Mechanical Stationary

Operator’s Manual

© 05/2020 300-0804

17

SETUP AND CONFIGURATION

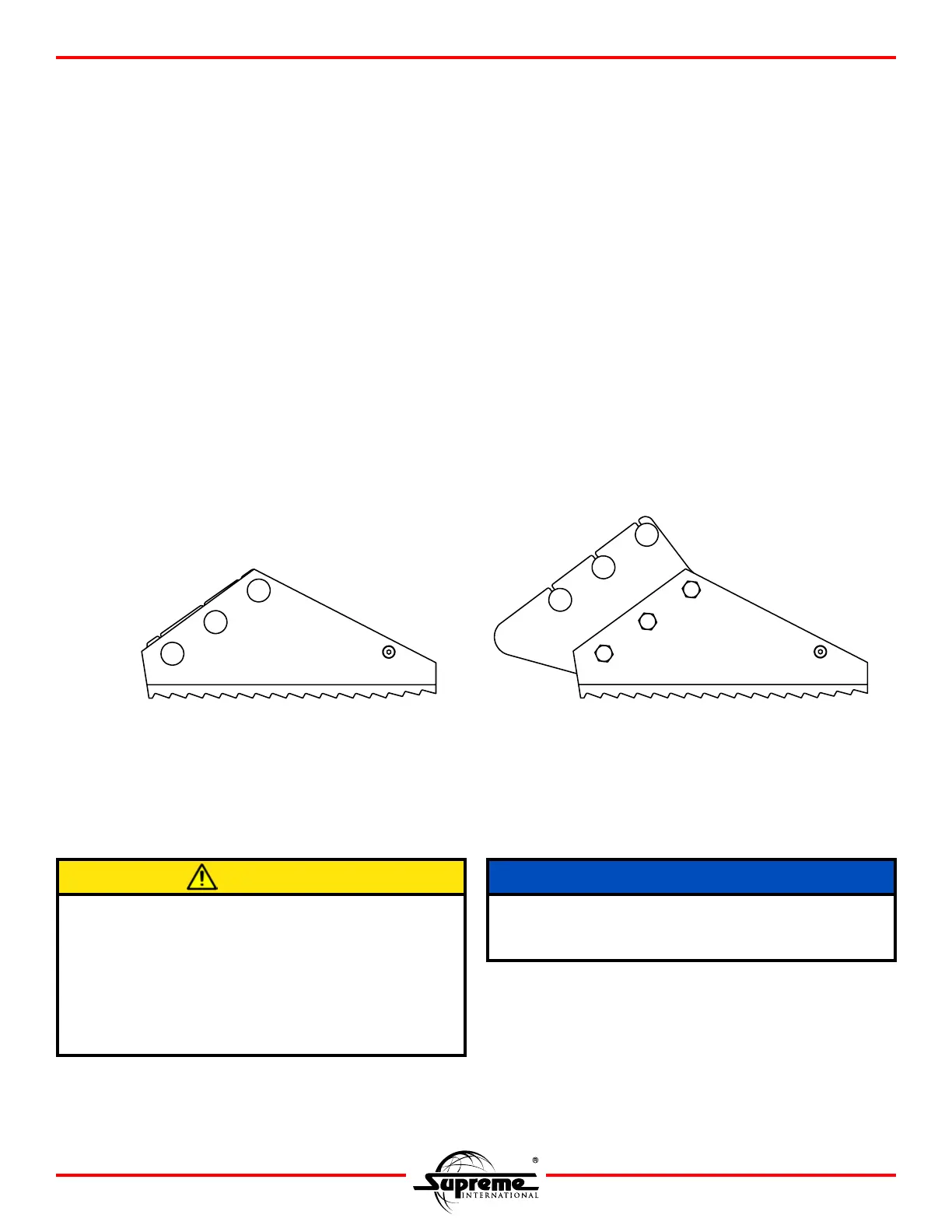

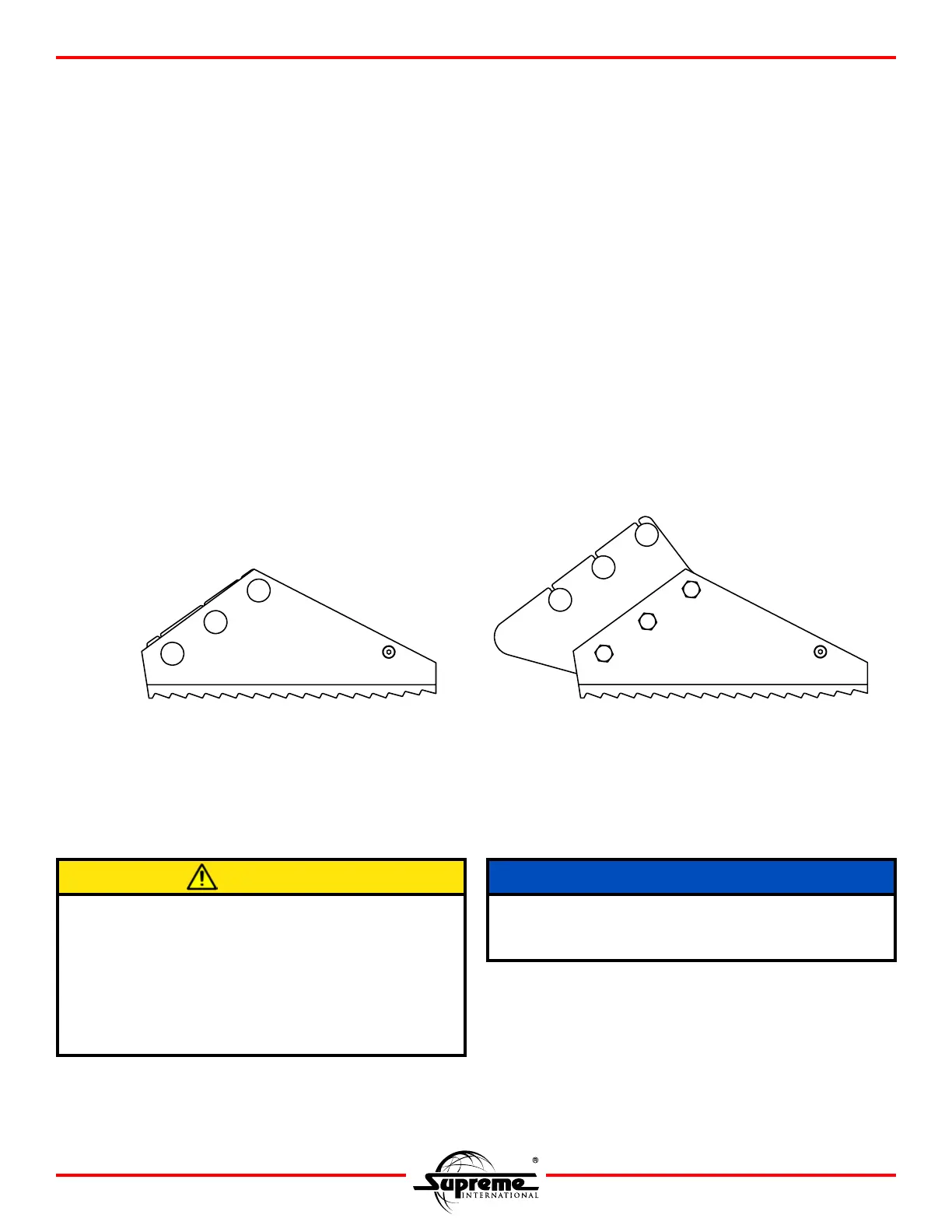

Figure 7

Standard Backing Plate vs Extended Backing Plate

High Roughage Rations

instance the addition of one or possibly two extended backing plates, will aid in the delivery of the ration. In most cases

positioning the extended backing plate in the third or fourth position (or both) will improve delivery; and help to push

material out of the discharge door and ensure the accurate and even delivery of feed.

EXT. BACKING PLATE - KNIFE ASY

STANDARD BACKING PLATE - KNIFE ASSY

EXT. BACKING PLATE - KNIFE ASY

STANDARD BACKING PLATE - KNIFE ASSY

Hard Core Bales

processing the cores of these bales. In most cases the addition of an extra knife assembly to the auger(s) will rectify this

auger. This will allow the knife to cut further into the core of the bale; reducing the processing time.

Extended Backing Plates

In certain applications the addition of extended backing plates can improve the performance of the feed processor. Keep

in mind that adding extended backing plates will cause an increase in horsepower requirements. Never place an extended

backing plate on the very top knife position of an auger.

CAUTION

Never place an extended backing plate on the very

top knife position of any auger. This will cause undue

stress on the upturned portion of the top flighting.

The continuous loading of large, whole, round

and square bales may cause the top portion of he

flighting to bend down, greatly reducing the quality

of mix in the ration.

NOTICE

It is important to note that adding extended backing plates

will cause an increase in horsepower requirements.

Loading...

Loading...