Mechanical Stationary

Operator’s Manual

© 05/2020 300-0804

25

INPUT

INPUT

INPUT OUTPUT

OUTPUT

NOTE:

All yokes on the input shaft and output shaft must be

aligned at the same angle

to ensure the system is balanced.

Failure to do this can cause a vibration in the system and take out shear bolts, U-jo

i

nts and possibl

y

shafts.

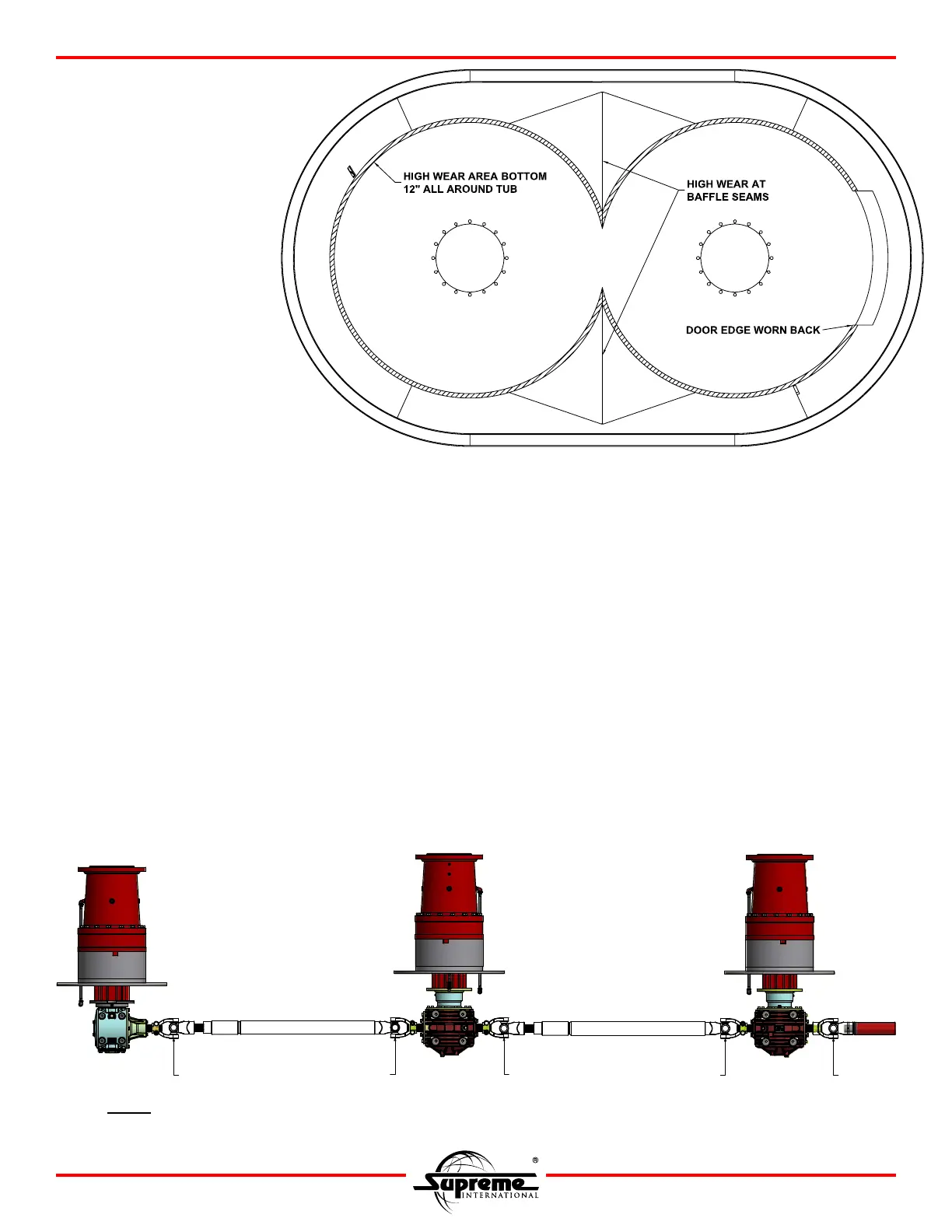

Drive Shaft

The drive shaft connects the electric motor and planetaries together and must be grease at regular intervals.

Final Driveline

The final driveline consists of a telescoping driveshaft, gearboxes (right angle or T-Box - if applicable) and planetary

drives. Maintenance of these components are on the following pages.

Telescoping Driveshaft

The telescoping driveshaft links both gearboxes together and must be greased at regular intervals.

NOTE: The location of all grease zerks are shown on 37

MAINTENANCE

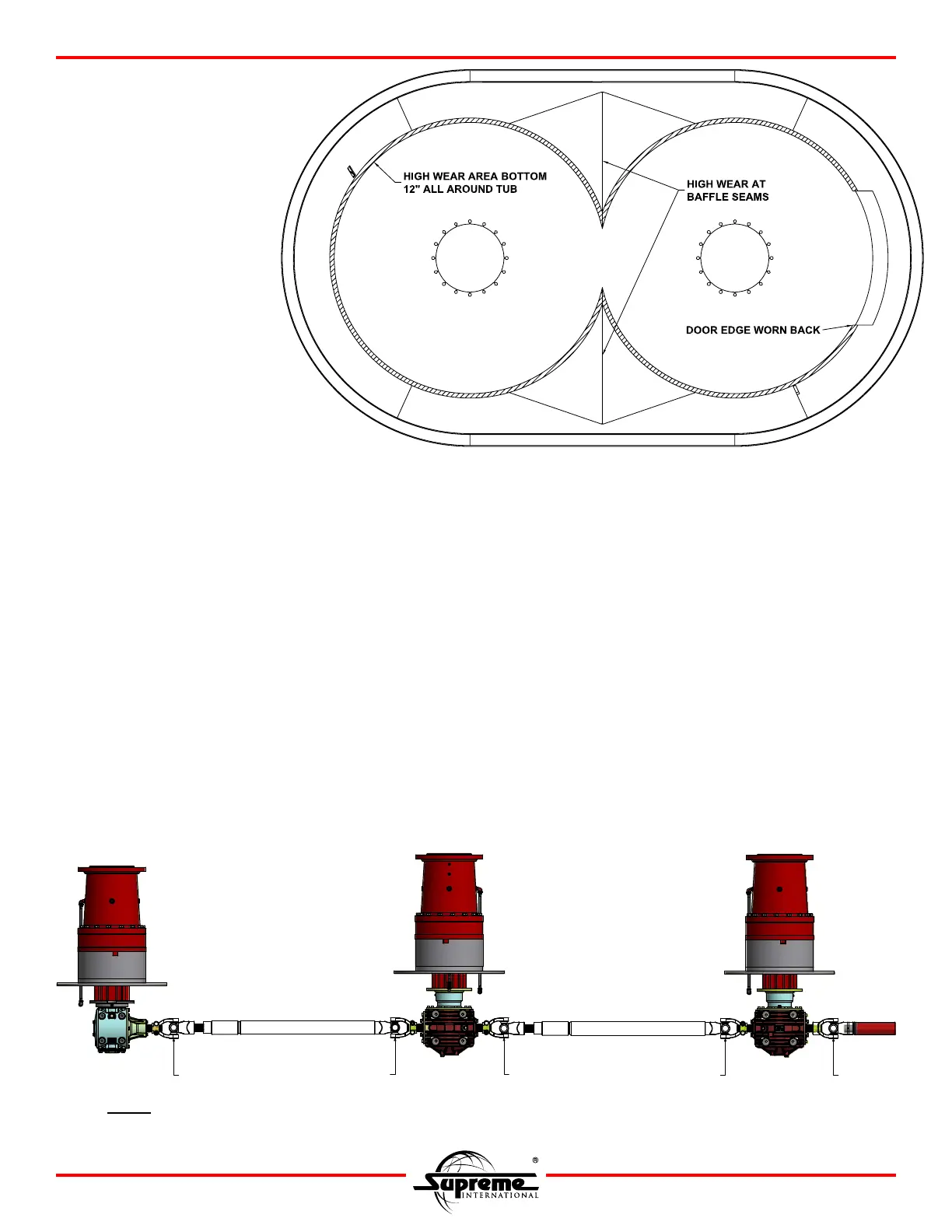

Tub

The tub is nearly maintenance

free. However, lack of care

and attention to tub wear can

lead to increased maintenance

and repair costs.

The rate at which a tub will

wear varies on the

commodities used and the

number of loads it does.

The following signs of wear

indicate that it is time to install a

liner kit. Failure to do so will

render the tub useless shortly there

after when the walls begin to puncture

and spillage of commodities occurs.

• The weld at the baffle seams are nearly worn

off and the baffles are close to separating

• The bottom 12 in (305 mm) of the wall, just above the floor, is thinning out, visible signs of rippling and/or bubbling

can be seen on the outside of the tub where this wear is occurring

• The metal on lower portion of the wall, at the door opening, is worn back and has a sharp edge

NOTE: If any of these signs of wear are visible, call your Authorized Supreme Dealer and have a liner kit installed.

Figure 13

Loading...

Loading...