Taco® SKV

14

302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

8.3.5 Motor Connection

DANGER: INDUCED VOLTAGE! Run out-

put motor cables from multiple adjustable

frequency drives separately. Induced voltage

from output motor cables run together can

charge equipment capacitors even with the

equipment turned off and locked out. Failure

to run output motor cables separately could

result in death or serious injury.

• For maximum wire sizes, see “17.1 Power-depen-

dent Specifications” on page 75.

• Comply with local and national electrical codes for

cable sizes.

• Motor wiring knockouts or access panels are pro-

vided at the base of IP21 and higher (NEMA1/12)

units

• Do not install power factor correction capacitors

between the adjustable frequency drive and the

motor

• Do not wire a starting or pole-changing device

between the adjustable frequency drive and the

motor.

• Connect the 3-phase motor wiring to terminals 96

(U), 97 (V), and 98 (W).

• Ground the cable in accordance with grounding

instructions provided.

• Follow the motor manufacturer wiring requirements

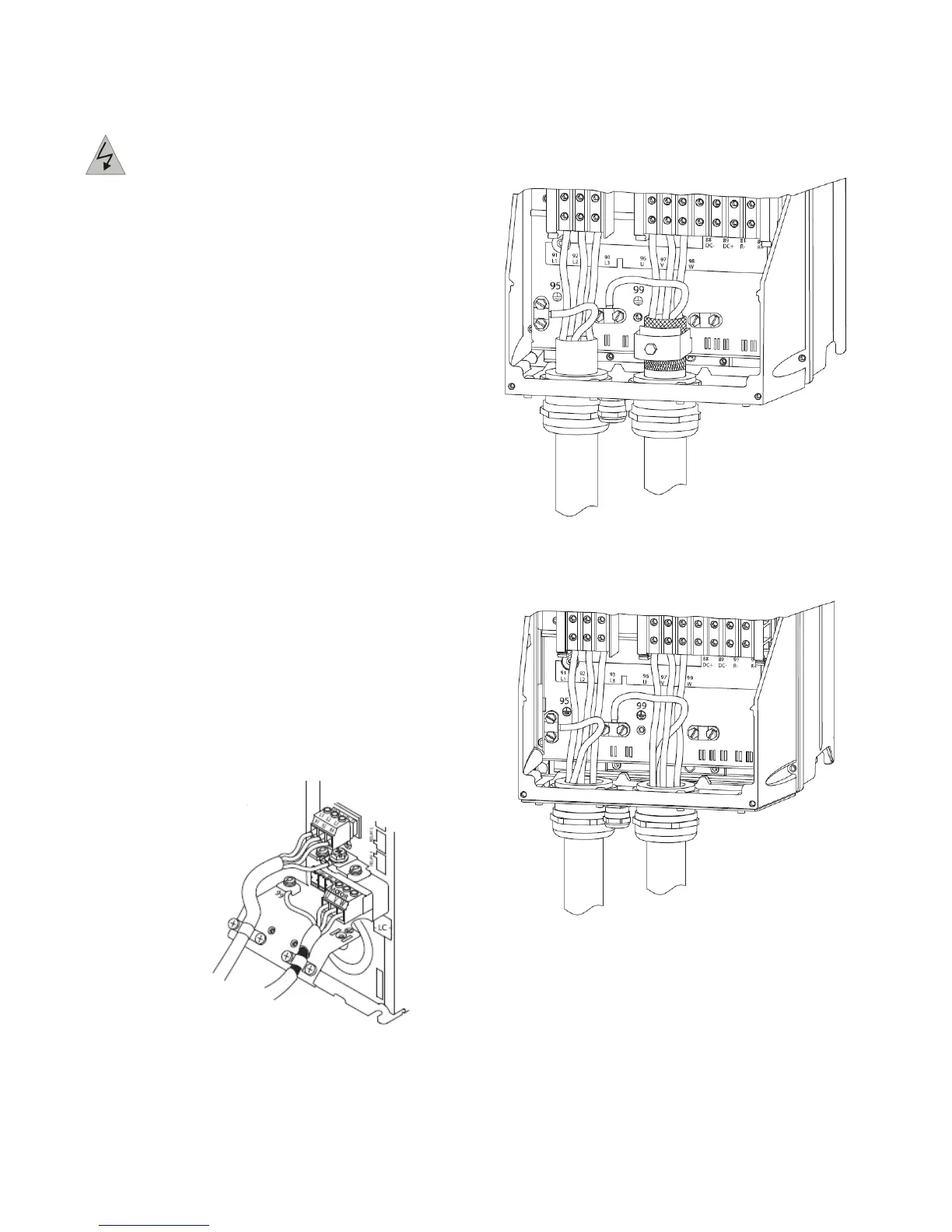

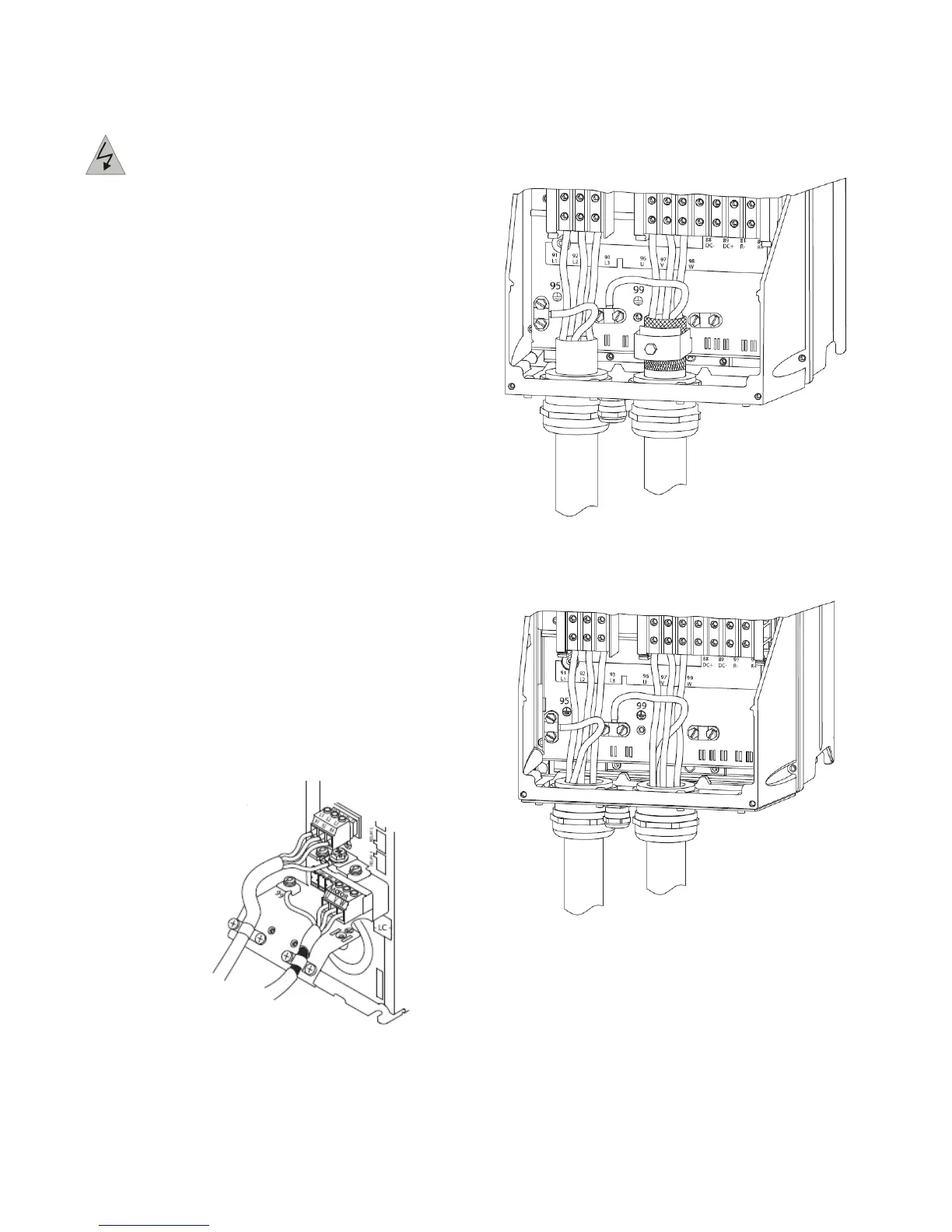

The three following figures represent line power input,

motor, and grounding for basic adjustable frequency

drives. Actual configurations vary with unit types and

optional equipment.

Figure 8-8: Motor, Line Power and Ground Wiring

for A-Frame Sizes

Figure 8-9: Motor, Line Power and Ground Wiring

for B-Frame Sizes and Above Using Shielded

Cable

Figure 8-10: Motor, Line Power and Ground

Wiring B-Frame Sizes and Above Using

Shielded Cable or Conduit

8.3.6 AC Line Power Connection

Size wiring based upon the input current of the adjustable

frequency drive.

• Comply with local and national electrical codes for

cable sizes.

• Connect 3-phase AC input power wiring to terminals

L1, L2, and L3 (see Figure 8-11).

Loading...

Loading...