Taco® SKV

38 302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

Menu.”

6.Scroll down to Parameter 0-10 Active Set-up

and press OK.

7.Change Active Set-up to “Set-up 1”.

a.Parameter 0-10 Active Set-up.

b.You will know the change has happened when

you see change to .

8.Press the [Status] button to get back to the main

screen.

9.Close the discharge valve before starting pump.

DANGER: MAKE SURE SUCTION VALVE

IS OPEN!!

10.Press the [Auto on] button.

11.Once the pump has started, open the discharge

valve slowly.

CAUTION: Do not operate pump for pro-

longed periods with discharge valve closed,

to avoid overheating and potentially damag-

ing loads.

12.After the discharge valve is fully open, let the

drive ramp up to the design flow point that was

specified.

IMPORTANT: Allow the pump enough time

to settle out at the specified design flow.

11.4 Verify Flow

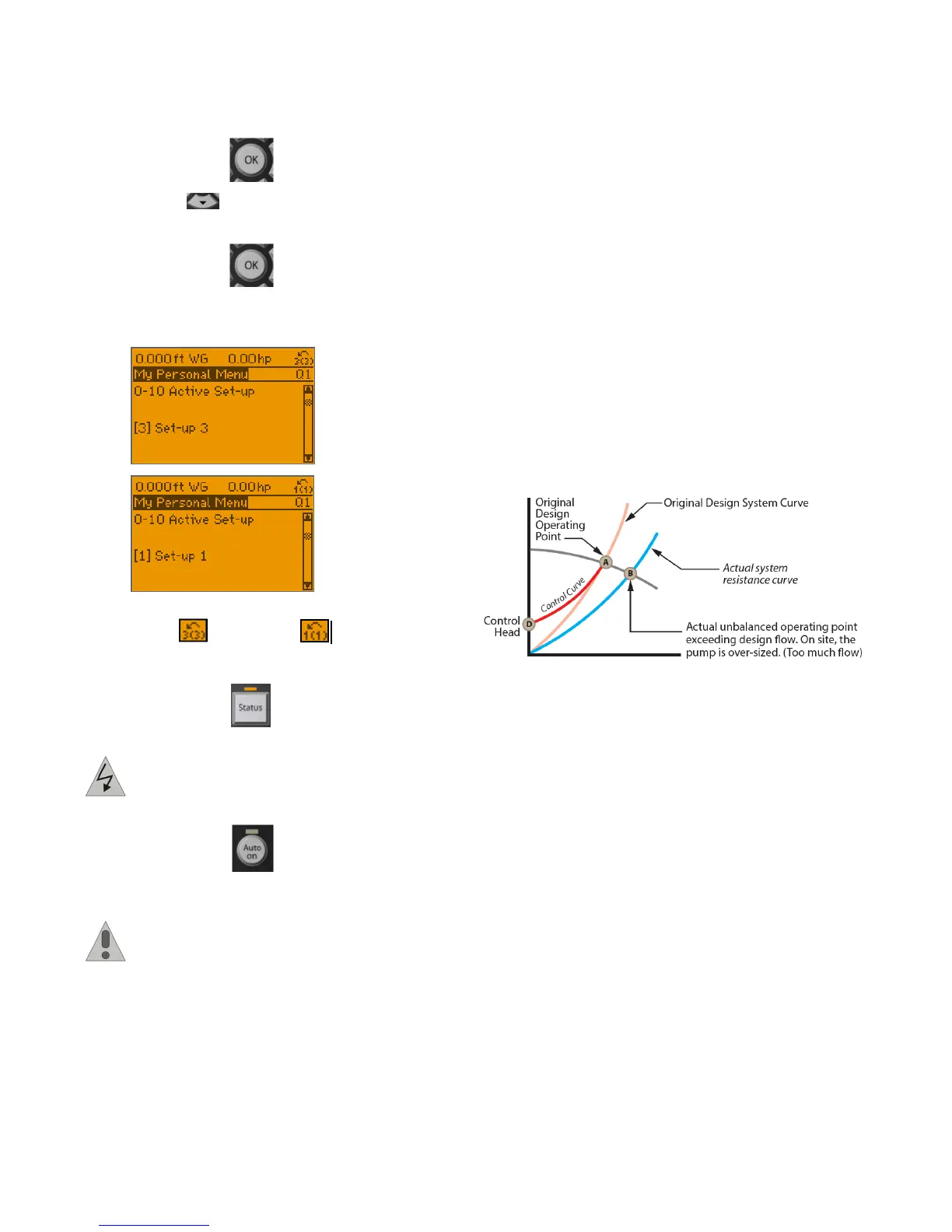

The VFD is factory programmed with the Design Pres-

sure Head and Design VFD Speed that were indicated at

the time of order.

If this pump was ordered for a system distribution pump

(quadratic system curve), it ships in Set-up 1 (it will track

a system control curve like the one shown in Figure 10-

1).

Follow the steps below to determine whether the pump is

producing the required amount of flow.

13.Close zone valves to ensure pump speed slows

as demand is reduced. Then open the valves to

ensure the pump increases speed until it reaches

the desired flow.

14.If the pump is not meeting the desired flow condi-

tions, as shown in the figure below, see “12 System

Balancing” on page 39.

Figure 11-1: Over-sized Pump Example

Before

After

Loading...

Loading...