Taco® SKV

78 302-365, Effective: June 5, 2017

© 2017 Taco, Inc.

APPENDIX A: SET-UP FOR STANDBY PUMP ALTERNATION

This section describes how to alternate Taco SKV pump units based on elapsed time and how to configure the standby

pump to energize in the event that the duty pump fails.

A.1 Overview

Two identical drives are used; one installed on each pump. One drive is configured as the “lead” drive and the other as

the “standby” drive, but both drives participate equally in the alternation. The “lead” drive is the drive that controls the

alternation process. If one drive enters an alarm condition, the other automatically assumes operation. Alternation

attempts do not occur when one drive is in alarm.

This system requires one set of dry contacts for start/stop. Twenty-four VDC control voltage from both drives is wired to

the lead drive’s relay 1. If the lead drive’s control circuitry is working, it supplies power. If the lead drive cannot provide

control voltage, the standby drive automatically assumes control.

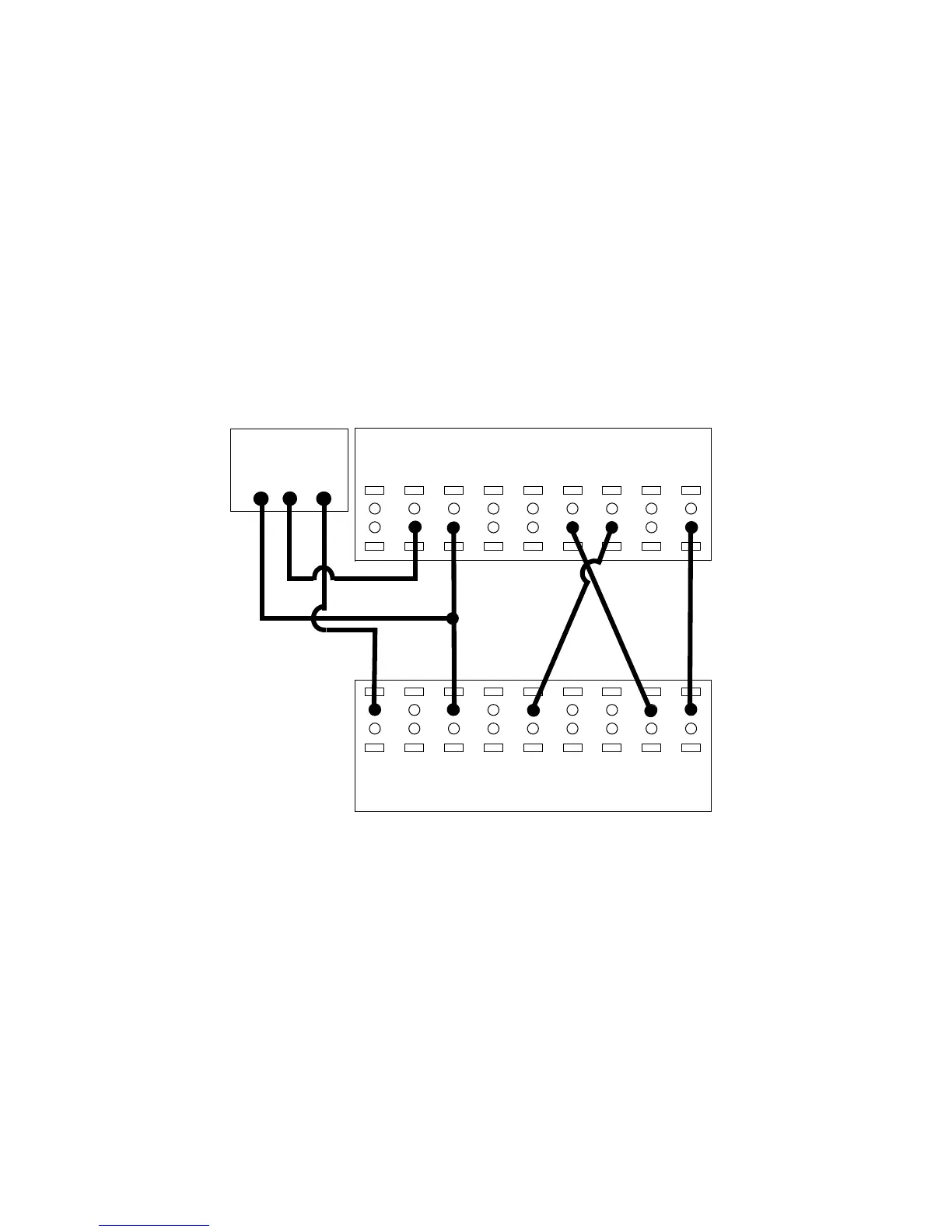

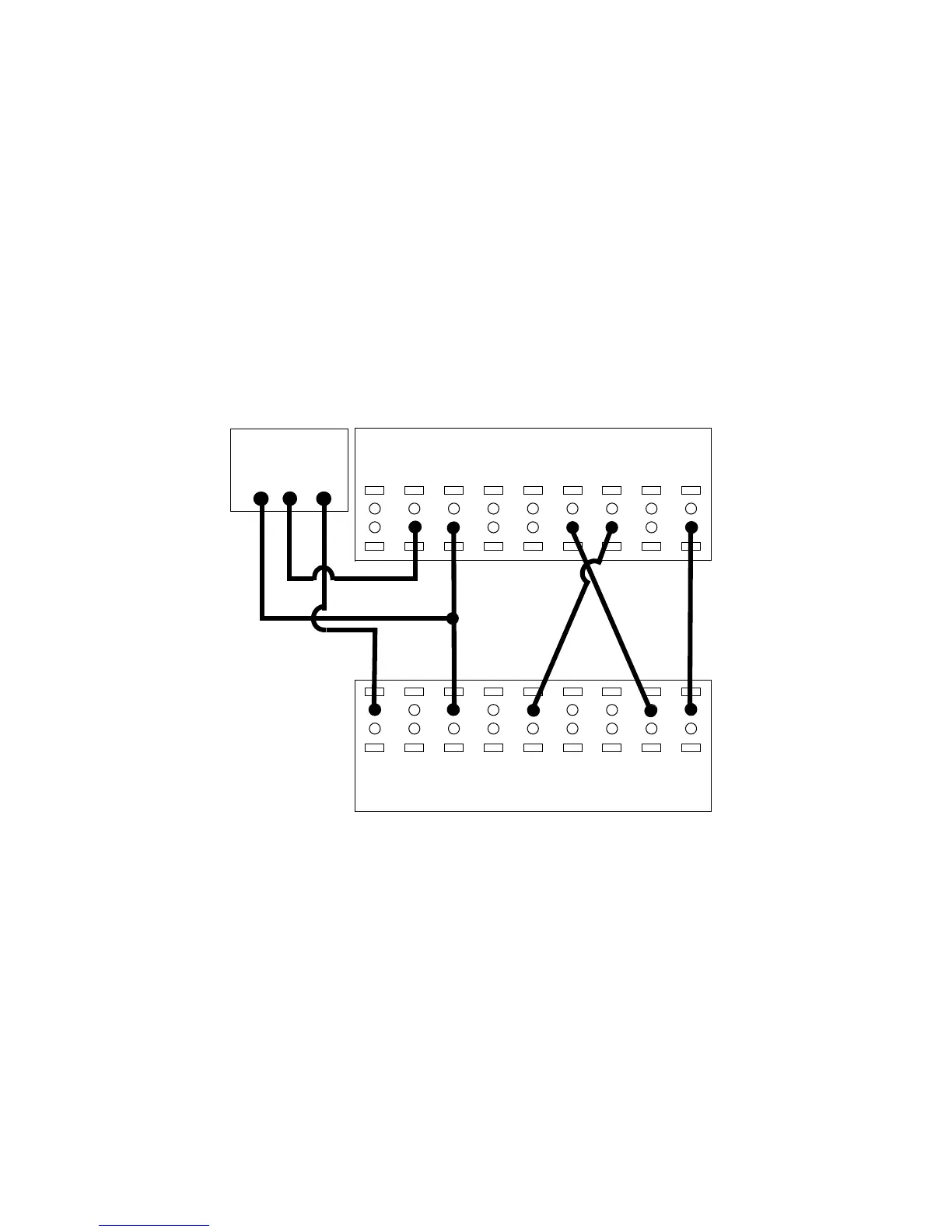

Figure A-1: Wiring for 2x0 Pump Alternation

No external monitoring is needed. Pump alternation is controlled by the active set-up of each drive. The active set-up is

controlled by the lead drive.

• Under normal conditions, the lead drivechanges its active set-up based on the time delay specified in timer 0 by

parameter setting 13–20.0.

• When the lead drive is operating normally in set-up 1, its digital output 29 is high. This state puts the standby drive

into set-up 2.

• When the lead drive is operating normally in set-up 2, its digital output 29 is low. This state puts the standby drive

into set-up 1.

• If the lead drive encounters an alarm condition or loses power, its digital output 29 is low. This state puts the

standby drive into set-up 1, allowing it to take over operation.

• If the standby drive encounters an alarm condition or loses power, its digital output 27 is low. This condition causes

the lead drive to move into set-up 1, allowing it to take over operation.

12

+24V

13

+24V

18

D IN

19

D IN

27

D IN

29

D IN

32

D IN

33

D IN

20

COM

I/O Digital

01

COM

Relay 1

02

NO

03

NC

Drive 1

12

+24V

13

+24V

18

D IN

19

D IN

27

D IN

29

D IN

32

D IN

33

D IN

20

COM

I/O Digital

Drive 2

Loading...

Loading...