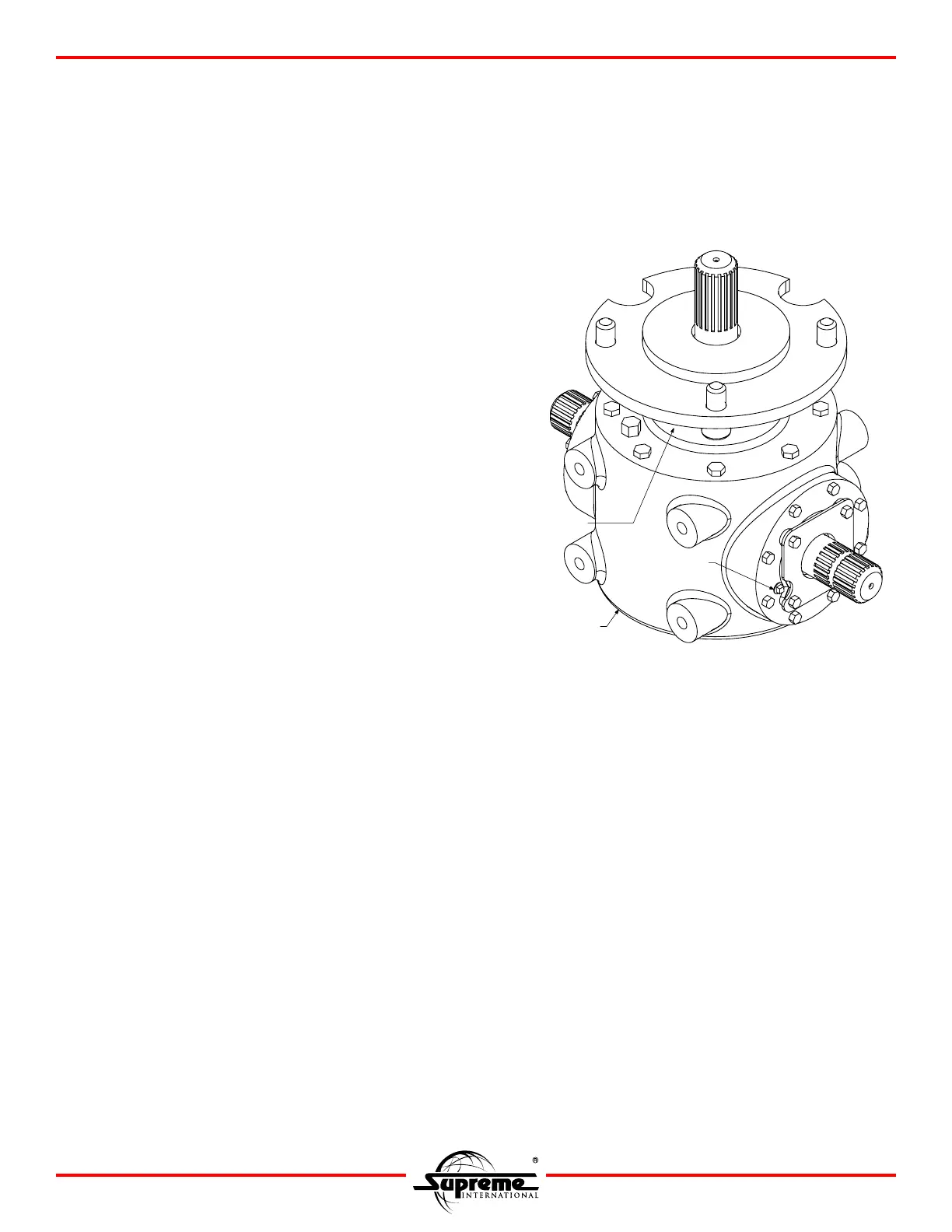

LEVEL PLUG

DRAIN PLUG

GREASE ZERK

Figure 14

Planetary Drives

All oil line fittings for the planetaries and oil reservoir are barbed. These fittings can be removed by unthreading them from

the bushing and/or coupling, while keeping the oil line attached to the fitting. The oil line should spin on the barbed fitting

during removal.

Tools needed for oil change procedure:

• Hand-operated oil pump (if pneumatic, ensure that it is set to less than 10 psi [69 kPa])

• Two oil pans - ensure one pan is capable of holding 6.6 gal (25 liters)

• Gear oil

• Applicable wrenches

Loading...

Loading...