24 - 36

5.4 LED

The lifespan of the LED is 8x higher, which means no need to change the LED very often.The

approved SYLVAC technician will replace the LED when conducting a maintenance service. It will be

necessary to recalibrate the measuring system.

5.5 Limit Switches and Linear Scale Reader

Limit switches and a linear scale reader (encoder) detect the position of slide.

Running the Diagnostics command from the Tools menu will indicate the state of these by using the

gauge it will now be possible to locate and remedy problems with badly set or broken components.

5.6 Calibration values of ‘daily setting piece’

The gauge will have one ‘daily setting piece’ known as a 'setting master', used for calibration before

measurement. The setting piece is of precisely known physical size and is used to check the readings.

The system therefore needs to know the calibrated dimensions as listed on its calibration certificate.

When the setting piece is re-calibrated, which it should be once a year, you will need to type the new

figures into the computer.

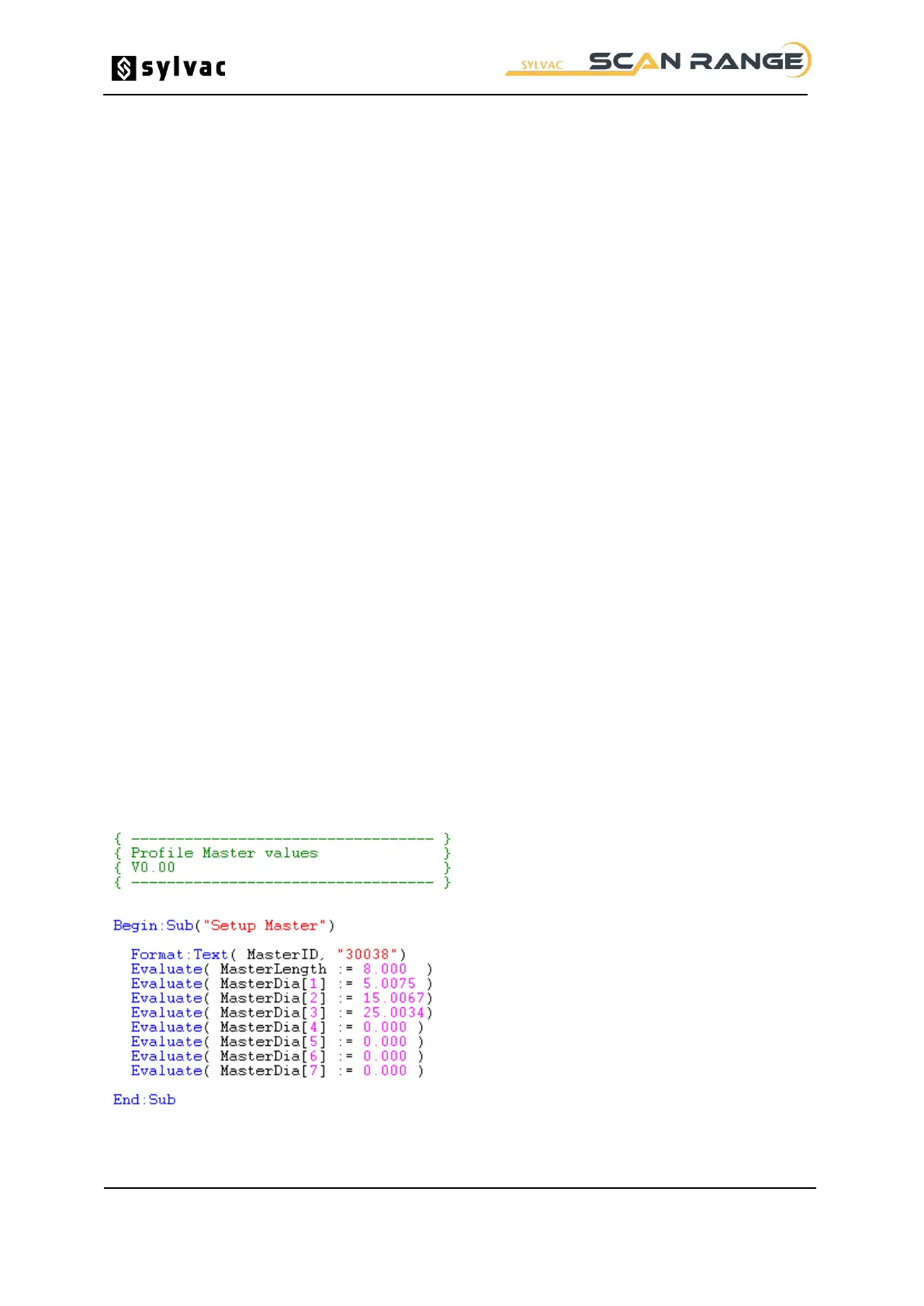

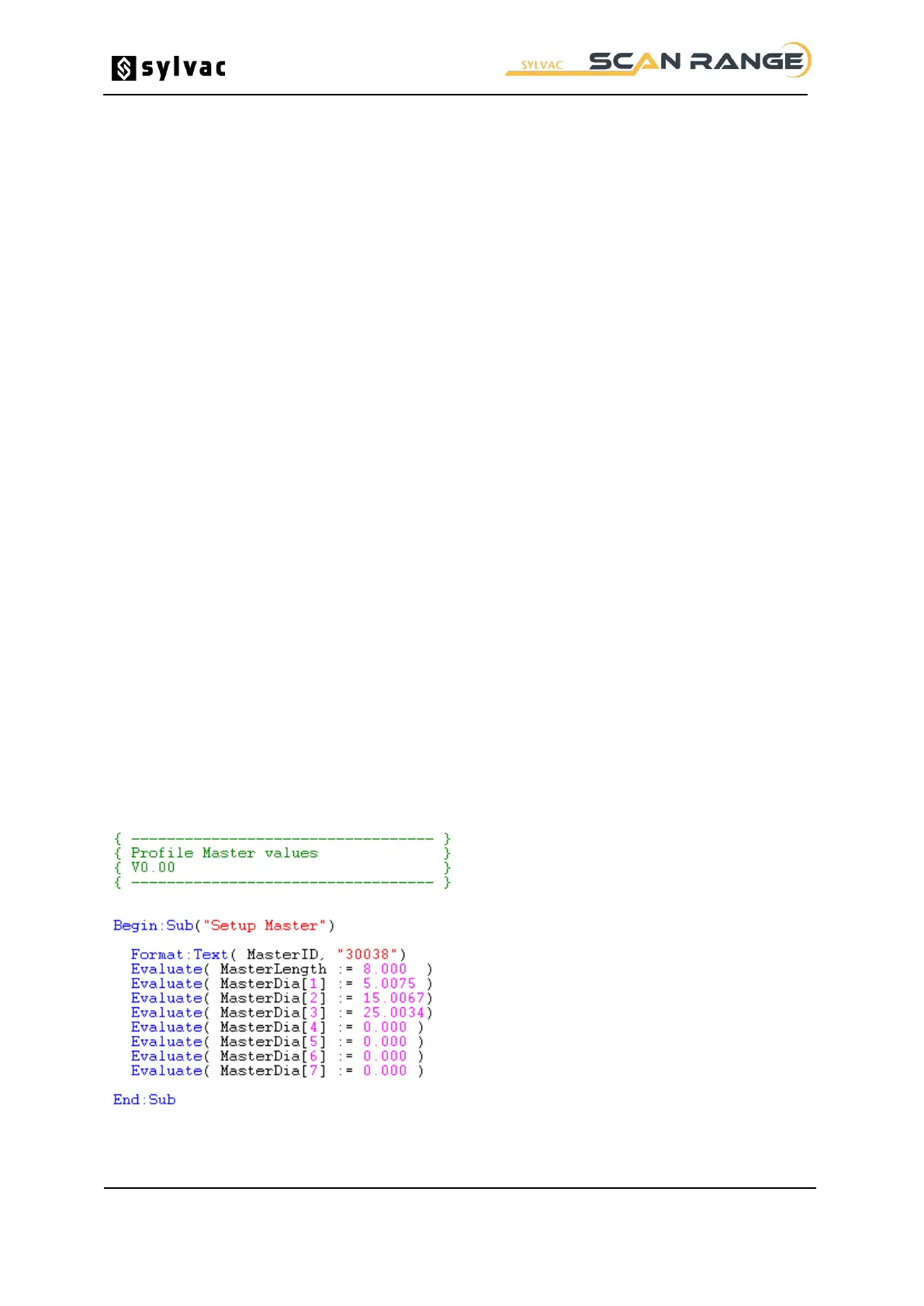

1 The setting piece dimensions are stored in the PROGRAM FILES\PRO-MEASURE\PROFILE

folder, in a file called ‘master.pcl’. This file may be opened using the Pro-Measure Procal Editor

by selecting the Editor Open command from the Tools option off the main menu. Enter the

password if required, and then select the 'master.pcl' file from the file selector.

2 When the file has opened and is visible on the screen, using the editor control keys, you can

now update the calibration values. The 'MasterID' field should correspond to that on the master

certificate to identify that you have the correct details. The remaining lines contain the setting

piece dimensions. Enter the values into the appropriate fields such that the file contents match

the certificate. Do not change the order of the lines in the program.

3 After you have typed in all the values, save the file using the Save command. When prompted,

choose YES to save your changes.

The 'master.pcl' file will look similar to the following.

Note : Some gauges do not require all of the MasterDia fields. Those not required will have a value of

0.000. The actual value in the MasterDia fields starts with the smallest on the first line and ends with

the largest, each following line being larger than the previous. This order must always be maintained.

Loading...

Loading...